adjustment nut. It is this load spring adjustment that

is used to standardize the reading to agree with that

of the standard sample furnished with all models. If

a reading taken on the standard sample does not

agree with the number stamped on it, the load spring

should be adjusted so that the reading obtained will

be the same as marked on the standard sample.

MAKING THE TEST

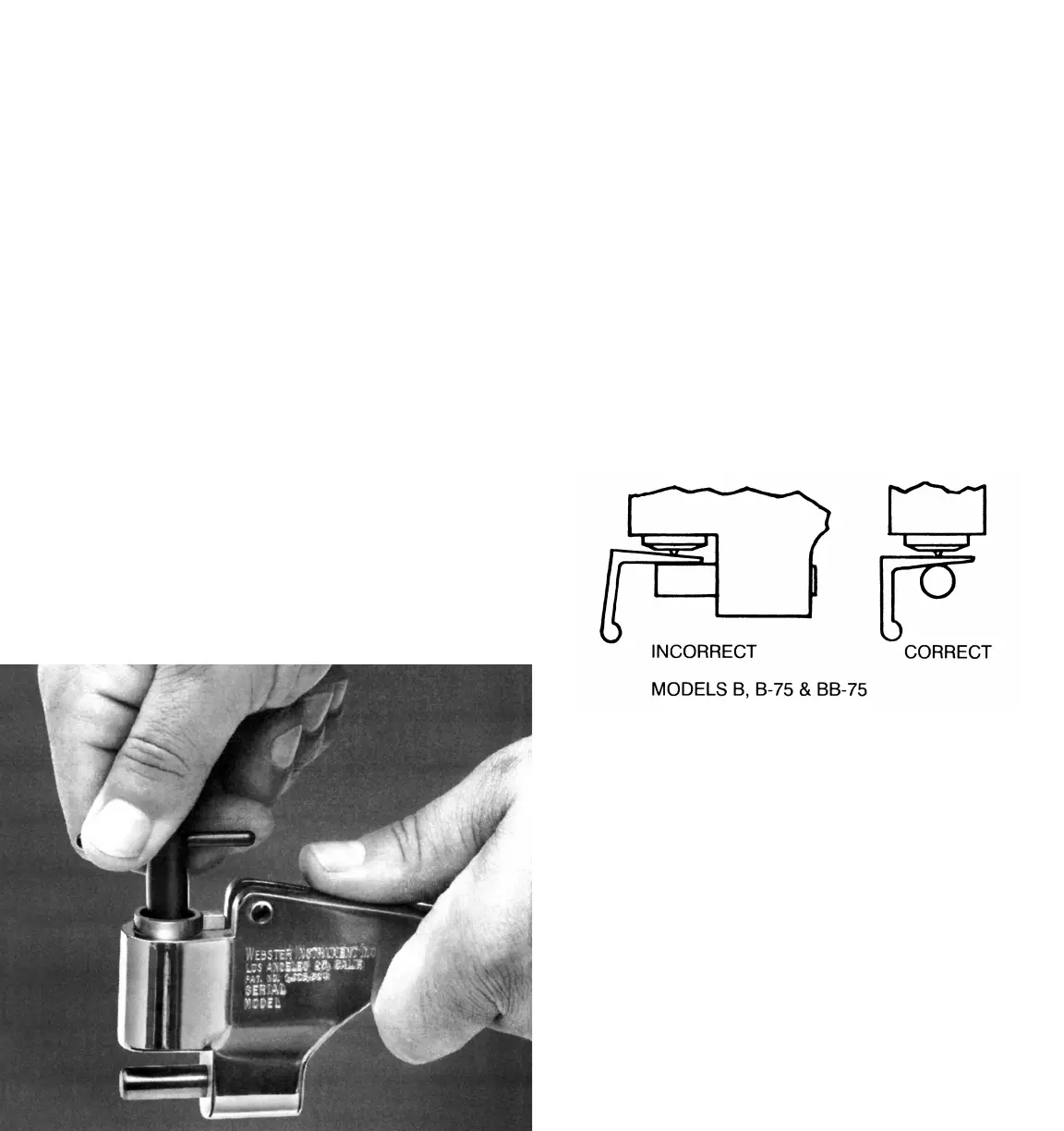

Each model is provided with a round anvil to facili-

tate testing of tubes, shapes or formed parts as well

as sheet and strip. In checking tapered sections

such as are found in some extrusions, the tester

should be applied in such a way that the anvil bears

along a line which is parallel to the surface in contact

with the penetrator. The right and wrong way of

checking such sections is shown in Fig. 4 page 7.

On at work such as sheet and strip no special

instruction is necessary as the metal to be tested is

simply inserted between the anvil and pene-trator.

Pressure is applied to the handles until “bottom” is

felt and the dial reading taken.

