27

©

2019 Columbus McKinnon Industrial Products GmbH

Do not use the chain end stop as an operational limit device.

The load must not be moved into areas which are not visible to the operator. If necessary, he must seek help.

The following are applicable to devices in a trolley:

The longitudinal downward slope of the carriageway must not exceed 0,3 %.

The adjustment of the trolley width must not be extended in order to e. g. obtain a smaller radius curvature.

Any modification of the lifting device is prohibited. A unit modified without consulting the manufacturer must not be used.

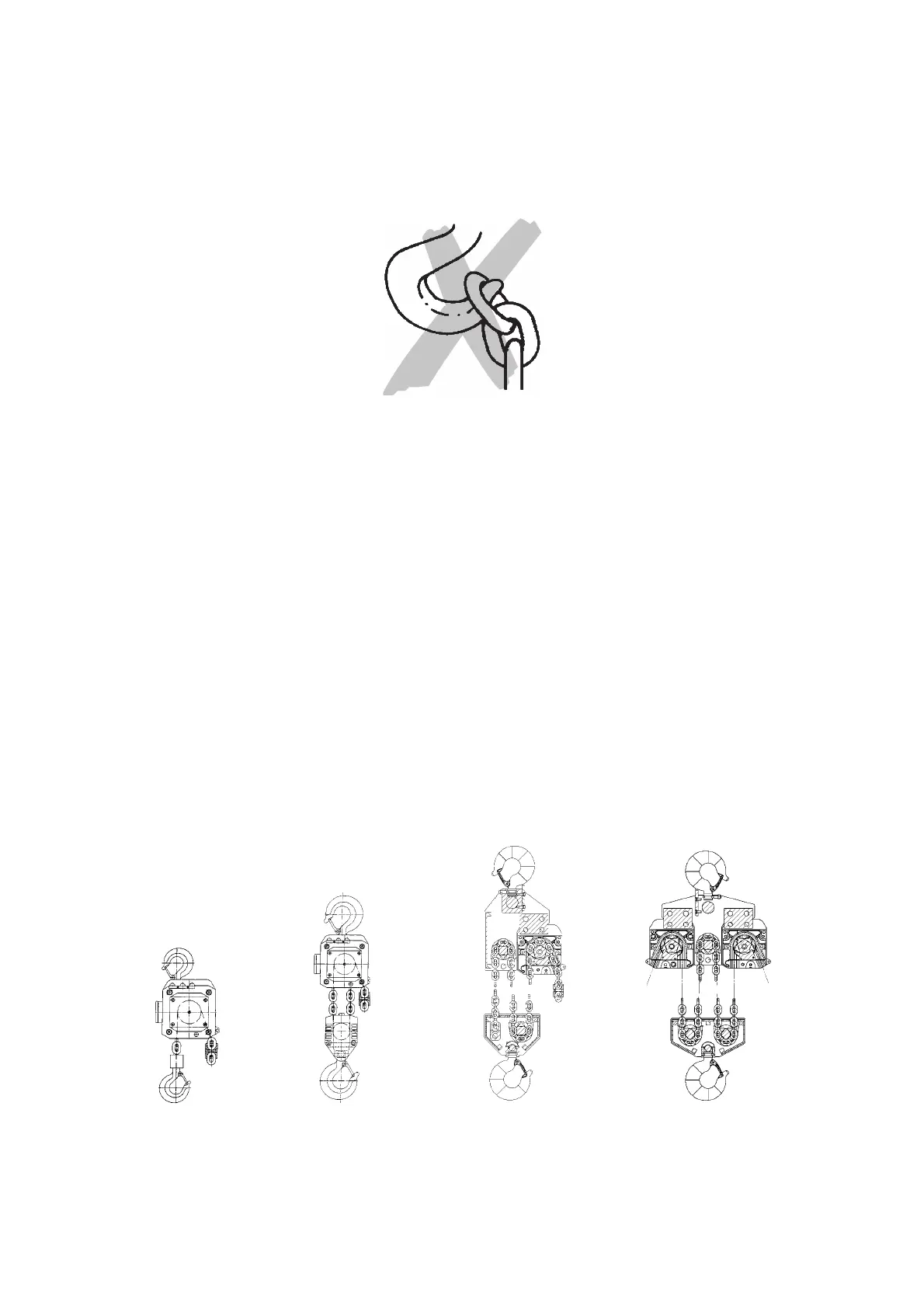

Never attach the load to the tip of the hook. The load must always be seated in the saddle of the hook. This also applies to the

suspension hook.

Turning of loads under normal operating conditions is not allowed, as the bottom blocks of the hoists are not designed for this purpose.

If turning of loads is required as standard, the bottom blocks have to be provided with swivel hooks supported by axial bearings. In case

of queries consult the manufacturer.

Do not throw the hoist or trolley down. Always place it properly on the ground.

Never reach into moving parts.

Only one load lifting attachment may be suspended in the load hook of the hoist.

The unit must not be operated in potentially explosive atmospheres.

A

SSEMBLY

Assembly and maintenance of the device is to be entrusted only to persons who are trained in the field in question and have been

commissioned by the owner to assemble and service the device.

