Ensure the cover is properly secured before plugging into the mains supply and restarting.

Clean & Maintenance

Maintenance is limited to ensuring the machine is clean and free of corrosion by the malic

4acid found in juice.

Clean

1˅Remove the bolts(2) from Main Body(1).

2) Discharge the Main body(1) and clean it.

3) Remove the Rotated Plate fixed the cutter plate and take the cutter plate(10) from Base

Plate (15) and get cleanning.

Taking great care to avoid contact with the cutting blades to cause hurting when

cleaning.

ALWAYS ensure the machine is switched OFF and disconnected from the mains supply

before carrying out any cleaning operations. Reassemble the Fruit Crusher in reverse order.

Maintenance

Dry the machine after cleaning to prevent rusting.

Lightly edible antirust oil all surfaces to prevent rusting if long time no

using.

5Product Specification

Motor 230V 50Hz Crushing Capacity 600 kg apples (approx) per hour

Power 1,100 Watt Net weight 25 kgs

Electromotor speed 2,800 rpm Gross Weight 28 kgs

IP rate IP 44 Dimensions 1290 x 450 x 380 mm

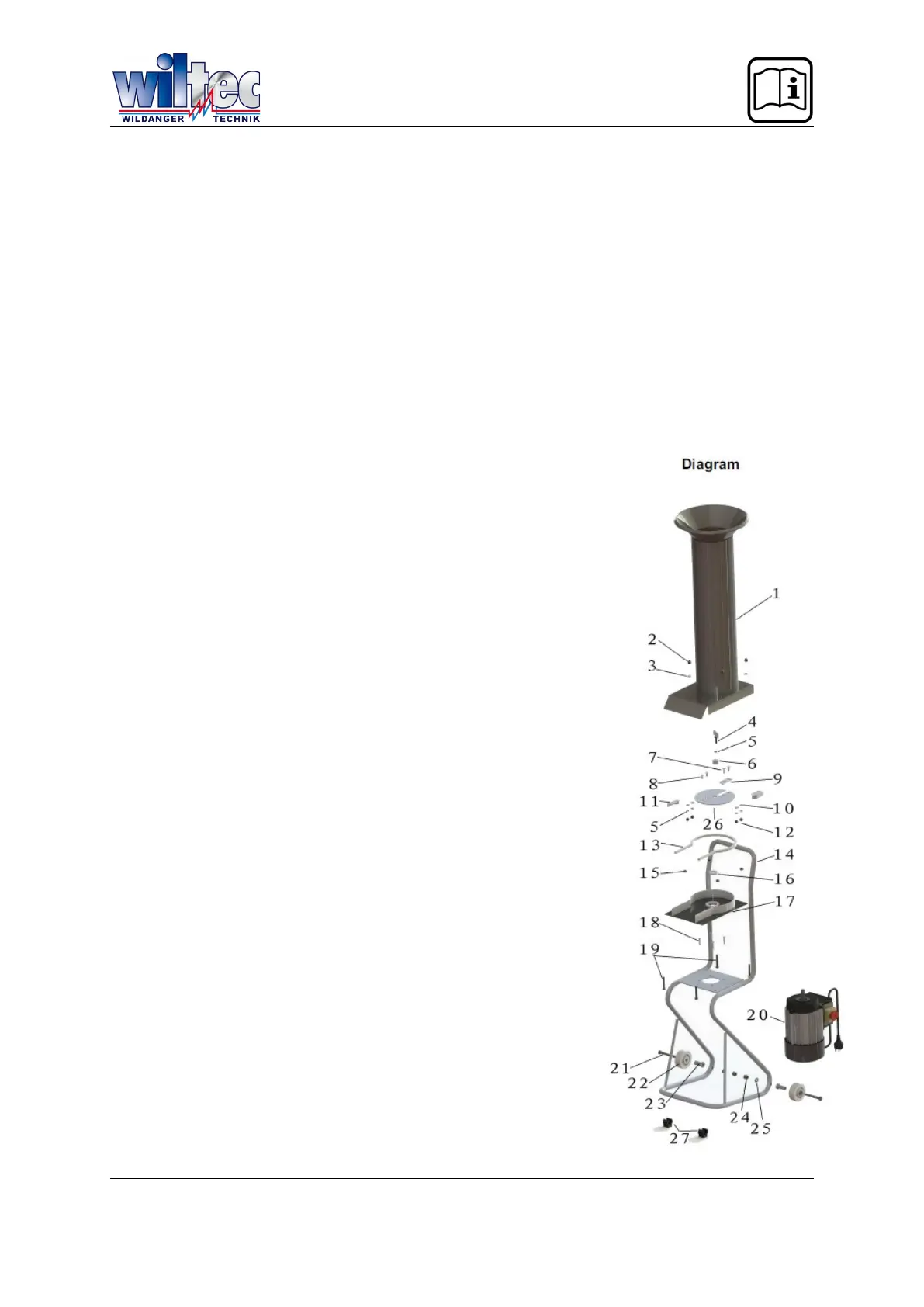

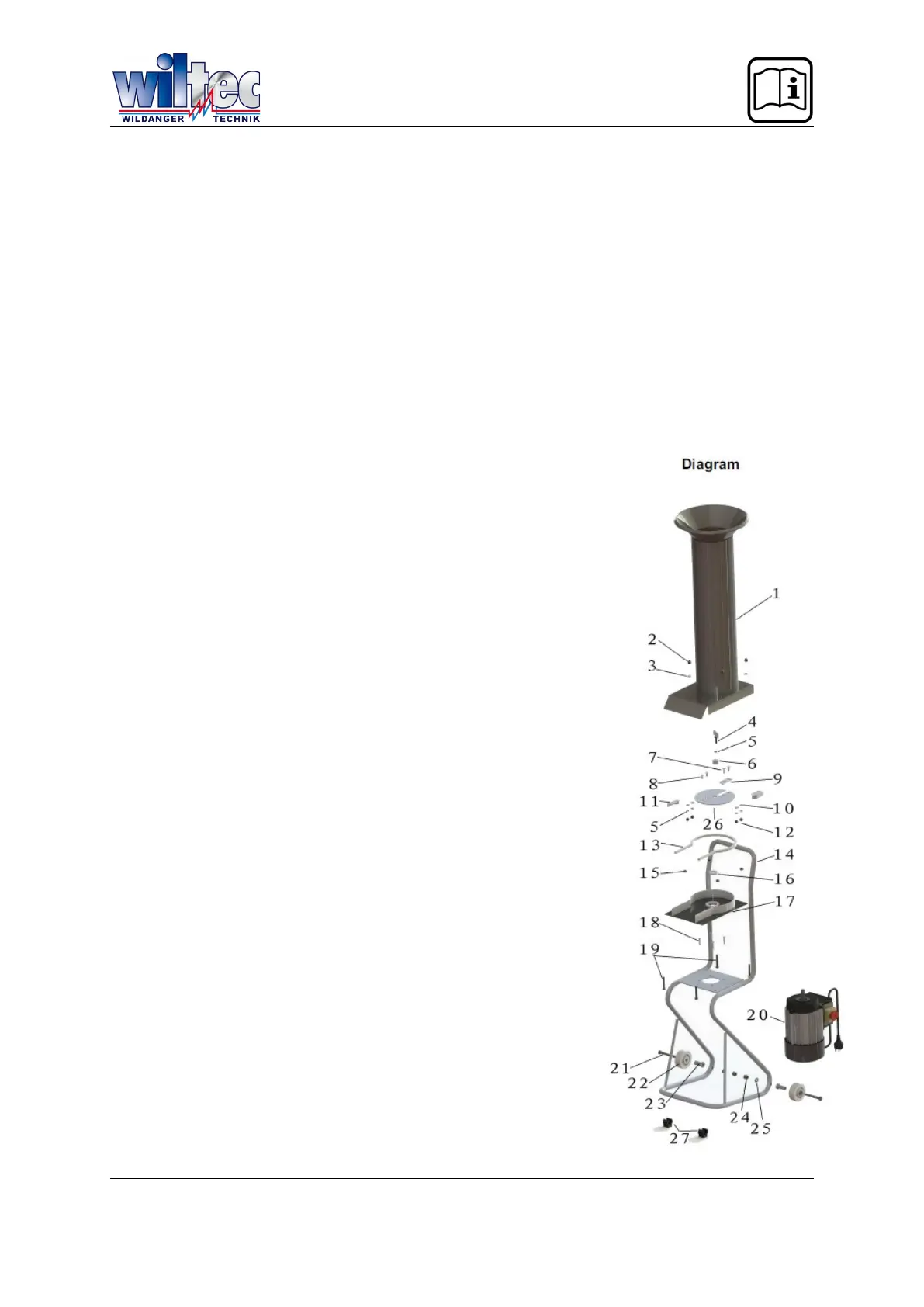

Part List

1. Hopper

2. M8 Cap Nut

3. φ8 Flat Washer

4. Rorary Plate

5. φ8 Spring Washer

6. Blade bushing

7. Inside-hex Countersunk Head Screw M8×16

8. Inside-hex Countersunk Head Screw M8×20

9. Blade

10. φ8 Flat Washer Stainless Steel

11. Cover Plate

12. M8 Lock Nut

13. Seal

14. Frame Stand

15. M8 Regular Nut

16. Oil Seal

17. Bottom Plate

18. Crossing Countersunk Head Screw M6×20

19. Outside-hex Bolt M8×50

20. Motor

21. Outside-hex Blot M10×80

22. Wheel

23. Wheel Shaft

24. M10 Lock Nut

25. φ10 Flat Washer

26. Blade Plate

27. Foot Block

© by WilTec Wildanger Technik GmbH Seite 13

http://www.WilTec.de

http://www.aoyue.eu

http://www.teichtip.de

Loading...

Loading...