Continued handle pressure causes the penetrator

to recede into the housing against the load of the

load spring.

“Bottom” is felt when the at lower end or face of

the housing rests against the material at which

point further pressure on the handles simply

squeezes the metal between the housing face and

the anvil. At this point the only load on the penetra-

tor is that of the load spring which is governed by

the setting of the load spring adjusting nut.

The dial indicator is tted to the upper end of

the penetrator housing and is actuated by the

movement of the penetrator. On metal of extreme

hardness the penetrator will recede into the hous-

ing until the tip is ush with the housing face. This

is the position of maximum penetrator travel and

is used for “zero” or full scale setting of the dial

indicator. It is obtained by completely compressing

the penetrator against the bare anvil. This will be

explained in detail later (see zero adjustment

page 5).

On metal of extreme softness the penetrator will

not recede into the housing at all, there will be no

movement of the penetrator and no reading will be

obtained on the dial indicator.

ZERO AND LOAD SPRING ADJUSTMENTS

There are only two adjustments on the Webster

®

Hardness Tester regardless of model; the zero

adjustment of the dial indicator and the load spring

adjustment. The zero adjust screw atop the dial

indicator case shown in Fig. 2 is adjusted at the

factory to take care of the accumulated toleranc-

es of a particular penetrator, housing and dial

indicator. It need never be adjusted unless one of

the reasons shown on page 5 is present and then

only if the indicating hand does not reach full scale

when the tester is operated against its bare anvil.

Care must be exercised in making the adjustment

in that the screw should not be turned until after

the handles are depressed fully. This prevents the

possibility of the indicating hand passing full scale,

striking the case and applying high torque to the

internal mechanism of the indicator.

