- whenever you leave or transport the Fruit Crusher;

-before clearing a blockage;

-before checking, cleaning or working on the Fruit Crusher;

-after striking a foreign object. Inspect the Fruit Crusher for damage and make repairs as

necessary;

-if the Fruit Crusher starts to vibrate abnormally or makes any unusual noise (check

immediately).

If the cutting mechanism strikes any foreign objects or if the Fruit Crusher should start

making any unusual noise or vibration,

31) Inspect for damage.

2) Replace or repair any damaged parts.

3) Check for and tighten any loose parts.

Do not attempt to repair the Fruit Crusher unless you are competent to do so.

Do not allow processed material to build up in the discharge area; this may prevent

proper discharge and can result in kickback of material through the feed opening.

Electric Safety

Connect the mains lead to a standard 230 volt (50Hz) electrical supply via a 13 amp

BS1363 plug fitted with a 13 amp fuse.

The severed plug must be disposed of to avoid a possible shock hazard, and should

never be inserted into a 13A socket elsewhere.

Your Fruit Crusher is double insulated for safety and requires no earth connection.

The operating voltage is 230V ac, 50Hz.

Extension cable:

The type of cable used must be 2 core double insulated with a cross section of 3 x

1.0mm2.

In case of uncertainty please consult an electrician or your local dealer.

Operation

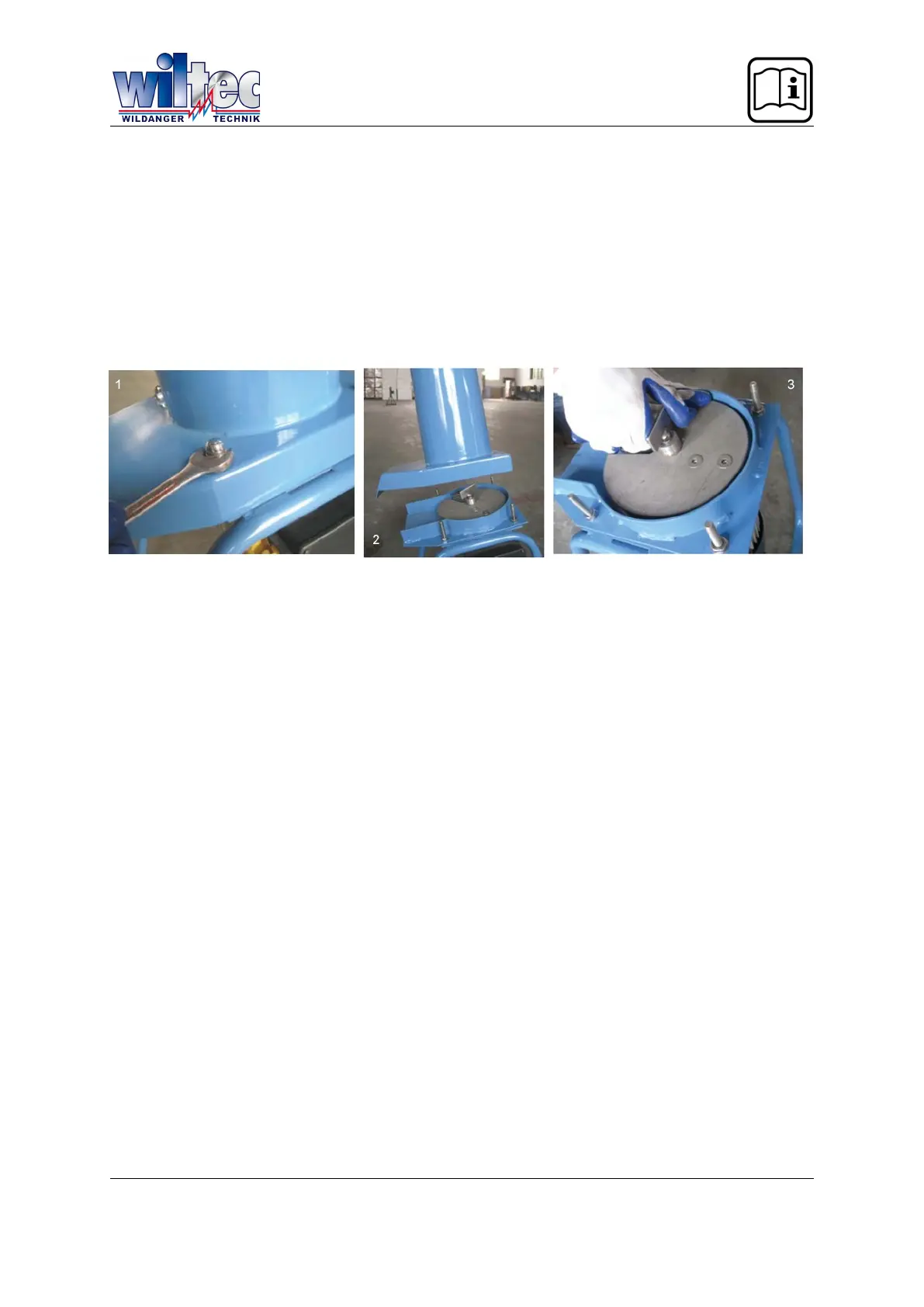

With the machine standing on firm level ground, standing on a board if necessary, plug the

machine into the mains supply, via a residual current device (RCD).

Place a collecting container such as barrel or box below the outlet port to collect crushed

fruit.

Then start the machine by pressing the ON/OFF rocker switch shown below, to ON.

When the machine is running at full speed, proceed to feed material into the hopper, DO

NOT force it.

Please start machine FIRSTLY, and feed fruit after machine start running. It’s

very IMPORTANT!

The cutter blades will pull the material into the machine.

NEVER push material into the hopper with your hands.

The material must be of a size to easily enter the holes in the hopper.

IMPORTANT!

Should the machine become clogged and stop delivering chippings, switch OFF and

immediately and disconnect from the mains supply.

Using industrial quality gloves remove any material in the chute. Take great care to avoid

contact with the cutter blades- use a stick where necessary.

© by WilTec Wildanger Technik GmbH Seite 12

http://www.WilTec.de

http://www.aoyue.eu

http://www.teichtip.de

Loading...

Loading...