PRINCIPAL OF OPERATION

All models of the Webster

®

Hardness Tester

operate in the same manner. The material to be

tested is placed between the anvil and the pen-

etrator. Pressure is applied to the handles until

“bottom” is felt at which time the dial indicator is

read. Excess handle pressure beyond this point

is not harmful but is unnecessary.

The Tester should be held still while taking the

reading as any twisting or other movement

during testing will result in untrue readings as

experienced with any other hardness testing

machine.

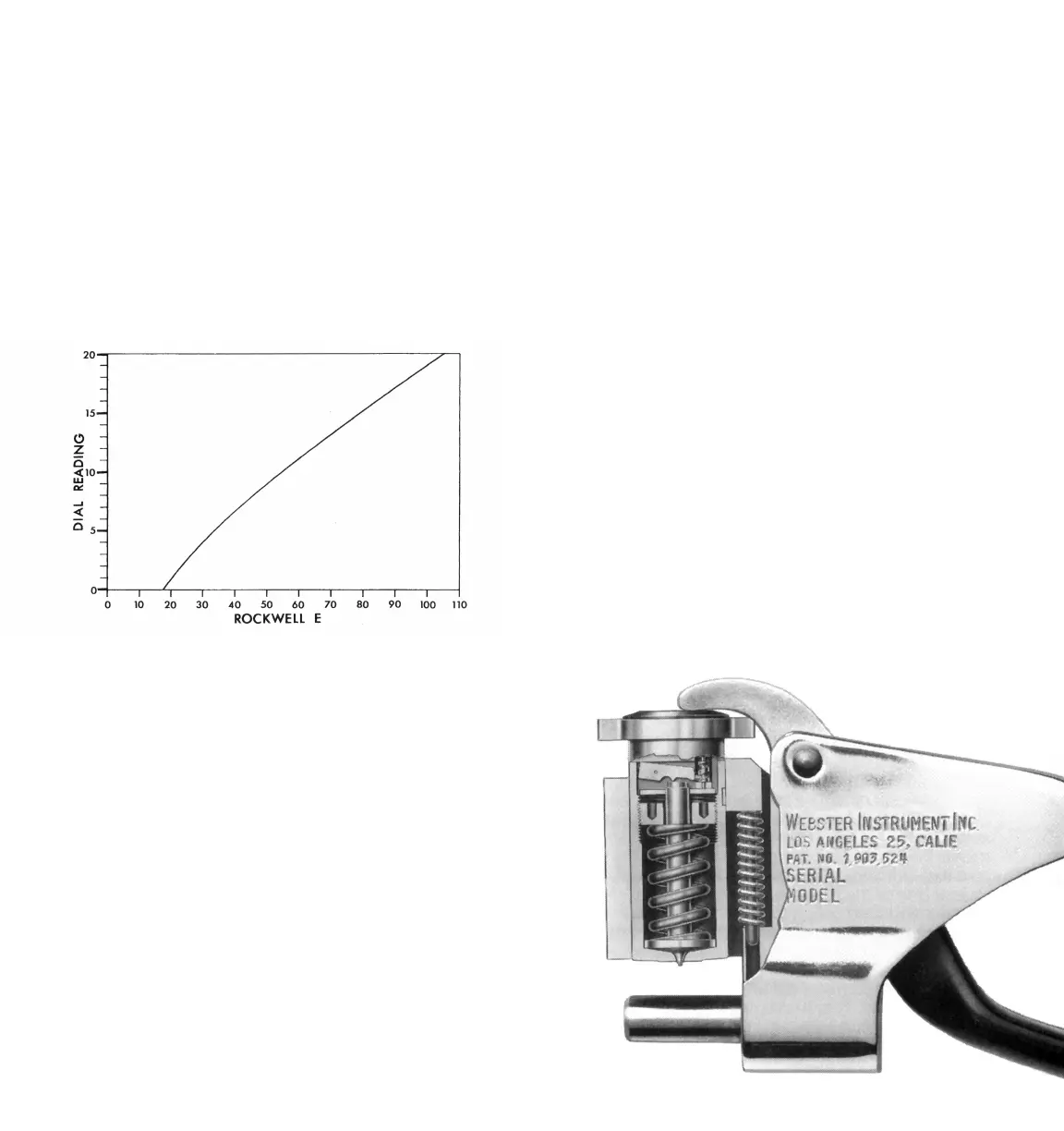

By reference to cutaway view Fig. 1 it will be

seen that the principal working parts are con-

tained in the penetrator assembly. The pene-

trator assembly consists of the penetrator, load

spring, adjusting nut, penetrator housing, hous-

ing key, return spring and dial indicator. This

entire assembly moves toward the anvil as a unit

when pressure is applied to the handles.

As handle pressure is applied and the penetra-

tor assembly moves toward the material, the

penetrator point makes contact rst because

it projects beyond the at face of the housing.

