16 Operation

MAN0943 (11/1/2013)

Figure 2. Tractor Front Weight

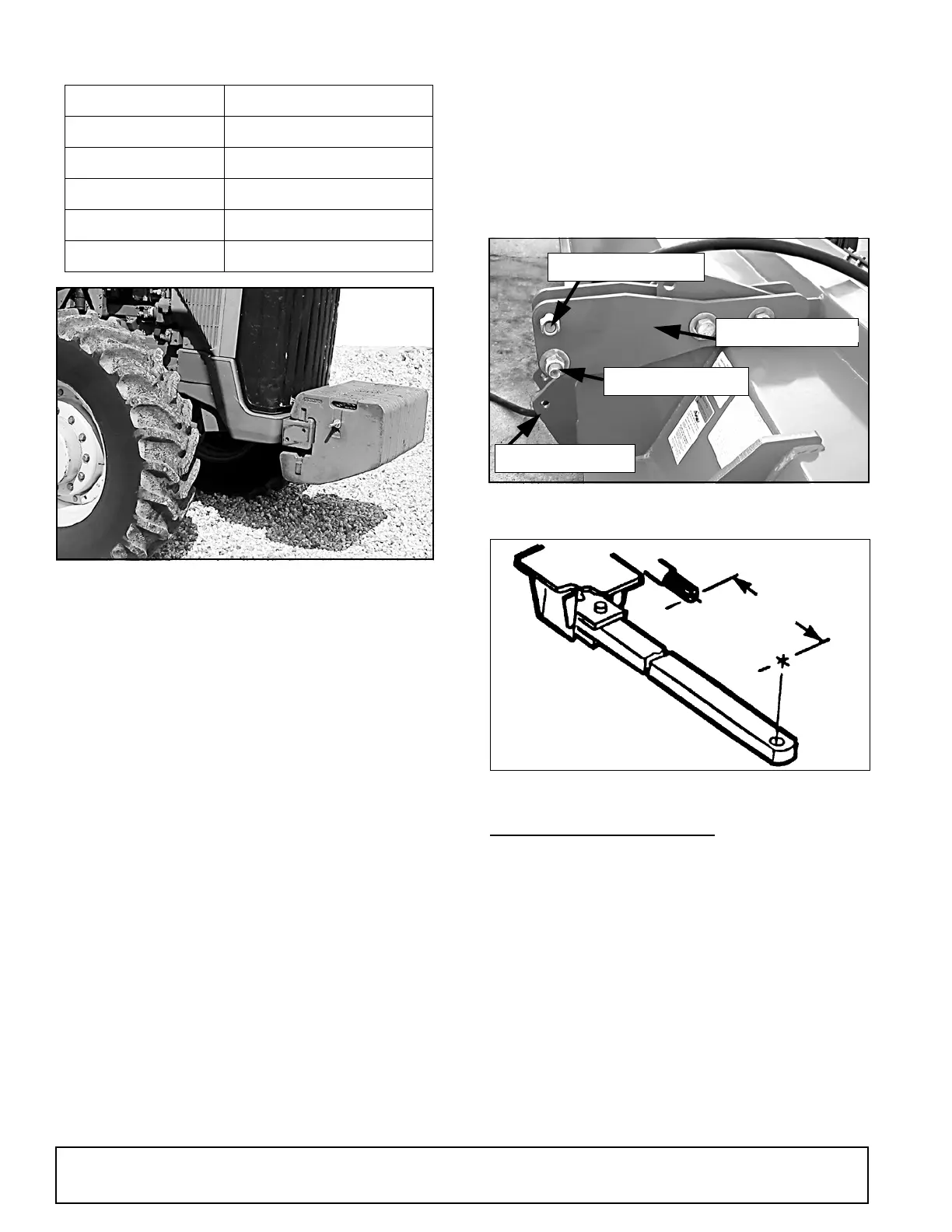

3. 3-Point Hitch

The 3-point hitch models require that the tractor be

equipped with a Category II or Category III 3-point

hitch. If the hitch can be converted from one to the

other, use a Category III to provide a wider stance and

more stability.

Use the upper top link hole for Category III and the

lower hole for Category II as shown in Figure 3.

For easier attachment, use a quick hitch. If not using a

quick hitch, use optional hitch extension.

4. Hydraulic Requirements when Using Center

Cutter Options

The tractor hydraulic system must be capable of 8 gpm

(30 lpm) at 1500 psi (10,335 kPa). The system cannot

exceed 28 gpm or 3000 psi. Either closed-centered or

open-centered systems can be used.

5. Load Sensing Hydraulics (3-Point Models Only)

Many newer tractors are equipped with “load sensing”

hydraulics. The operator is responsible for setting the

tractor hydraulic system to provide “float” on the 3-point

hitch. Refer to the tractor manual for specific instruc-

tions.

The “float” feature will allow the unit to follow the

ground contours during operation. This applies to 3-

point mounted machines only.

6. Drawbar (Pull-Type Models Only)

The tractor drawbar must be set to provide 20” (508

mm), between the end of the PTO shaft and the center

of the drawbar pin for 1-3/4 - 20, 1000 RPM drives. See

Figure 4. This dimension will provide the required

clearance for the CV (Constant Velocity) joint on the

front of the driveline.

NOTE: On Pull-Type models, do not cut driveline.

Figure 3. 3-Point Hitch Attachment

Figure 4. Drawbar Dimension

PTO DRIVELINE LENGTH

(3-Point & 2-point Models Only)

■

The unit is equipped with a PTO driveline long

enough to fit any tractor and 3-point linkage sys-

tem.

■

The operator is responsible for measuring the

dimensions of the driveline through its working

range. These dimensions will indicate if the drive-

line requires shorting to operate on the particular

tractor/unit attachment system. The operator must

check dimensions before using the unit for the first

time and each time a different tractor is used with

the unit.

■

Use the following procedure when determin-

ing driveline dimension:

Table 1: Tractor Horsepower (6-8) vs. Unit Width

Width Minimum Horsepower

20′ 120

22′ 132

25′ 150

27′ 162

30′ 180

Top Link Assembly

Upper Top Link Hole

Lower Top Link Pin

Lower 3-Point Pin

DP11

Loading...

Loading...