Random orbital sander WX652 WX652.1

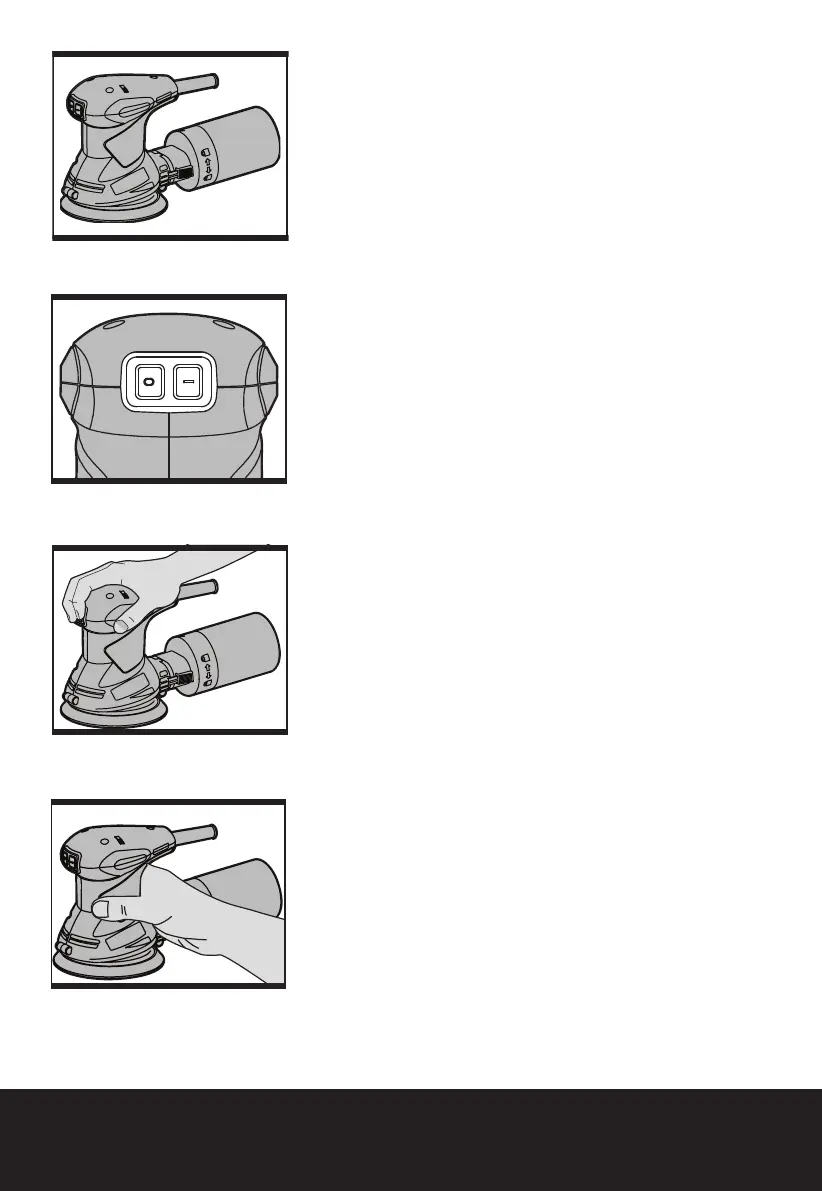

Your sander is designed to be held either around the

main housings, or by the top of the main housing.

When sanding for long periods at a time, it is

recommended you periodically alternate between the

two holding positions.

