20 Operation

MAN0943 (11/1/2013)

NOTE: To avoid unnecessary wear on knives and

related parts, never set the unit lower than the recom-

mended setting. (See Balance Statement, page 5.)

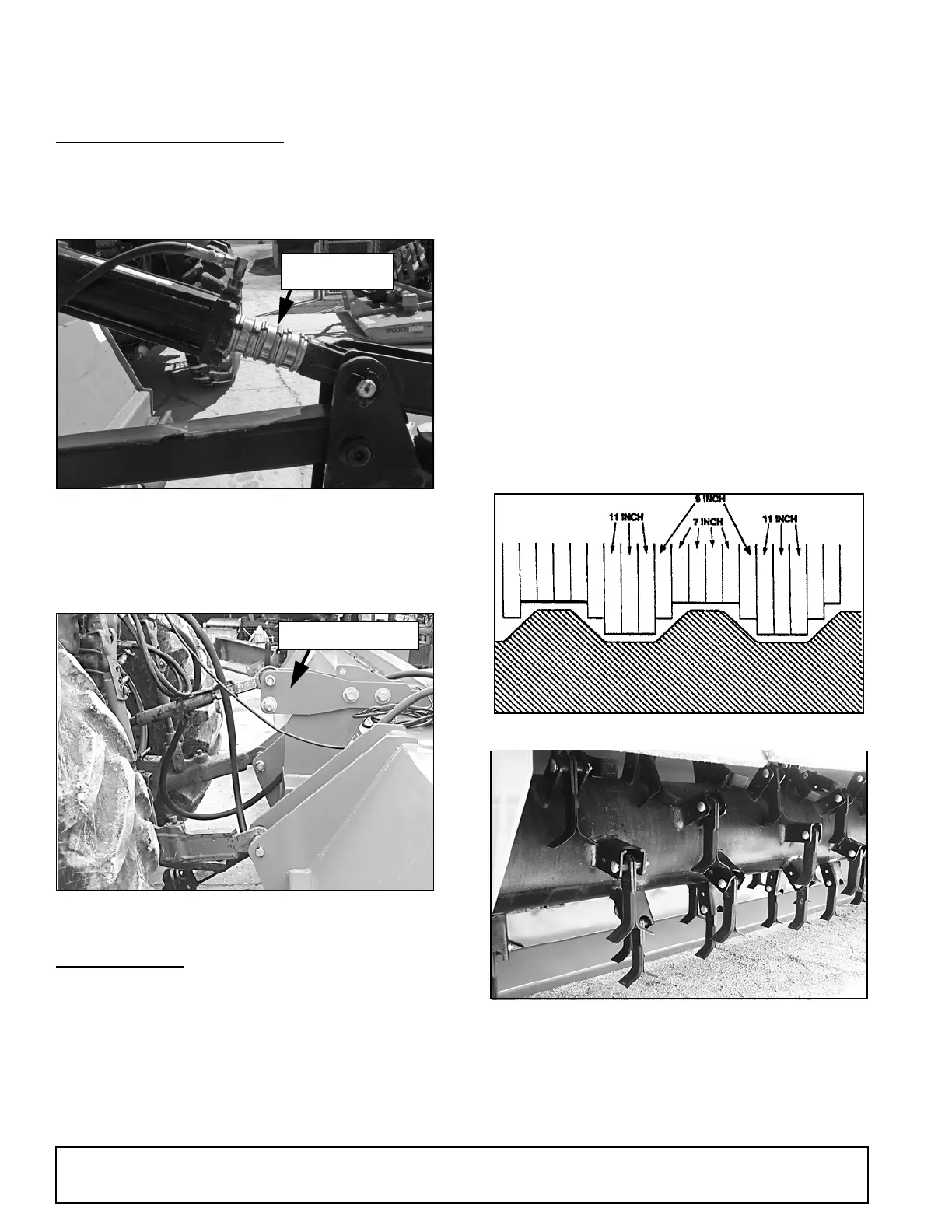

SET OPERATING HEIGHT

Use stroke control spacers. The number and thickness

should be equal on each cylinder to keep shredder

level.

Figure 10. Setting Operating Height

On 3-Point models, be sure the floating mast is free to

slide in its mounting frame to allow the machine to fol-

low ground contours. Refer to Figure 11.

Figure 11. Free-Float Position

FLAIL KNIVES

The shredder is factory equipped with “L” or cup type

flails. The two types are interchangeable.

“L” Flails

“L” flails (Figure 13) work best when trash or crop resi-

due is standing.

