11

EN

5.MAINTENANCE

Remove the battery before carrying out any adjustment, servicing or

maintenance.

There are no user serviceable parts in your power tool. Never use water or

chemical cleaners to clean your power tool. Wipe clean with a dry cloth.

Always store your power tool in a dry place. Keep the motor ventilation slots

clean. Keep all working controls free of dust. Occasionally you may see sparks

through the ventilation slots. This is normal and will not damage your power

tool.Store the accessories in a dry place.

Warning: Do not use inflammable solvents for cleaning the surfaces to be

glued. For excess hardened glue, it can be removed with a blunt object. Do

not use solvent for cleaning.

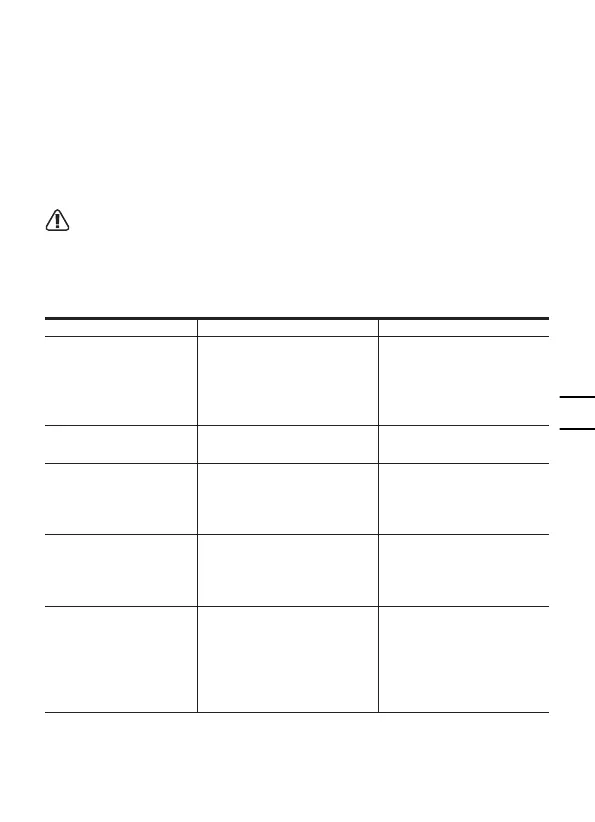

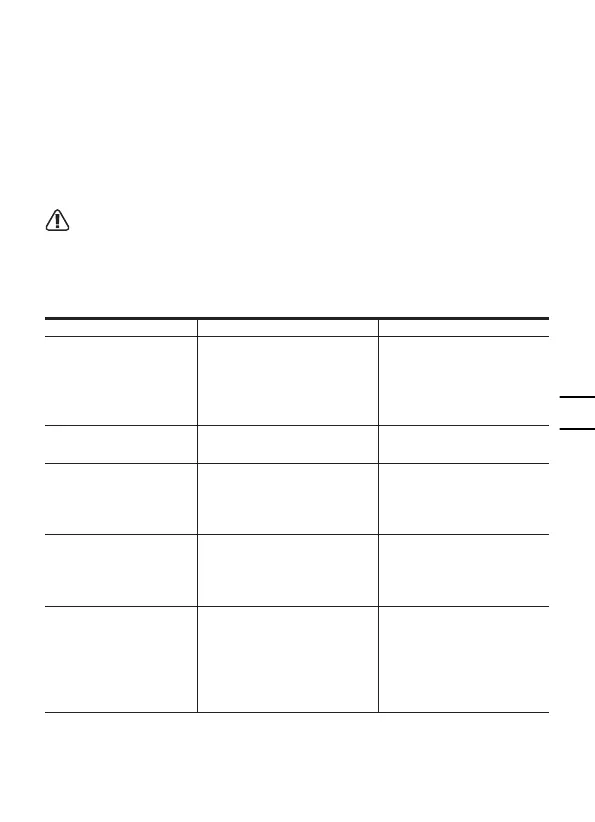

6.TROUBLESHOOTING

Problems Possible Causes Possible Solution

No glue comes out Glue stick is used up.

Glue stick diameter is too

large or small.

Glue stick is not pushed

to the end.

Insert a new glue stick.

Use recommended glue

sticks.

Push the glue stick to

the end when loading.

Glue stick falls out

from the tool.

Glue stick diameter is too

small.

Use recommended glue

sticks.

There is glue leaking

out without trigger

pressed after use.

The temperature is still

high in short time after

use and will cause glue to

melt.

It is normal and will stop

leaking out when the

glue gun cools down.

Trigger is blocked for

glue escaping toward

the rear.

Glue stick diameter too

small.

Glue stick’s melting

temperature is too low.

Use recommended glue

sticks.

Glue does not flow

evenly.

Glue stick’s melting

temperature is too low.

Glue is not heated long

enough.

Trigger is not pressed

uniformly.

Wait for heating.

Allow the glue gun time

to heat up.

Press trigger slowly and

uniformly.

Loading...

Loading...