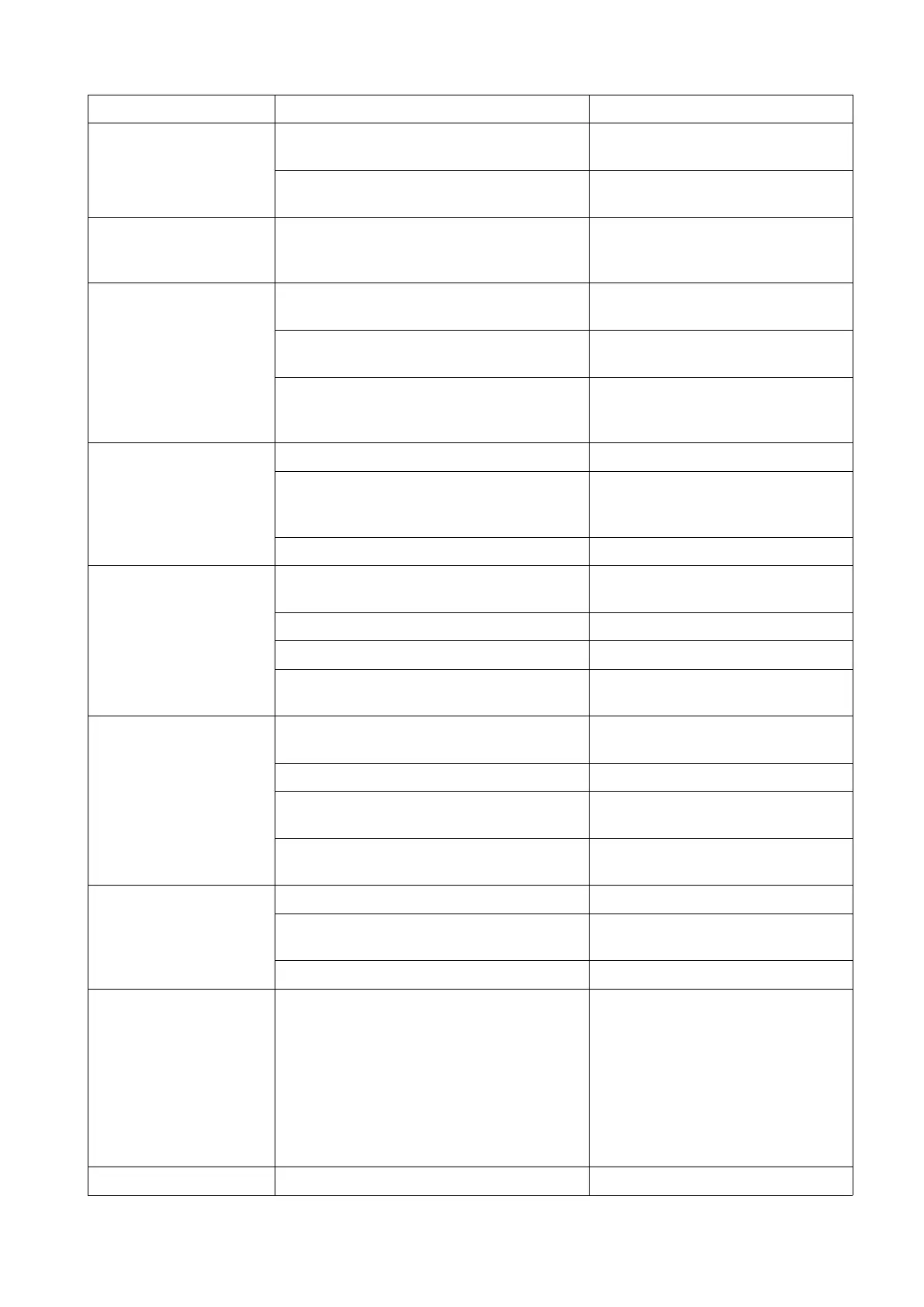

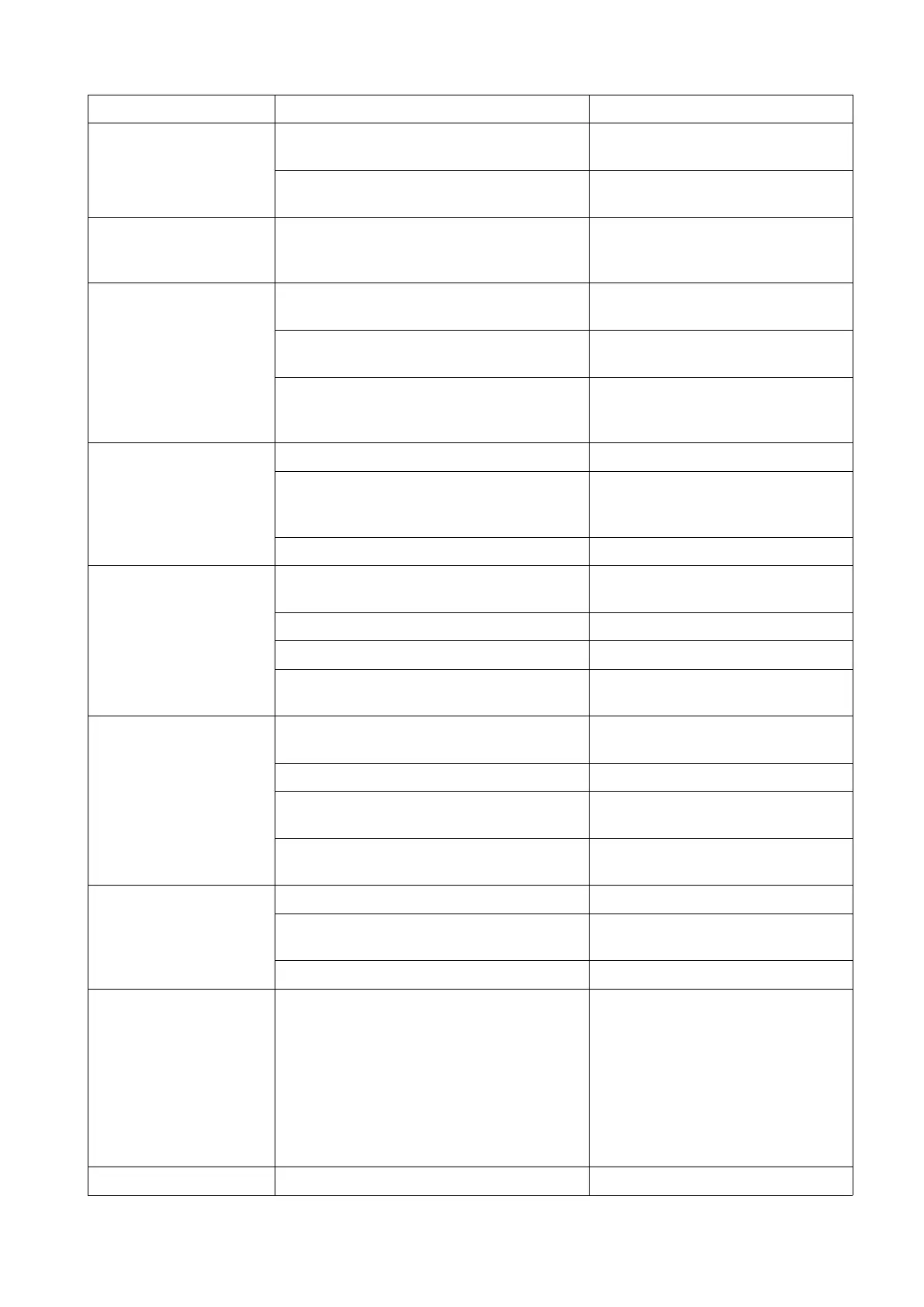

The sealing component of central rotation

connector is aged and damaged.

Change the sealing component

The left and right crawlers are of different

tightening.

Boom (bucket rod and

bucket) move to one

direction only.

Main valve core is stuck or valve rod spring

breaks.

Boom (bucket rod and

bucket) does not move.

Boom valve rod is stuck or of low

overloaded pressure

Fuel supply pipe leaks, detached, O ring

damaged or pipe fitting is loose

Change the damaged component

Sandstone in main valve or the low pressure

chamber is connected to the high pressure

chamber

Boom (bucket rod and

bucket) drops too quick

or the cylinder drops at a

certain height even it is

not operated due to dead

weight

Low overloaded valve pressure

Serious internal leak of cylinder

Change the sealing component, repair

the inner wall or groove of cylinder

or change the cylinder.

Loose oil pipe fitting, damaged O ring

Boom (bucket rod and

bucket) works

powerlessly

Serious internal leak of multiway valve or

sandstone inside it

Serious internal leak of oil cylinder

The main valve is disabled due to internal

leak.

Boom (bucket rod and

bucket) moves even it is

not operated

Multiway valve core is stuck or serious

internal leak

Multiway valve rod spring breaks

Leak of working cylinder, or the working

device drops due to dead weight

Low pressure of overload overflow valve or

the spring breaks

Adjust to specified pressure. Change

the spring if it is broken.

Wrong grade of hydraulic oil for excavator

Hydraulic oil cooler surface is polluted by oil

and dirt, which blocks the air hole.

Low oil level of hydraulic oil tank

The hydraulic components such as motor,

main valve and oil cylinder or sealing

components are seriously worn and cause

internal leak, which increases the oil

temperature. Traveling rotation and working

device are delayed and powerless. The hot

temperature degrades the hydraulic oil. The

safety valve is of poor air tightness, which

leads to overflow.

Change the elements in time

No action of rotation (no

Hydraulic oil pipe breaks

Loading...

Loading...