Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine

40

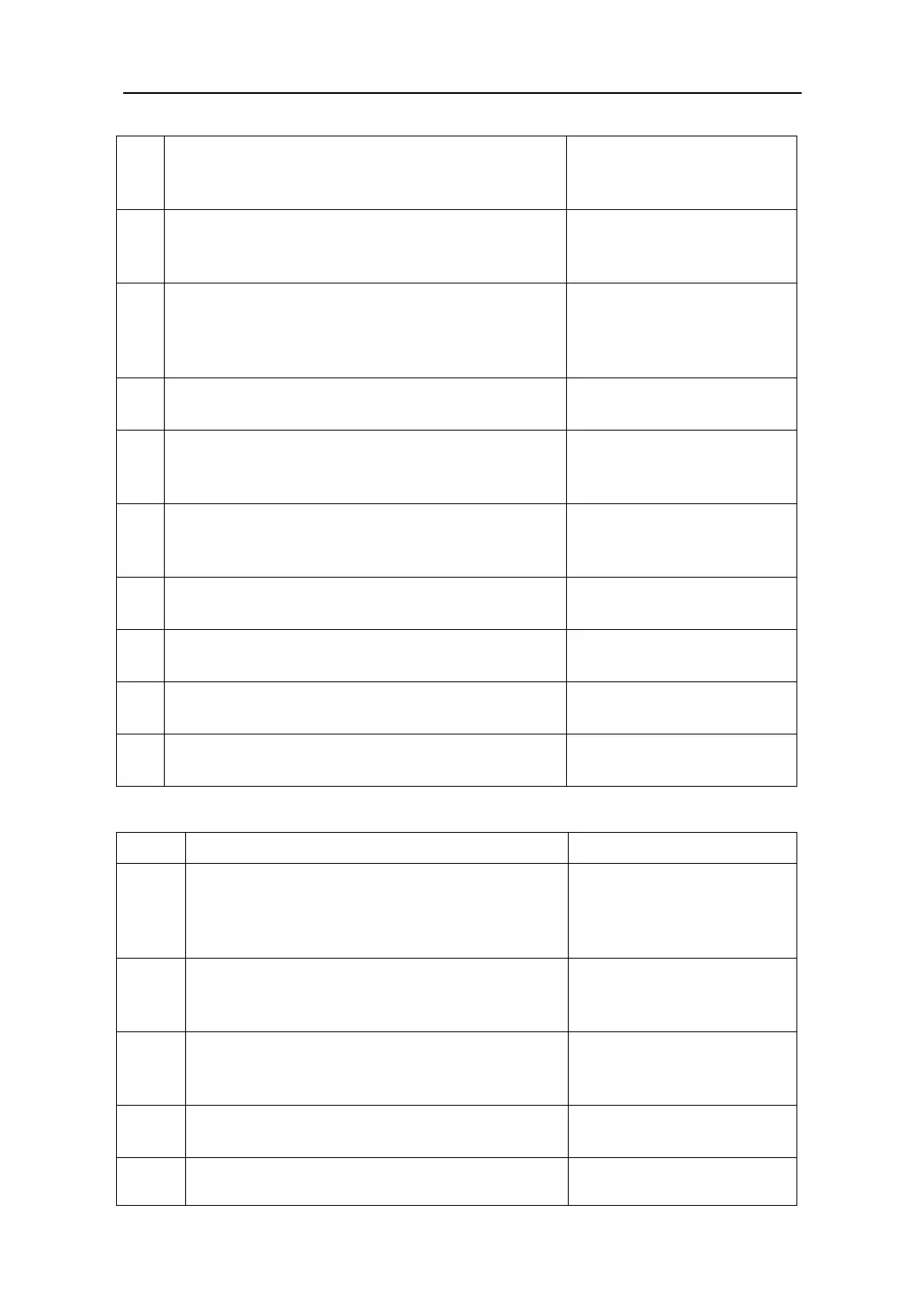

Each journal severely rubs with bearing bush on

crankshaft, making knocking noise along the

overall length of diesel engine.

Compression ratio is too high, causing rough

operation and large vibration.

The compression ratio

should be adjusted to

specification.

The clearance between the intake valve and exhaust

valve is undersize, or the exhaust or intake timing is

not correct, causing that the valve impacts the top of

piston.

Adjust valve clearance or

timing.

Individual cylinder does not work and diesel

engine vibration is aggravated.

Check the fuel system and

solve the failure.

The valve is fractured (the valve lock clip is

damaged, valve drops or the piston fractures,

causing sudden or strong knocking noise)

Immediately stop the

engine for inspection.

Air leaks from the cylinder head lining, making

howling.

Check the cylinder head nuts

for tightness or replace the

cylinder liner.

Wear of each gear is excessive, making knocking

noise.

