TROUBLESHOOTING GUIDE

Troubleshooting

Always be sure that anytime you are working with your marker you are in a safe environment.

A safe environment is an area where you and every one within 200 yards is wearing paintball

approved safety goggles and equipment. Also be sure to empty all paintballs and exhaust all

air from the marker before storing the marker in a secure locked place.

Note: A qualied technician should make all repairs and adjustments.

Do not attempt to perform any factory-only repairs. Call WGP for any service needed on your

marker. Any damage caused by improper adjustments is not covered by the warranty.

1. Marker won’t re properly or has low velocity after removing and replacing bolt. Bolt

installed upside down. Remove bolt. Reinstall after rotating 180 degrees. The hole side should

be facing down.

2. Marker will not re when trigger is pulled.

a. Marker OFF, turn marker ON

b. Battery low, replace battery

c. Gas source pressure low or tank empty. Fill tank.

d. Ensure inline HP regulator is adjusted to correct operating pressure.

e. LPR low, adjust higher.

3. Marker will not cock or cocks every other time or less

a. Pressure too low. Fill bottle or adjust regulator.

b. LPR regulator pressure set too low.

c. Timing lug out of adjustment.

d. Velocity adjustment set too high.

e. Side cock block or cocking rod adjustment incorrect.

f. Eyes may be OFF, turn marker eyes ON.

g. Timing on PCBA adjusted to far out, reset PCBA to factory settings.

4. Chops paintballs.

a. Break beam eyes blocked, check eyes.

b. Bad eyes, replace.

c. Loader is not feeding fast enough.

d. Ensure bolt clears breech fully. See side cock block and pump rod adjustment.

e. Paint is soft or swelled. Ensure that paint is not too large for barrel.

f. Old bad paint, replace paint.

g. Check loader and breech for foreign matter.

5. Leaking between tank valve and marker Bottom line Air Receiver.

a. Bad valve O-ring. Replace valve O-ring. This is the external O-ring at the top of the valve.

6. Low velocity

a. Gas source pressure too low or tank empty. Fill tank.

b. Improper IVG adjustment. Adjust velocity.

c. Regulator pressure too low or high. See sweet spotting the regulator section.

d. Check gas source. Make sure input pressure to marker is consistent.

e. Paint rolling down the barrel. Paint too small.

f. Bolt upside down.

g. Timing on PCBA adjusted to far out, reset PCBA to factory settings.

7. Gas leaks down the barrel

a. Hammer is resting on the valve stem. When you gas up the gun, always make sure to cock

it rst. When the hammer is forward, it will push the valve slightly, and hold it open. This can

cause either a massive barrel leak if the input pressure doesn’t force the valve closed, or a brief

spurt of air as the pressure closes the valve.

b. Cup seal not seated correctly. In a safe environment, oil your marker and re it a few times

to help seat the valve. Fire marker a couple of time with out balls. The cup seal may reseal af-

ter a couple of shots. If you still hear excess air escaping from the marker, call WGP for service.

c. Cup seal dried out. Put 5-6 drops of paintball gun oil in the ASA, and shoot the gun until you

can hold a paper towel over the breach, shoot, and it stays clean.

d. HP regulator is not set up correctly.

e. Bad cup seal, a replacement may be required.

f. Bad valve o-ring. Remove and replace exhaust valve. This should only be done with special-

ized tools. Contact WGP.

8. Marker cycles slowly

a. Low pressure from regulator. Adjust.

b. Leaky ram. Replace or rebuild the ram.

c. Oil and re-lube the marker

d. Low tank pressure.

e. LPR set too low, adjust up.

f. Program speed limited, reset program to factory settings.

F.A.Q.

Q) How do I safely maintain my WGP Autococker® marker?

A) Safely maintaining your marker is simple and easy. You need only clean and oil your

marker to keep it up and running.

Q) How do I oil my marker?

A) You only need to lubricate your marker after every 4 to 5 days of play. To oil your maker

you rst, in a safe environment, remove your loader, then re all excess paintballs out of the

marker. Next remove your tank and re all excess air from the marker. Now remove your bar-

rel. Next drop 3 to 4 drops of either 3 in 1 oil or any other approved paintball marker oil into

the air receiver and safely re the marker 10-15 times. This will distribute the oil throughout

the internals of the marker. At this time you can also lubricate your bolt 0-rings. Be sure

that the hole in between the 2 O-rings on your bolt is always facing down. Factory approved

lubricants: Petroleum jelly, 3 in 1 oil and lithium grease.

Q) How do I safely clean my marker?

A)To clean your marker you rst nd a safe environment then remove your loader, then re

all excess paintballs out of the marker. Next remove your tank and re all excess air from the

marker. Now remove your barrel, then lightly spray down marker with a 50-50 mix of rubbing

alcohol and water and then wipe it down with a clean cloth.

Q) Does WGP recommend C02 or compressed air on the ASR?

A) WGP recommends compressed air. CO2 is not recommend since there is a possibility of over

pressurizing and freezing the marker.

