Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine

41

lead to knocking of cylinder.

The fuel injectors have different amount of fuel

distribution and injection time.

Air enters the fuel system.

Air enters the fuel system

Check the fuel system and

degassing it.

Timing gear plays forward/backward.

Check each gear for

tightness.

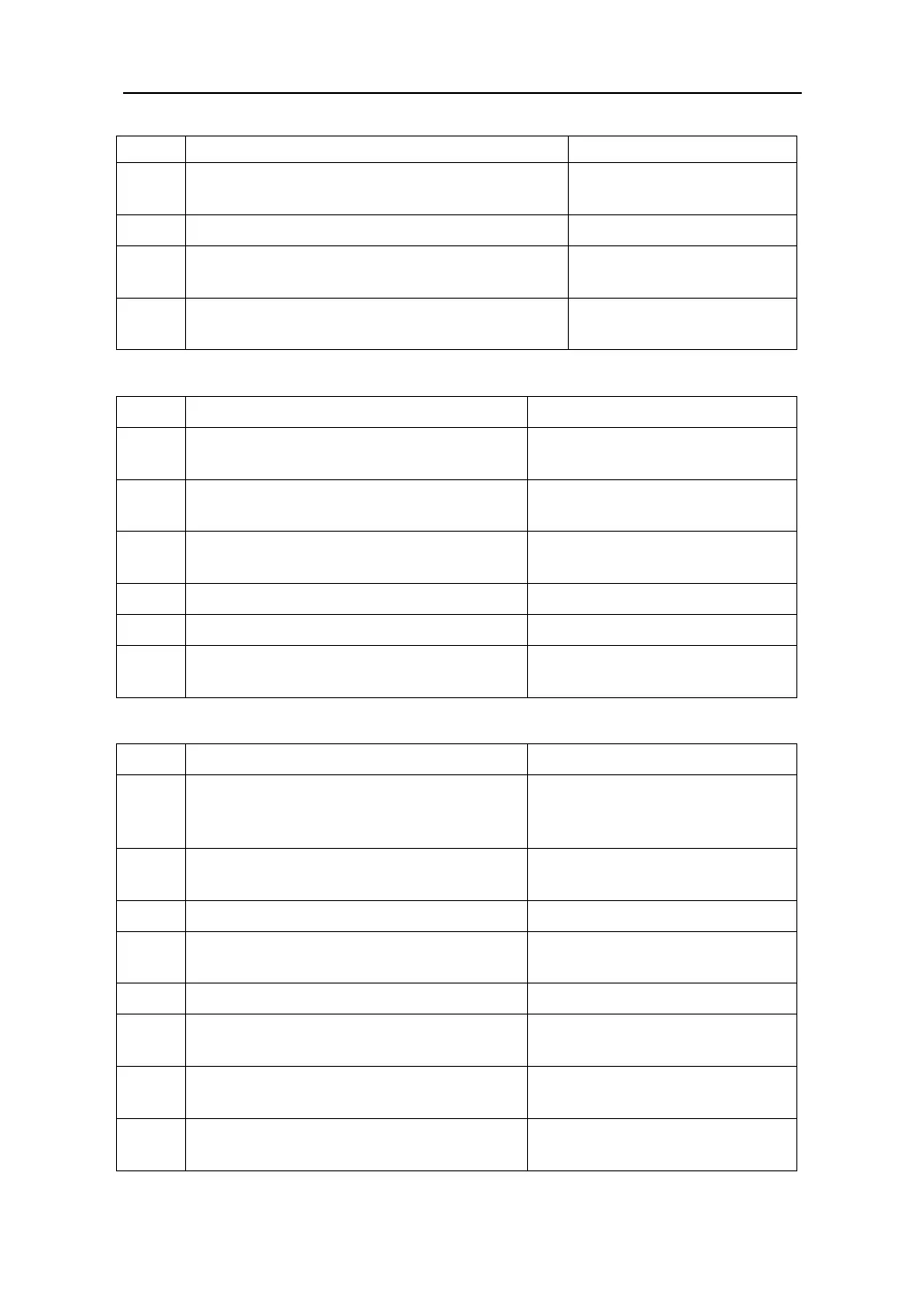

6.6 Water pump can’t absorb water or pump enough water

Air enters the water pump or suction pipe.

Fill them with water to drain the

air.

water pipe is clogged or froze (cold

season)

Clean or fill it with hot water or

antifreeze.

Seals of coolant pump are damaged or

leaked.

Water pump belt is too loose.

Water pump has too much scale.

Water pump has excessive suction head.

