Epsilon Echos +

7

DESCRIPTION FOR FUNCTIONS AND AC-

CESSORIES

Condensation/evaporation control with fan rev. regula-

tor (standard)

The microprocessor control monitors all the operating para-

meters of the unit and constantly regulates the speed of the

fans by means of a rev. regulator to optimize the operating

conditions and efficiency of the unit.

As a result, the unit also runs much more quietly. The con-

trol device typically modulates the speed of the fans at night

and during half-season. The machine therefore minimizes fan

speed and the level of noise at every given opportunity.

Remote ON/OFF from digital input (standard)

All the units come with this function as standard. It consists of

a remote contact for turning the machine on and off by means

of a signal that can be taken inside the building by a Building

Management System (BMS).

Summer/winter selection from digital input (standard)

This function is standard for all heat pumps. When you switch

on the unit, you need to set either heat pump or chiller mode.

The remote contact makes it possible to change the work

mode even inside the building and without direct access to the

microprocessor control.

Electronic thermostatic valve (standard)

This accessory is recommended for units that have to tolerate

highly variable refrigeration load or variable working condi-

tions, for example when managing both air conditioning and

the production of water at a high temperature. Use of the

electronic thermostatic valve makes it possible to:

• maximise the heat exchange to the evaporator

• minimise time of response to variations in load and working

conditions

• optimise the regulation of over-heating

• guarantee maximum energy efficiency

Standard also for /LE and /LE/HP units.

Brine Kit

This accessory is required when the outlet temperature of the

evaporator is within the range of +3°C and -8°C. It consists of

extra thermal insulation of the exchanger and tubes, specific

calibration of the low pressure gauges and anti-freeze alarm,

and testing of the size of the mechanical thermostatic valve.

Filling system with manometer

This accessory enables automatic loading of the hydraulic sys-

tem and correct adjustment of the working pressure shown on

the manometer, and maintains the level of pressure in the hy-

draulic system refilling the system with water when necessary.

Anti-freeze heater

These heaters are fitted on the exchanger, pump and tank

(depending on machine configuration) to prevent damage to

the hydraulic components due to the formation of ice when

the machine is out of use.

The control device monitors the outlet probe of the exchanger

(even when the unit is in standby) and when this registers

a water temperature of 5°C or less (or 2°C below the set

point temperature, with a differential of 1°C) it triggers the

antifreeze heater. When the temperature of the outlet water

reaches 4°C (or 3°C below the set-point), it also triggers the

anti-freeze alarm that stops the compressor without however

disabling the heaters.

Integration electrical heater

This is an electric heater installed in the inertia storage tank of

the ST 1PS module that helps the heat pump reach the setpoint

temperature when the power supplied by the machine is not

sufficient for the load.

The accessory is available only for version /HP /ST 1PS

RS485 serial interface

The increasing use of home automation and BMS (Building

Management System) systems has led to the need for a single

comprehensive supervision system for all the various compo-

nents. The unit can, therefore, be equipped with a serial board

that permits perfect integration of the machine within the

”building-system” with MODBUS or CAREL communication

protocols

Remote user terminal

Intended for a professional user, this accessory consists of a

faithful reproduction of the control panel at which you can

fully configure the unit and view its parameters on the display

screen. The insertion of passwords is required to access the

parameters at different levels.

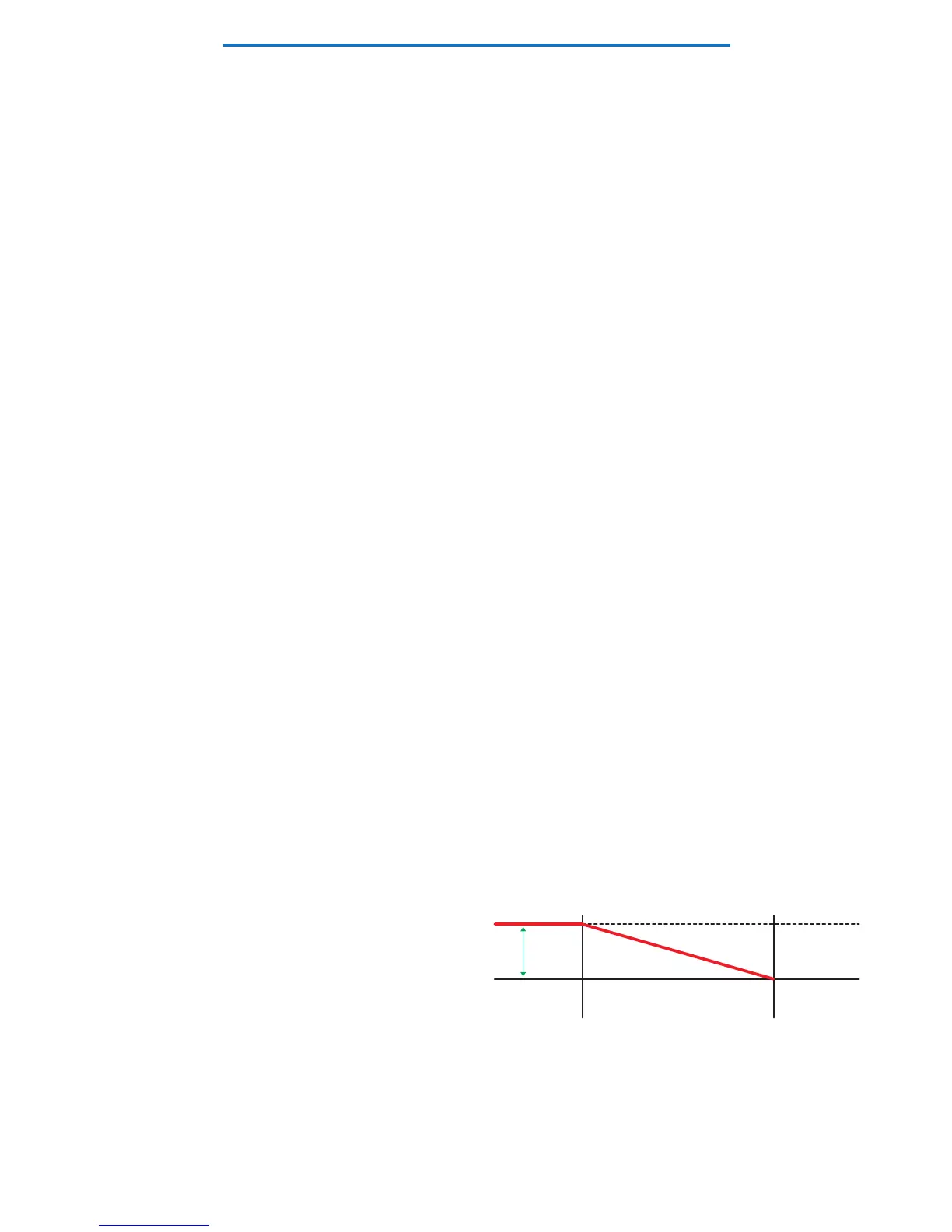

Compensation of the set-point depending on the exter-

nal air temperature

Units equipped with this microprocessor control accessory can

compensate the set point according to external air temperatu-

re. The compensation can be positive or negative: with positive

compensation, the set-point increases in relation to the exter-

nal air temperature, while with negative compensation the

set-point decreases in relation to the external air temperature.

Only winter set point can be compensated.

Unless specified otherwise in the order, standard programming

involves negative compensation as shown in the diagrams

below. All the settings can be modified directly by the control

system.

Loading...

Loading...