The fixing bolts attaching to diesel engine is loose

or damaged, causing vibration aggravating.

Tighten or replace the bolts

Diesel engine is not coaxial to the connected work

device, aggravating the vibration.

Uneven foundation causes the deformation of

common base plate.

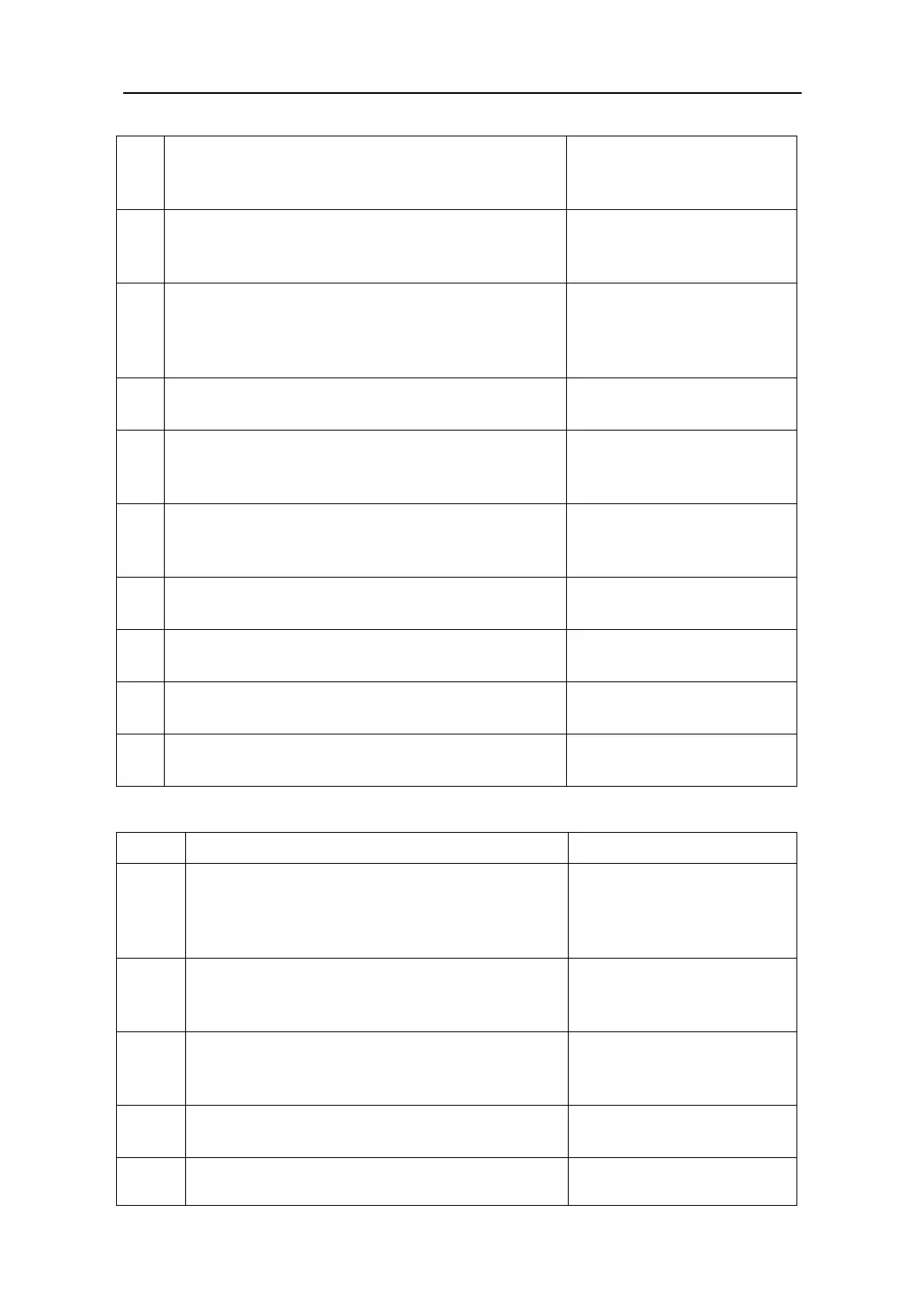

6.5 Diesel operation unsteady

The flyingweight of governor can not move

smoothly, or its clearance widens.

Check for stuck

phenomenon. Refer to the

actual practice for repair or

replacement.

The buffer circlip in governor is lack of

elasticity or fractured, making the adjusting

rack shake or unsteady.

Diesel engine speed is too low; with engine

idling at mid speed, two-purpose governor can’t

activate automatically.

The diesel engine load varies frequently.

Check the load output

state.

Some cylinder intermittently fires, making the

fuel be accumulated in cylinder and accordingly

Loading...

Loading...