Refer to the specifications to

install the water pump.

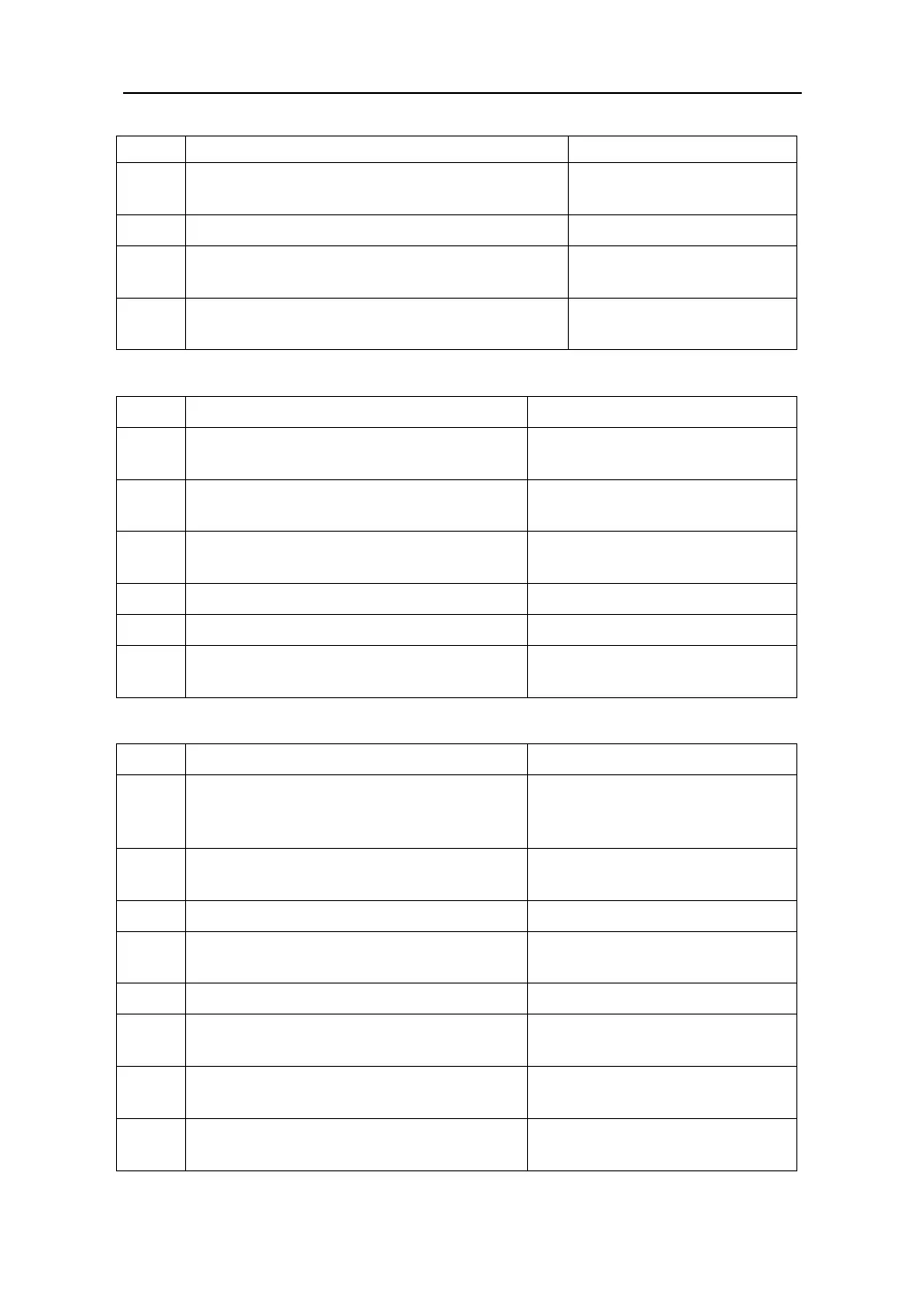

6.7 Too low oil pressure

Oil quality is poor (because as the diesel

engine is running, the oil pressure

gradually drops).

Refer to the specifications to

select the oil.

Diesel engine overheats or the oil is

thinned.

Refer to the section 6.8 in this

chapter.

Oil pipe joint is loosened or air enters oil

pipeline.

Diesel fuel is mixed in the oil.

Pressure-regulating valve spring is

fractured.

Oil in the oil tank drop or the suction head

of oil pump is excessive big.

Refill the oil, or reinstall the oil

pump or oil tank.

The clearance between the connecting rod

bearing and main bearing is widened.

Loading...

Loading...