Cup Flails

Cup flails (Figure 14) can pick up material from the

ground and work best in matted trash conditions.

The standard cup flail is 8-1/2 inches (216 mm) long

and is used for most applications. Optional 6-3/16 inch

and 7-1/2 inch (157 mm and 191 mm) flails are avail-

able to match the tip position to ground contour.

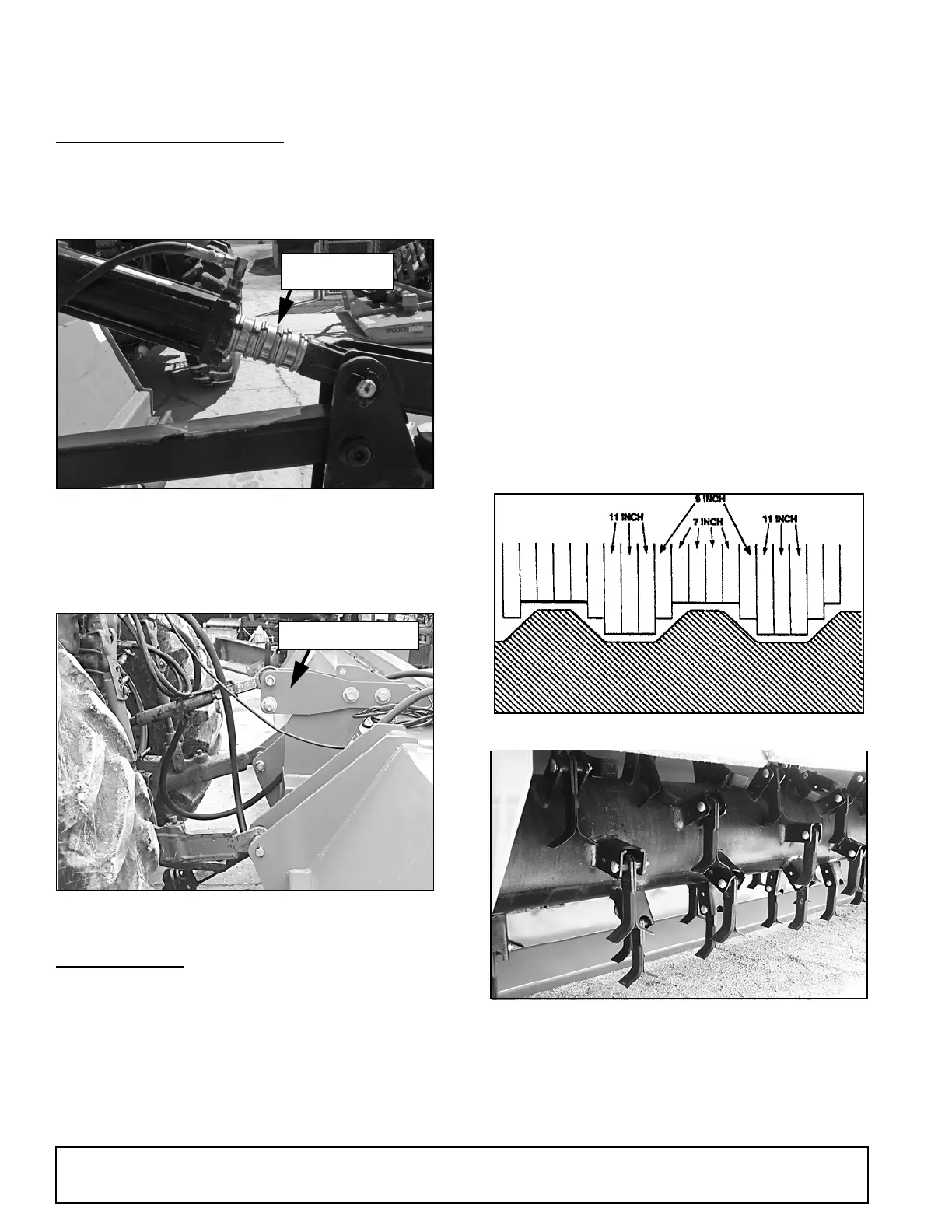

Attach optional cup flails as follows, making sure that

knives at 180° match (see Figure 12) (see Balance

Statement, page 5):

1. Leave standard flails located between the rows.

2. Remove others and install shorter flails to follow

ground contour. Be sure to mount the same size

flails on opposite sides of the tube. Measure the

row spacing and flail position carefully to minimize

ground contact. See page 38 and page 39.

.

Figure 12. Optional Flail Contour

Figure 13. “L” Flails

Stroke Control

Spacers

DP124

Loading...

Loading...