THE ZERO ADJUSTMENT

The method of making the zero adjustment of the

dial indicator is shown in Fig. 2.

With the tester operated against the bare anvil,

and handle pressure maintained, the zero adjust-

ing screw is slowly turned until the hand of the dial

indicator rests on the zero line of the dial face, which

is full scale reading. This zero line is at 20 on the B,

B-75 and BB-75 models. After this zero adjustment

has been properly made it should never be changed

except for one of the reasons listed below:

1. When a new penetrator is installed.

2. When the dial indicator is changed from one

penetrator to another.

3. When excessive wear has resulted in need for

a slight adjustment.

The operator can instantly check for correct zero

adjustment by operating against the bare anvil and

noting whether the hand comes to rest on the zero

line.

The zero adjustment should never be changed for

any other reason and it is extremely important that

the operator be warned of this fact. Never use the

zero adjustment to make the tester read correctly on

the sample but adjust the load spring, as described

below.

LOAD SPRING ADJUSTMENT

The load spring adjustment is the same for all mod-

els. The special wrench provided with each tester

is used as shown in Fig. 3 to vary the load on the

penetrator by applying more or less pressure on the

load spring. This is accomplished by rotating the

Fig 2 Zero adjustment screw ‘A” is indicated by arrow

SPECIAL INSTRUCTIONS FOR THE

WEBSTER

®

MODEL B-75 TESTER

The Model B-75 Tester has a single point pene-

trator with a different contour from the Model B

which can be identied from Fig. 5. The same dial

indicator is used for the B and B-75 Testers.

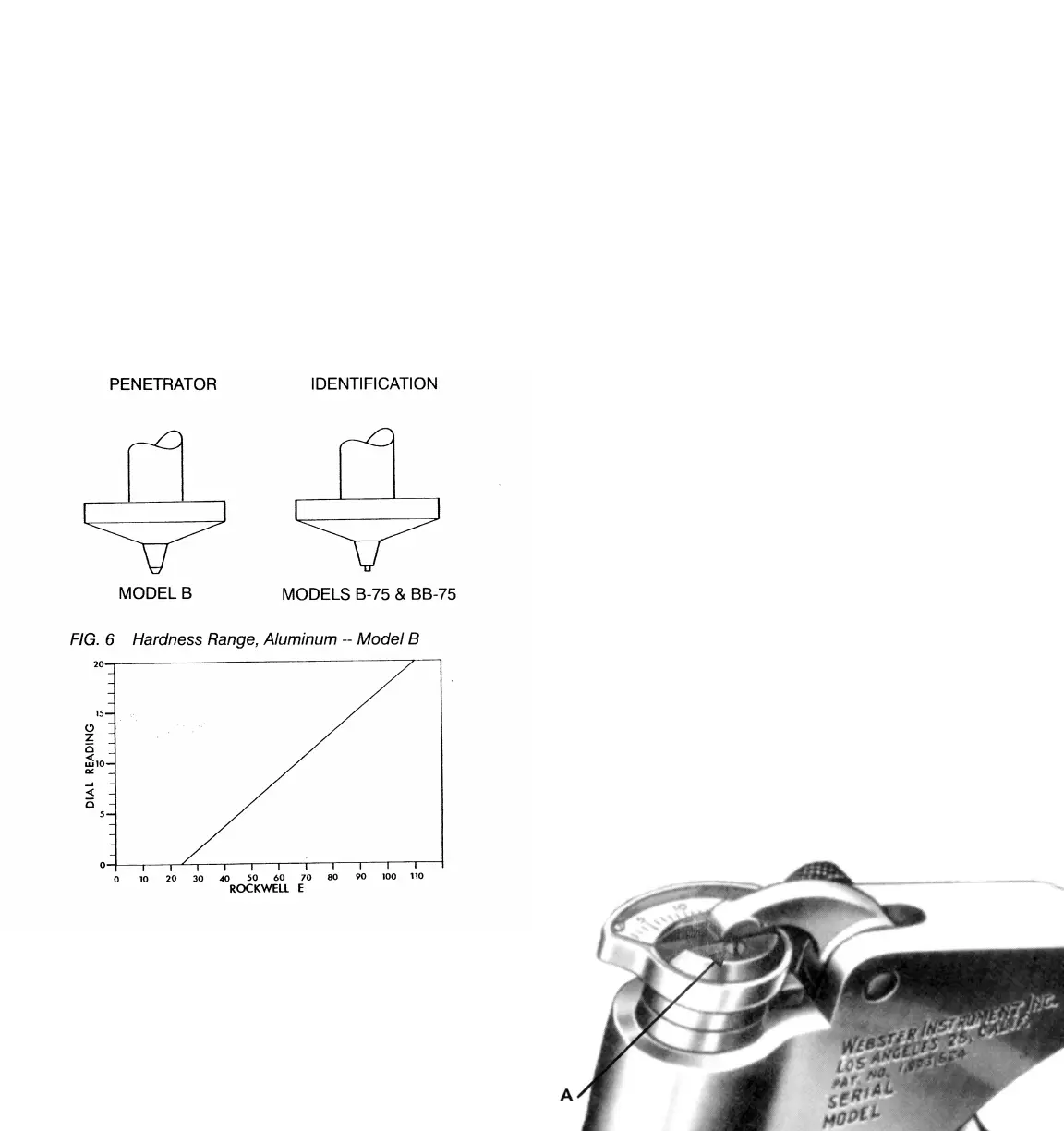

Each Model B Tester is accompanied by a stan-

dard sample stamped with the proper dial indica-

tor reading. This sample is to be used for routine

check to insure proper load spring adjustment.

Before making such check the dial indicator must

be in proper zero adjustment (see par. 2, page 5).

If the reading on the dial indicator does not agree

with the number stamped on the stand-ard sam-

ple, slight change must be made in load spring

adjustment until readings agree. When adjusted

properly the readings obtained on aluminum sam-

ples are approximately as shown in chart Fig. 6.

Fig. 5

58

Loading...

Loading...