DISASSEMBLY

The entire tester can be taken apart for inspection

or repair by removing the pivot screw and

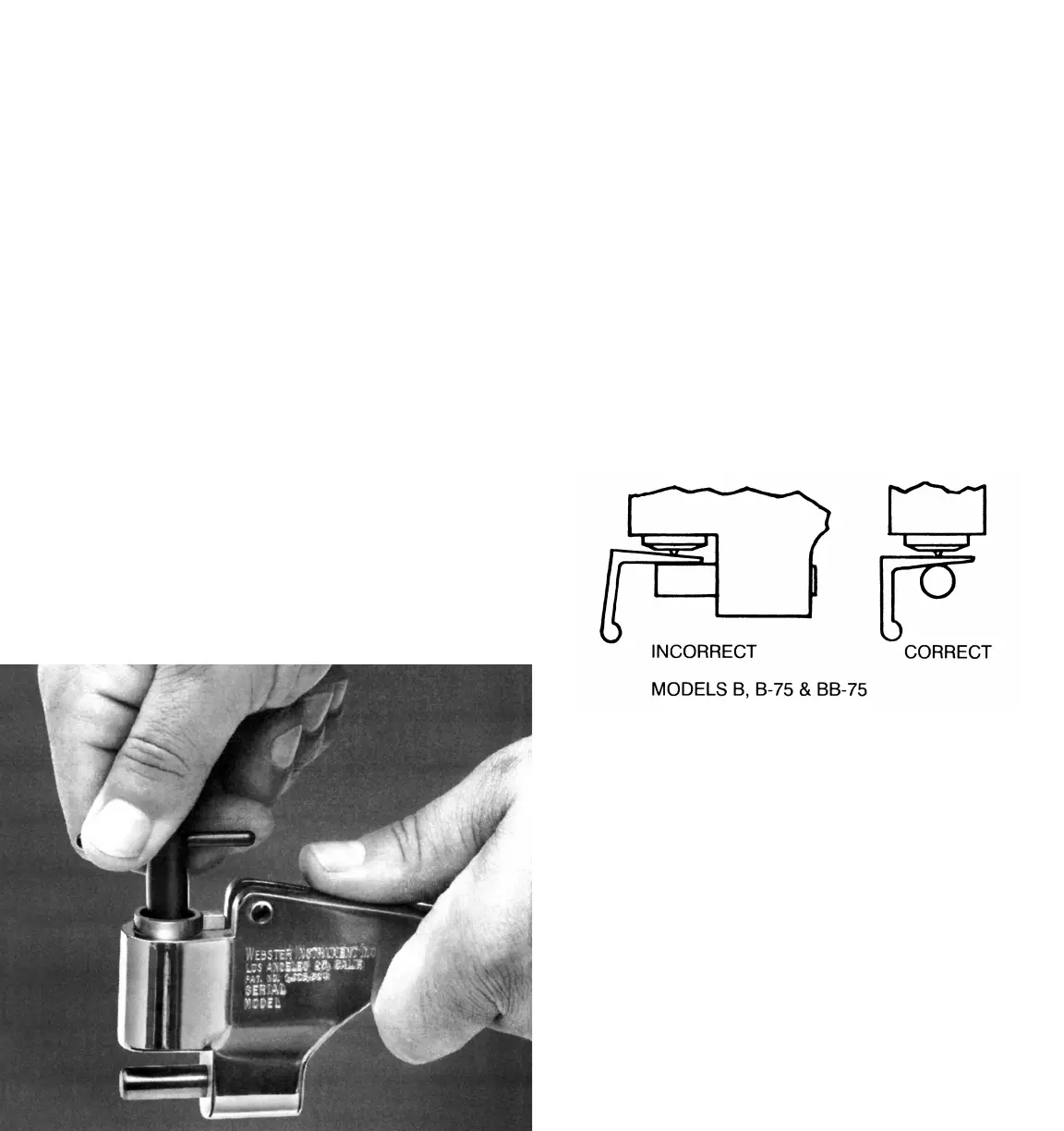

FIG. 3 Adjusting load on load spring

withdrawing the handle. The penetrator assem-

bly should be held downward with the thumb to

facilitate removal of the handle. After the handle is

removed the entire penetrator assembly is easily

lifted from the frame. The dial indicator may then

be lifted from the housing and the load spring ad-

justing nut backed off and removed with the spe-

cial wrench provided. This will relieve the load on

the spring and permit both spring and penetrator to

be removed. The return spring will be found in the

hole provided for it in the frame and the housing

key is easily detached from the housing.

The dial indicator should not be taken apart unless

an experienced instrument repair technician is

available. Dial indicators in need of repair should

be returned to the address shown in this manual to

insure that repair work will be properly done.

FIG. 4 Making the test

SPECIAL INSTRUCTIONS FOR

THE WEBSTER

®

MODEL B TESTER

The Model B Tester has a single point penetrator

which can be identied from Fig. 5. The dial

indicator is graduated I to 20 and the hardness

readings obtained can be compared to other

hardness readings such as Rockwell and Brinell.

As in all models the amount of load exerted on

the penetrator is determined solely by load spring

adjustment and is not affected by excess handle

pressure.

The handle pressure required to operate the

Model B Tester is the lightest of any of the

three models. This tester is designed for use on

aluminum and its alloys but may also be used for

other metals in that hardness range.

76

Loading...

Loading...