Î

Ensure that a controllable pneumatic source is available for the actuation in order to

maximize the service life of the front seal (Pos. 7) and to achieve an optimum seal-

ing for the application. The pilot pressure should be optimized to ensure a sealing at

the test piece, but without over-compressing the front seal. Excessive pilot pressure

can reduce the service life of the front seal.

Î

Always secure the WEH

®

Connector with a suitable fixturing device before adding

the test pressure.

Note: With vacuum application, a fixturing device can be dispensed with.

8�2 Connection

Connection of a TW01 connector / TW01 double

connector for non-threaded application

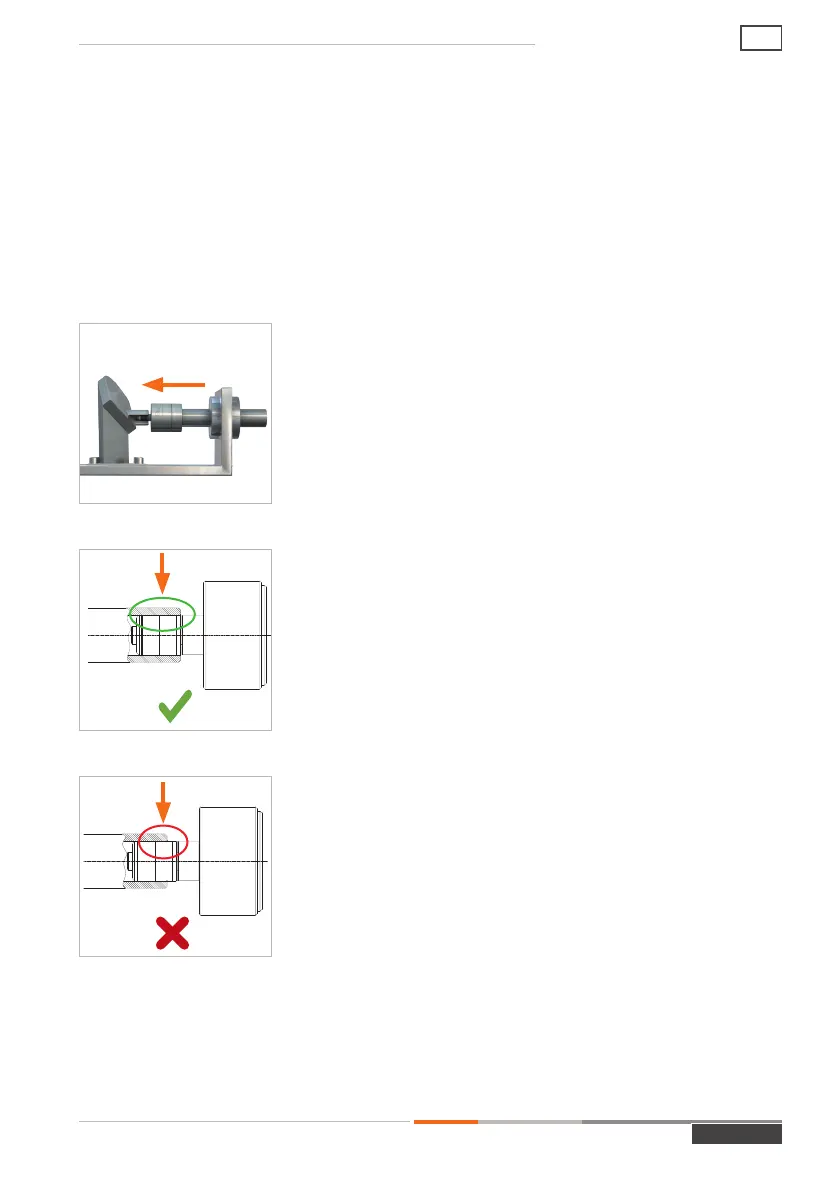

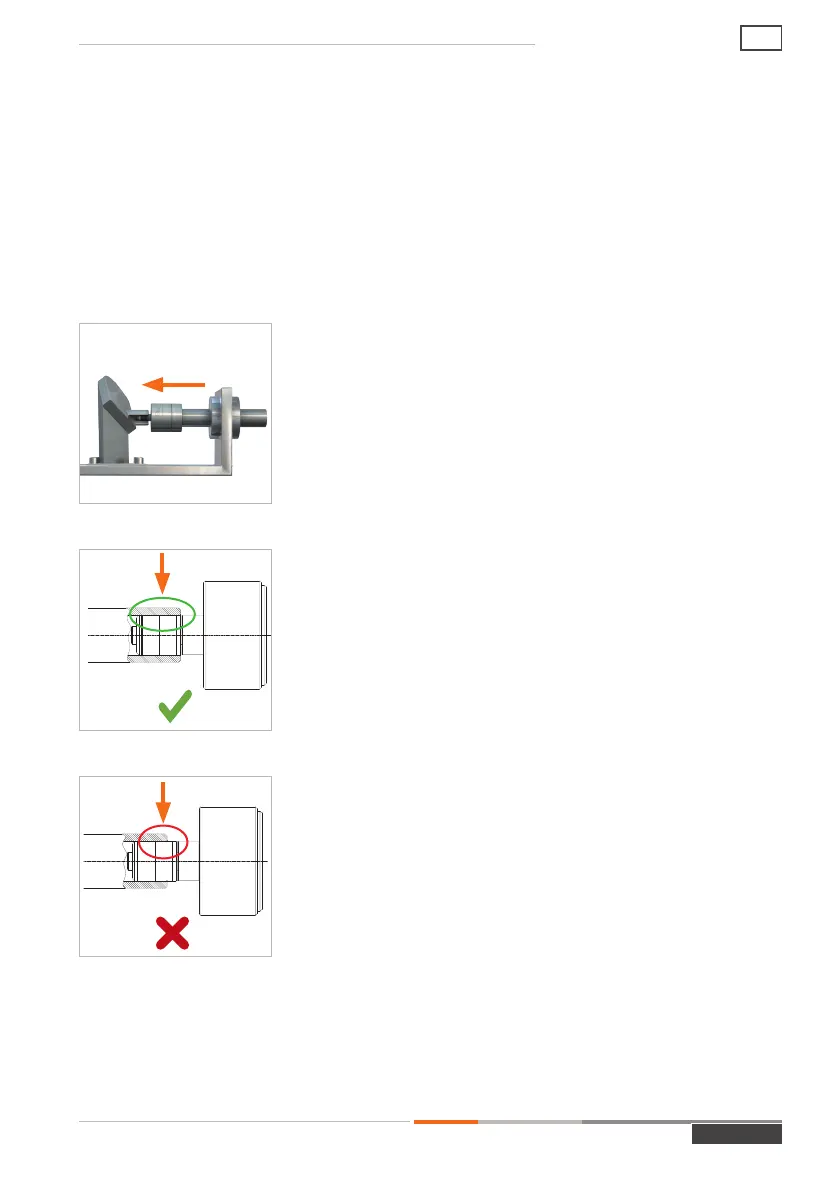

Î

Be careful to place the connector straight into the test

piece (Figure 1). The front seal (Pos. 7) must no longer be

visible (Figure 2 and Figure 3). Doing so will prevent any

damage to the front seal caused by any sharp edges on

the test piece and ensure a correct connection.

Note: Ensure that the connector is securely plugged into

the test piece using a mechanical connection before

proceeding.

Î

Apply pilot pressure to the connector. The elastic front seals

(Pos. 7) are compressed and the connector creates a pres-

sure-tight connection.

Note: Regulate the pilot pressure to the minimum required

for sealing under test conditions (pressure or vacuum). This

extends the service life of the seals.

- The connector is now connected pressure-tight to the test

piece.

Î

To start the testing procedure, apply pressure to media

inlet ‘B1’.

Figure 1

Figure 2

Figure 3

MD-10187-L51-R1.3.0-03

Page 21

Operating instructions

AE

Loading...

Loading...