Q) Sometimes when I air up my marker, I hear air coming out of the barrel. What causes that?

A) Before you air up your marker always be sure to cock the marker rst, this will take the

pressure off of the valve and stop the air from escaping, if you still hear air escaping try oiling

and ring the marker a few times in a safe environment to seat the valve. If you continue to

hear air escaping, call WGP for service. It is not recommended to adjust or remove the hammer

or hammer lug without proper training. See trouble shooting tips.

Q) What is timing? And do I need to adjust it?

A) Timing is the length of time between when your marker res and when it starts to re-cock.

Your marker comes timed from the factory and should not need to be adjusted. It is not recom-

mended to adjust or remove the hammer or hammer lug without proper training.

Q) I broke a paintball in my marker. How do I clean it?

A) To clean broken paintball out of your marker you will rst remove your loader, next your

tank be sure to re all excess paintballs and air from your marker. Next remove your barrel

and then your bolt. Using a squeegee or battle swab, run it through the same chamber you

pulled the bolt from, then run it through the barrel. Reinstall the bolt. Be sure that the hole in

between the 2 o-rings on your bolt between the 2 o-rings is facing down and you’re ready to go.

Q) I’ve removed my bolt and replaced it, and my velocity has dropped. What is the problem?

A) Any time your remove the bolt from your marker, you must always be sure that the hole in

between the 2 O-rings on your bolt is always facing down before reinstallation. This is common

problem that could directly affect the velocity of your marker.

Q) What is the reason to have different barrel sizes?

A) The reason for using different barrel sizes is, paintballs are different sizes due to freshness,

weather and other factors. By having different barrel sizes your will be able to match your

paint to your barrel to get the best accuracy and consistency out of your marker.

Q) I have a question that is not on this list. What do I do?

A) If you have more questions and did not nd the answers here, Please contact WGP directly.

Or visit www.worr.com

WARRANTY INFORMATION

WARRANTY: LIMITED 90 DAY WARRANTY

(ORIGINAL PURCHASE RECEIPT REQUIRED)