These persons must know the common accident prevention rules, e.g. "Winches, lifting and hoisting devices (DGUV Vorschrift 54)",

"Cranes – power driven winches (EN14492-1)" etc., and must be appropriately trained. They should also be familiar with the operating

and installation instructions drafted by the manufacturer.

NOTE: If the unit is operated in the open, it must be appropriately protected against adverse weather conditions (e.g. by roofing).

Inspection Before Assembly

Check for transport damage

Check for completeness

Check that the capacity indication on hoist and bottom block match.

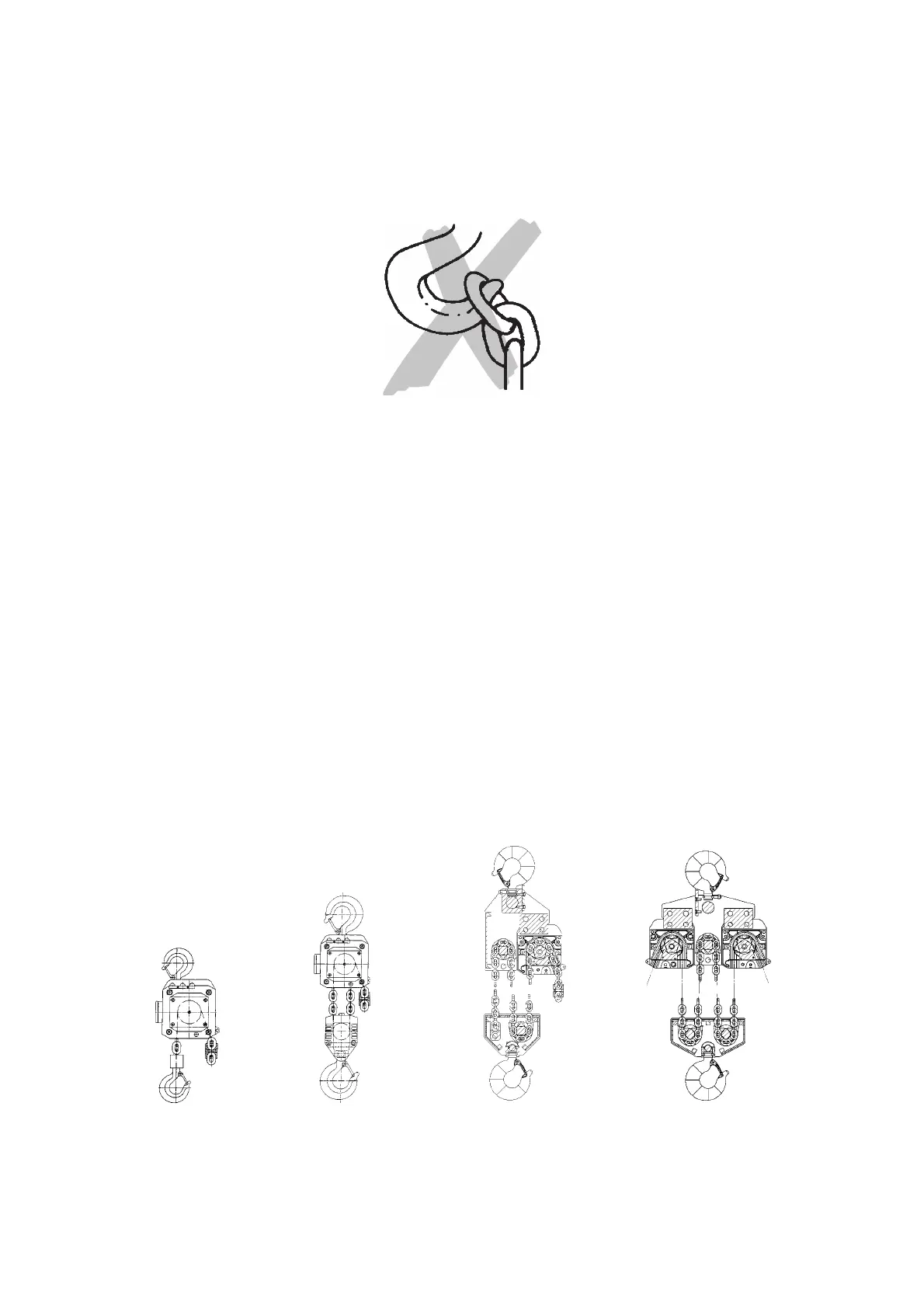

Electric Chain Hoist With Suspension Bracket (Standard version)

The standard version of the Yale electric chain hoist is provided with a suspension bracket. The bracket is connected with the housing of

the chain hoist by means of two bolts. Make sure that the load hook – irrespective of the reeving – is always positioned vertically under

the suspension bracket.

In 1-strand configuration the suspension hook is to be installed centred on the marking "1/1" on the main frame assy. , in 2-strand

configuration centred on the marking "2/1", In 3- and 4-strand configuration the suspension hook is to be installed centred on the

marking "1/1" on the main frame assy.

Attention: Secure the two suspension pins with locking plate after assembly.

Selection and calculation of the suitable suspension point and beam construction are the responsibility of the user.

Loading...

Loading...