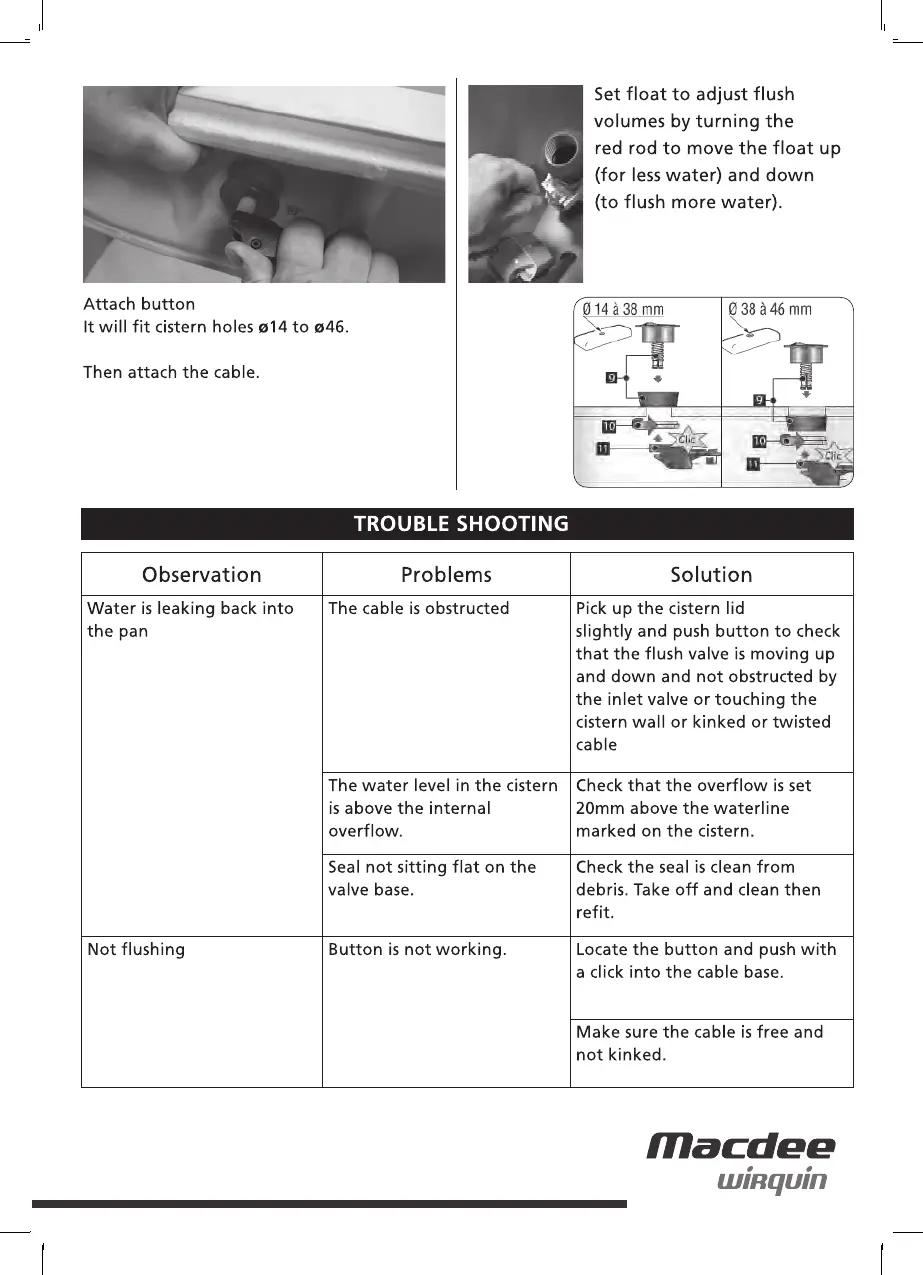

Observation Problems Solution

Water is leaking back into

the pan

The cable is obstructed Pick up the cistern lid

slightly and push button to check

that the flush valve is moving up

and down and not obstructed by

the inlet valve or touching the

cistern wall or kinked or twisted

cable

The water level in the cistern

is above the internal

overflow.

Check that the overflow is set

20mm above the waterline

marked on the cistern.

Seal not sitting flat on the

valve base.

Check the seal is clean from

debris. Take off and clean then

refit.

Not flushing Button is not working. Locate the button and push with

a click into the cable base.

Make sure the cable is free and

not kinked.

Important for new installations : before turning water on,

ensure that one cold water tap is open so that dirt and loose

particles in the pipe work are flushed through the tap (we

also recommend to flush through the water supply pipe to the

cistern before connection is made.

INLET VALVE

▼

Assembly instruction leaflet

• Jollyfill telescopic bottom entry inlet valve

SANITARY EQUIPMENT SPECIALIST

- Fit the filling valve. Ensure that the valve does not obstruct the

flush mechanism. Do not overtighten the back nut.

2

If pressure < 1 bar (15 p.s.i) :

cut here (gravity pressure/ header tank)

A : PRE-INSTALLATION

B : INSTALLATION

Turn off water supply to cistern and remove cistern

lid.

Flush the cistern and remove any loose dirt from

inside the tank.

Disconnect and remove the existing inlet valve.

Insert correct filter restrictor into threaded tail.

1

2

3

1

- Fit the filling valve. Ensure that the valve does not obstruct the

flush mechanism. Do not overtighten the back nut.

2

If pressure < 1 bar (15 p.s.i) :

cut here (gravity pressure/ header tank)

Fit the filling valve. Ensure that the valve does not obstruct

the flush mechanism. Do not overtighten the back nut

.

2

3

Connect water supply.

4

JOLLYFILL TELESCOPIC

BOTTOM ENTRY INLET VALVE

!

Turn on water supply. Allow the cistern to fill,

5

Adjust the water level,

A

Waterline

Internal overflow

2 cm

25 mm minimum

from internal overflow to

critical level (CL)

min 0 to

max

150mm

If the water level is not correct, turn off water supply.

Adjust the water level by : Turning slowly right or left to open.

Pulling up the body of the telescopic part, (see pic B).

Turning slowly right or left to lock. Turn on water supply.

B

B

A

Waterline

Internal overflow

2 cm

25 mm minimum

from internal overflow to

critical level (CL)

NOT OKOK

A

min 0 to

max

150mm

on inlet valve.

C

You can precisely adjust the float basin

with the red rod. Unclip the red rod

Adjust the float basin Clip the red rod.

C

Waterline

Internal overflow

2 cm

25 mm minimum

from internal overflow to

critical level (CL)

NOT OKOK

A

min 0 to

max

150mm

on inlet valve.

TROUBLE SHOOTING MAINTENANCE

FOR JOLLYFILL SIDE AND BOTTOM ENTRY VALVES

!

Turn off water supply before any maintenance is carried out.

A

B

2

2

Remove and wash

the diaphragm

and reassemble in

reverse order.

3

Remove and wash

the filter restrictor

and reassemble in

reverse order.

3

If pressure < 1 bar (15 p.s.i.) :

cut here (gravity pressure / header tank)

Adjustment rod

Float

Float basin

Threaded tail

Rubber washer

Back nut

Filter restrictor

!

NOT OKOK

Loading...

Loading...