5. SANDING SURFACES

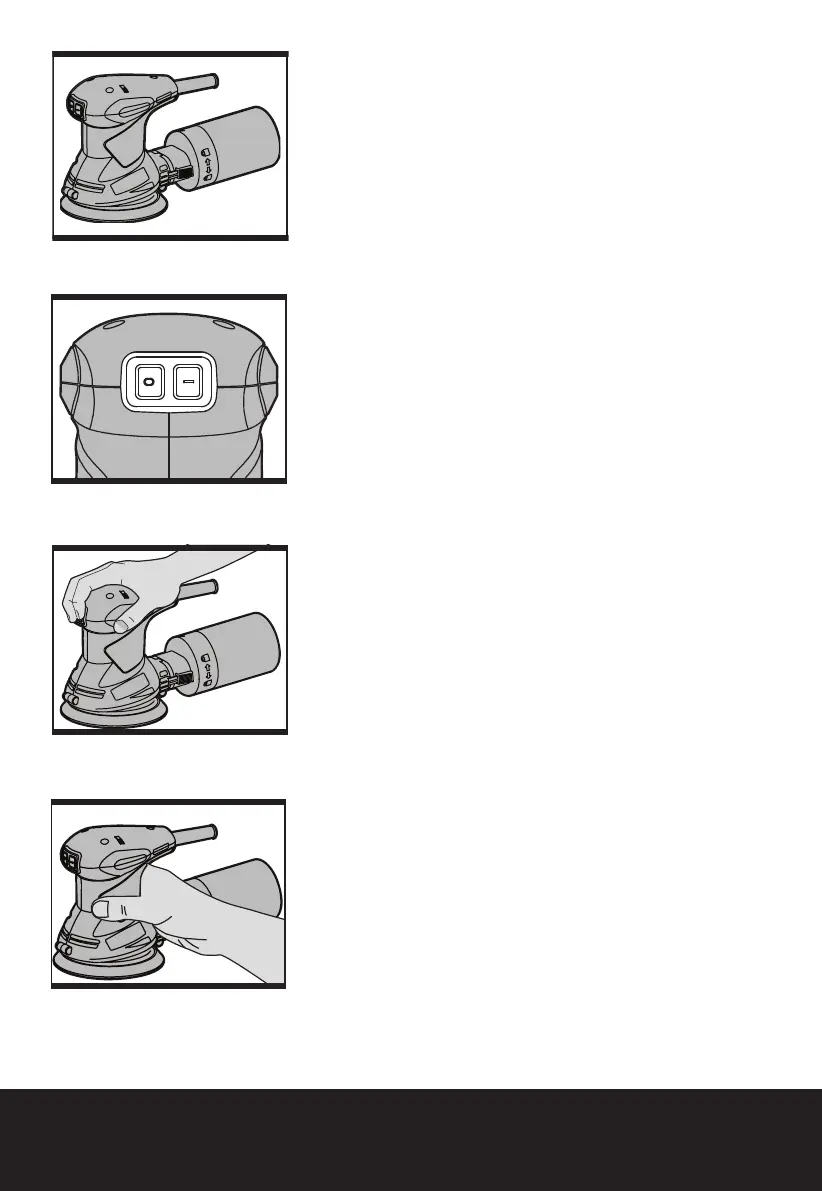

Place the machine with the complete Sand paper on

the surface to be worked. Ensure uniform sanding

pressure. Less sanding pressure increases the sanding

capacity and protects the machine and the sanding

tool. The removal capacity and the sanding pattern are

determined mainly by the selection of the Sand paper

(grain size), the speed of the sanding plate and the

application pressure.

ROUGH SANDING

Attach a Sand paper with coarse grain. Apply only

light sanding pressure to achieve increased material

removal.

FINE SANDING

Attach a Sand paper with fine grain. With moderate

pressure, move the machine in a circular pattern or

alternately in lengthwise and crosswise directions over

the workpiece. Do not tilt the machine to avoid sanding

through the work piece (e.g. when sanding veneer).

After finishing the work, switch off the machine and lift

it from the workpiece.

6. ORBITAL SANDING

Guide your sander parallel to the working surface and

move it in circles or in a cross pattern. Do not tilt the

tool in order to avoid deep unwanted sanding marks.

The amount of material removed is determined by the

speed of the sanding disc and the grit size used. The

speed of the sanding disc diminishes relative to the

pressure applied to the tool. For faster removal, do not

increase pressure on the tool, but use a coarser grit

size.

7. SELECTING THE RIGHT GRADE OF

SANDPAPER

— Different grades of sanding paper can be purchased

from good DIY shops. Available grades are Coarse,

Medium and Fine.

— Use coarse grits to sand down rough finishes,

medium grit to smooth the work and fine grit to

finish off.

— The higher the grade number, the finer the grit. For

rough work start with a low grade of grit. (e.g. 60

grit) and change to a higher, finer grade (e.g. 120

D

E

F

G

Loading...

Loading...