Continued

Fig. 1

SPECIAL INSTRUCTIONS FOR THE

WEBSTER

®

MODEL BB-75 TESTER

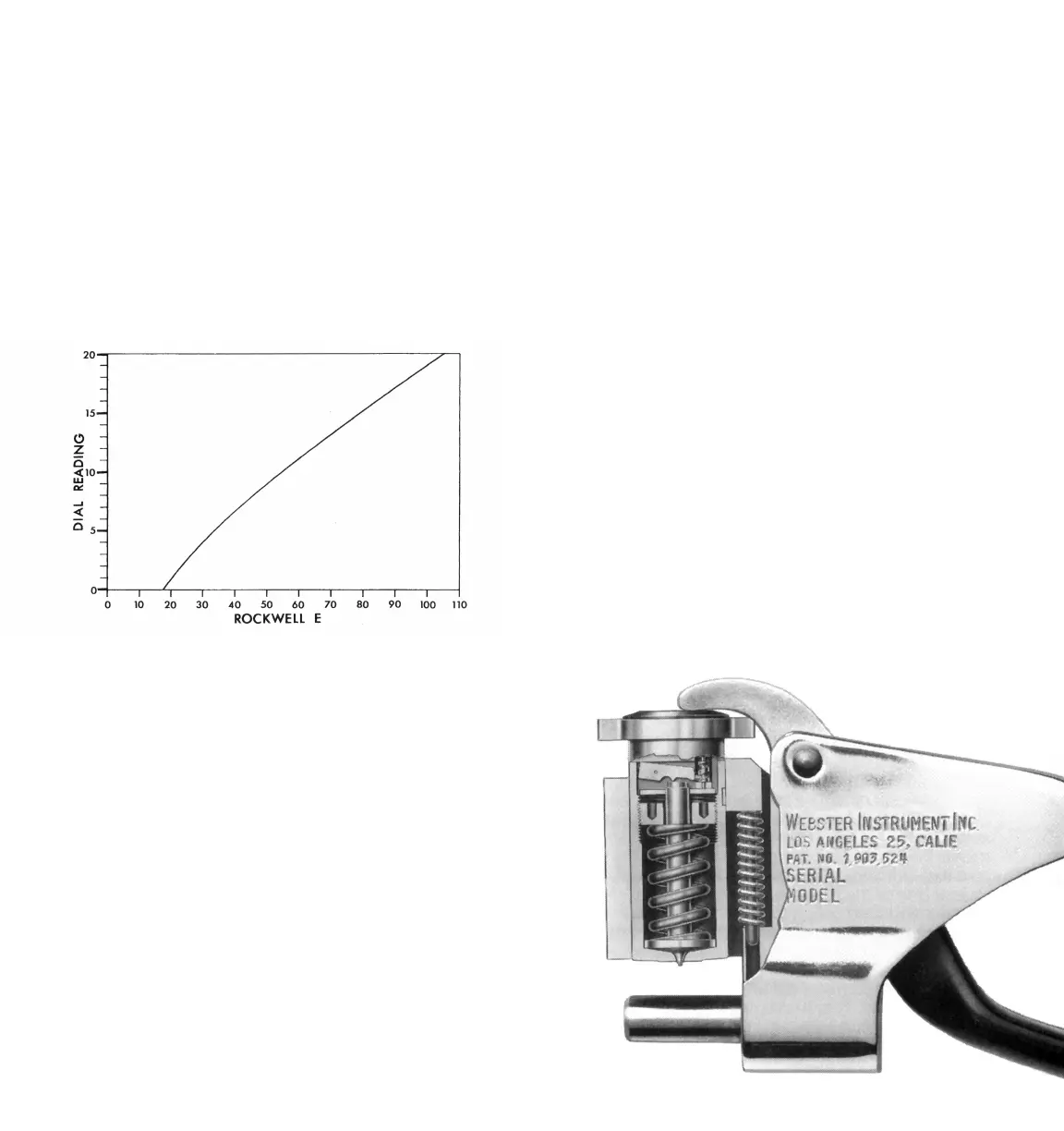

The Model BB-75 Tester is a combination of the

Model B-75 penetrator and the Model B load

spring. This combination provides slightly more

sensitivity on the softer materials than the B and

B-75. The Model BB-75 was developed to answer

the need of certain industries for rapidly testing the

hardness of electro-deposited copper and copper

in the low hardness range. When adjusted prop-

erly the readings obtained on copper samples are

approximately as shown in chart Fig. 8.

FIG. 8 Hardness Range, Copper-Model BB-75

REPAIR AND REPLACEMENT

Cutaway view Fig. 9 clearly shows the working

parts of the various testers. Each tester has a seri-

al number stamped on the frame and this number

should be mentioned in all correspondence rela-

tive to repair. The model designation is stamped

before the serial number and this designation

must be observed when ordering parts or making

repairs.

Penetrators should be examined periodically for

wear with a magnifying glass. Penetrators showing

appreciable wear should be replaced with new

ones.

For purpose of clarication the following few points

are added:

The penetrator housings for all models are identical. The

dial indicators for all models are identical. All models em-

ploy single point penetrators but are different in contour

and should never be used inter-changeably. The load

springs for Models B and BB-75 are identical. The Model

B-75 uses a heavier spring. Return springs for all models

are identical.

310

Loading...

Loading...