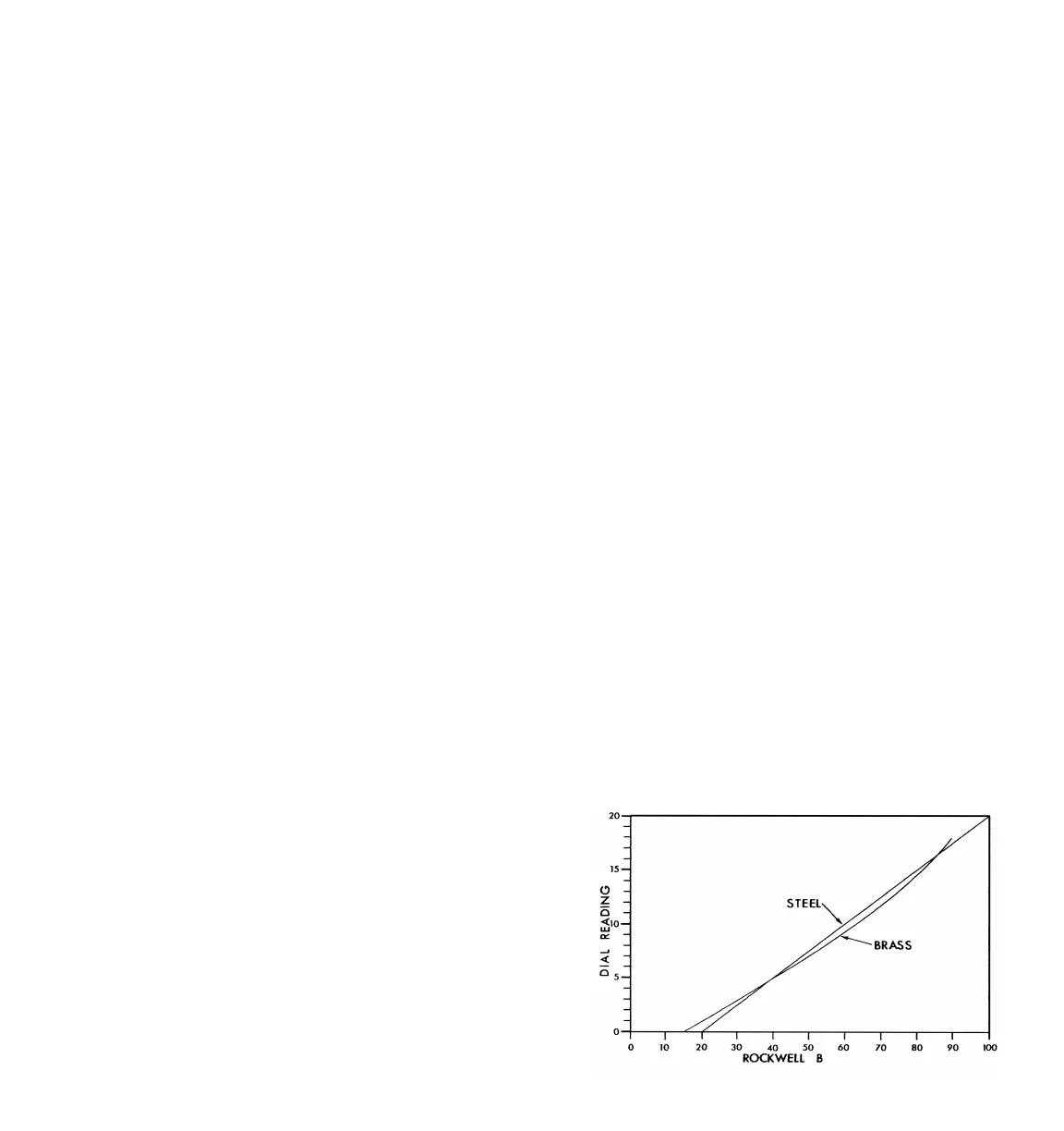

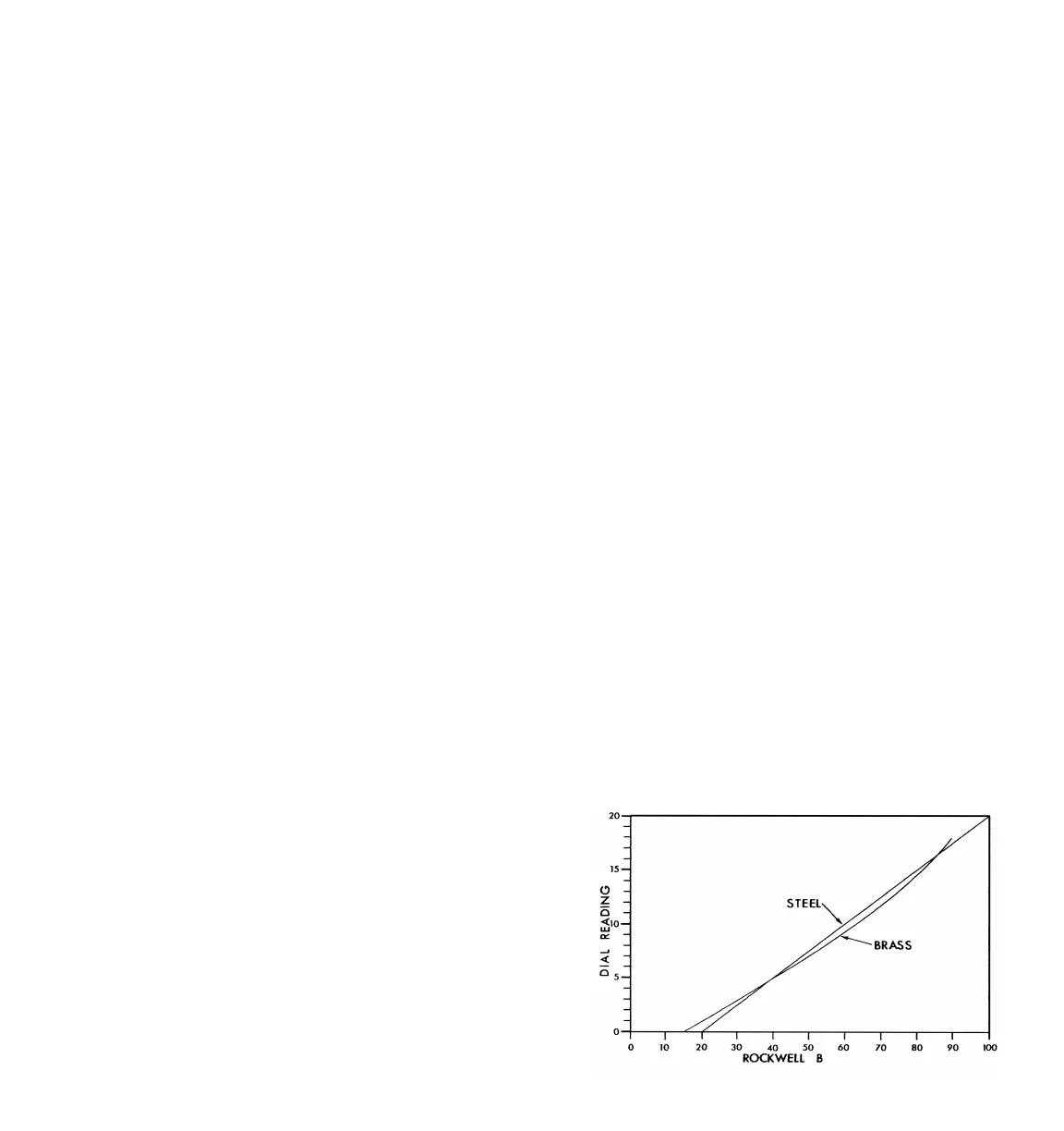

Graduations are 1 to 20. Hardness readings

obtained with the Model B-75 can be compared to

other standard hardness readings such as Rock-

well, etc.

As in all models the amount of load on the pen-

etrator is determined solely by the load spring

adjustment and is not affected by excess handle

pressure.

The Model B-75 uses a slightly heavier load spring

than the Models B and BB-75 but requires very

little additional pressure on the handles to operate.

The B-75 Tester is designed for use on brass and

mild steel and the 20 dial graduations will cover

the hardness range from annealed to full hard

brass. The B-75 Tester is more sensitive than the

Model B and therefore covers a smaller range of

hardness.

Each B-75 Tester is accompanied by a standard

sample stamped with the proper dial indicator

reading. This sample is to be used for routine

check to insure proper load spring adjustment.

Before making this check be sure the dial indicator

is in proper zero adjustment. (See par. 2, page 5)

If the reading taken on the standard sample does

not agree with the number stamped on it, load

spring adjustment must be changed to make the

readings agree.

With proper zero and load spring adjustment,

readings obtained on brass and mild steel samples

are approximately as shown in chart Fig. 7.

FIG. 7 Hardness Range, Brass--Model B-75

94

Loading...

Loading...