en - Original instructions

34

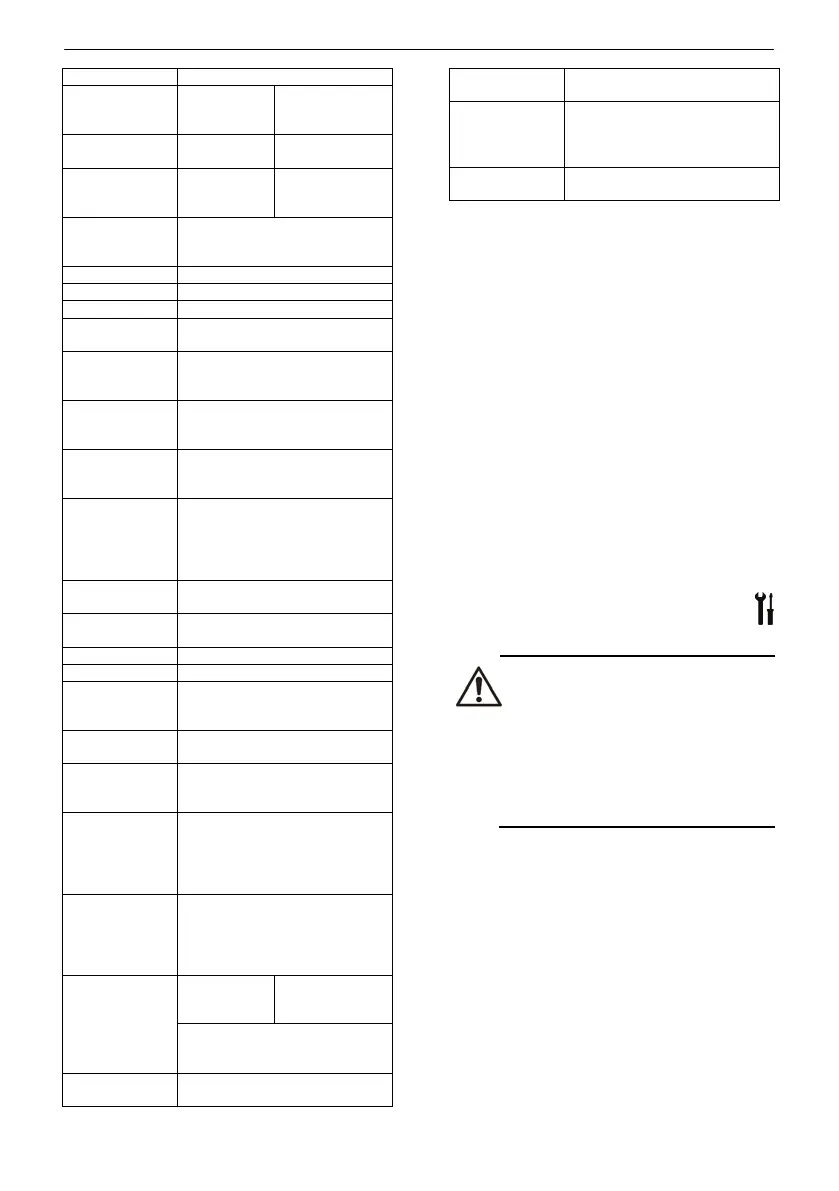

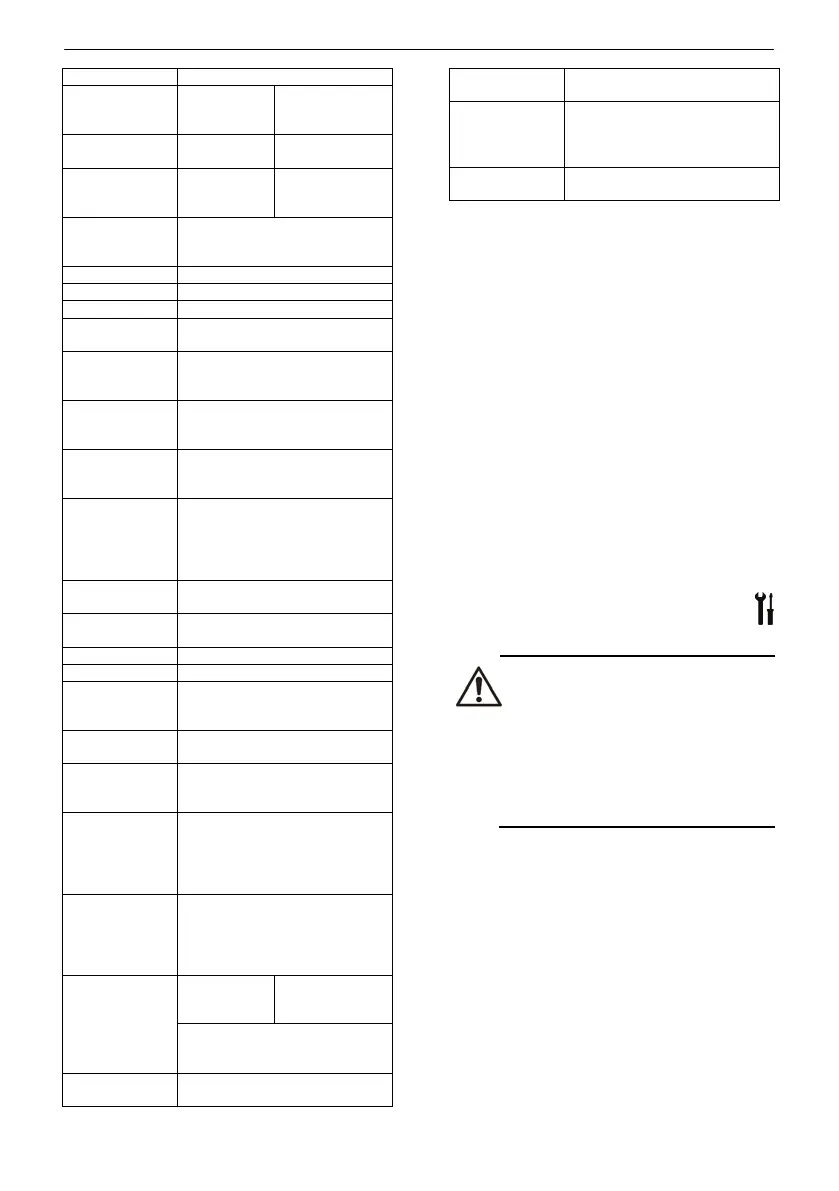

rent

1

12A 24A

Recommended

line protection

2

20A 40A

current

12 A 2 x 12 A

standby

(standby power may vary according

to the type of sensor connected)

Self-extinguishing - grey

55

Connections

(use copper

conductor only)

Screw terminal blocks

(power supply, input and output)

Maximum input

power cable

section

4 mm

2

Maximum motor

power cable

section

4 mm

2

Set point

3

Pressure: 0 to 60 bar (0 to 6

MegaPa)

Level: 0 to 50 m (0 to 164 feet)

Temperature: -20 to 100°C (32

0 to 40°C (32 to 122°F)

10 to 90% non-condensing

fuse F1, F2

CH10

Auxiliary protec-

tion fuse F3

1A Time-Lag 5 x20 mm

(T1L 250V IEC60127-2/3)

Digital inputs

5 multifunctional inputs for

NO/NC contact (voltage-free,

inputs

4 level electrode sensors,

1 reference electrode

Sensitivity: 5 to 100kOhm,

Line capacity: 10nF max,

Electrode voltage: 6.5V - 20Hz

Analogue input

(Sensor active value input)

Current input 0-22 mA, accuracy

0.3%,

Sensor power supply +12 Vdc

Digital outputs

1 Load relay 2 Load relays

Maximum current allowed for

the electric motor is 12A

TTL Serial port

Port for communication with the

supervision system via TTL with

ModBus communication protocol

Signals: +5V, RX, TX, RTS, 0V

RJ45 connector

Port RJ45 for communication with

the card with voltage-free relays

Signals: +12V - 120mA , 0V,

See Figure 3

1. The current supplied by the control panel shall

not be lower than the current absorbed by the

electric pumps, and depends also on the volt-

age drop due to the length of the cable.

2. Choose the current of the line protection de-

vice in relation to the maximum current ab-

sorbed by the motors.

3. Only if the electronic sensor is used.

4. For higher altitudes or other environmental

conditions not covered in this manual, please

contact your local After Sales / Service repre-

sentative.

3.4

Pump specifications

Refer to the user and maintenance manual of the

electric pump. It is essential to consider the limita-

tions of use of the control panel together with

those of the electric pump. See the

Technical data in

Tab 1. The customer is respon-

sible for checking the limitations of the electric

pump if they are not specified in this manual.

4 Installation

Precaution

• Observe the accident prevention

regulations in force.

• Use suitable equipment and protec-

tive devices.

• Always refer to the local regula-

tions, legislation and codes in force

regarding the selection of the instal-

lation site, plumbing and power

4.1

Electrical requirements

The local regulations in force overrule the specific

requirements given below.

Electrical connection checklist

Check that the following requirements are met:

• The electrical leads are protected against high

temperature, vibrations and collisions.

• The current type and voltage of the mains

connection must correspond to the specifica-

tions on the data plate on the pump.

• It is recommended to provide electrical power

to the control panel with a dedicated power

line equipped with:

Loading...

Loading...