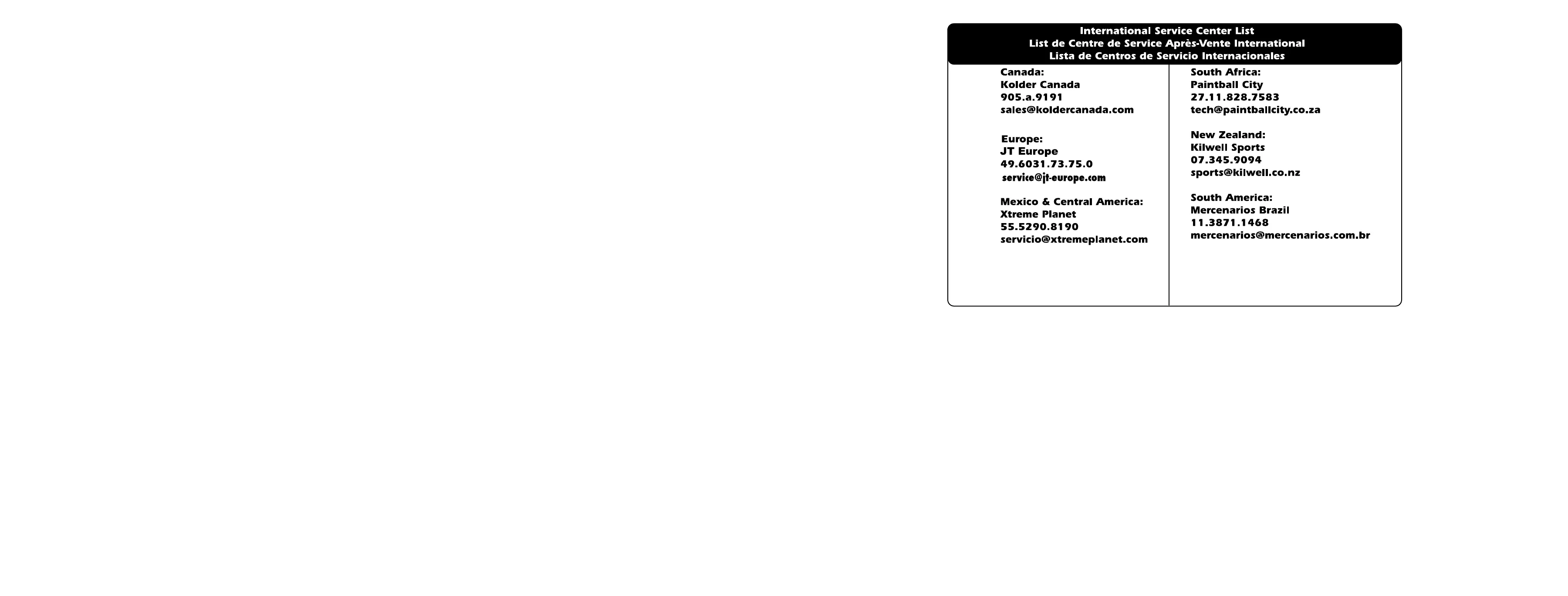

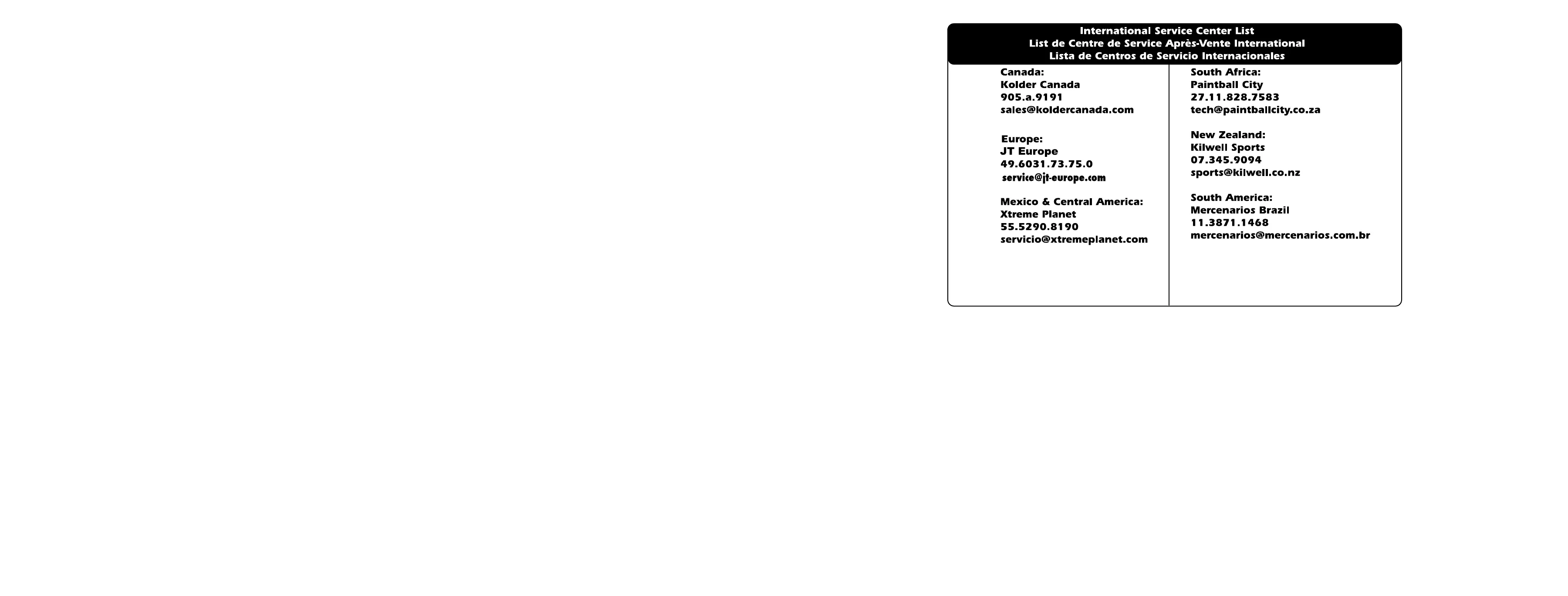

For 90 days from date of purchase, Worr Games® will repair or replace this marker free of charge if defective in material or workmanship. This warranty gives you specic legal

rights. You may also have other rights which may vary from state to state. Service is available from authorized Worr Games® Service Centers. A list of these is available at Worr

Games® website at www.worr.com or by calling Worr Games® at 1.800.755.5061 These Service Centers gener-ally offer the quickest service.

If you would rather return your marker to Worr Games® please call customer service at 1.800.755.5061 for return authorization number and shipping address. (Authorization

number must be visible on outside of ship-ping package to be accepted.)

Do not return any products via non-trackable services such as regular mail or parcel post. Such products may become lost and Worr Games® will not be responsible for replacement.

PAINTBALL MARKERS OUT-OF-WARRANTY

Authorized Service Centers will gladly repair any markers out of warranty for a nominal charge to cover parts and labor. Repairs made by Service Centers will usually be faster and

less expensive than those sent back to the factory. Go to www.worr.com for service center locations near you. Prior to shipping out of warranty markers, you must rst call customer

service at 1.800.755.5061 for return authorization number and shipping address. (Authorization number must be visible on outside of shipping package to be accepted.) Any out of

warranty Marker returned to Worr Games® must be shipped prepaid and include the repair fee. Please call the Customer Service number for current repair fees. Worr Games® will

repair or replace the marker with a reconditioned unit of the same model. If payment is not included, you will be billed for the repair fee plus a $4.00 invoicing fee. Upon receipt of

payment, the marker or its replace-ment will be shipped to you. In the event that the marker includes no means of contacting the sender or no payment for repairs is received within

60 days of billing, the ownership of the marker will be forfeited and it will be disposed of at the discretion of Worr Games® Inc.

Loading...

Loading...