Non-Sound Decoder MX600 - MX638 and Sound Decoder MX640 - MX659 Page 19

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

250

0 20 40 60 80 100 1 50 2 00 252

D

e

f

a

u

l

t

c

o

m

p

e

n

s

a

t

i

o

n

c

u

r

v

e

C

V

#

5

8

=

2

5

5

,

C

V

#

1

0

u

n

d

#

1

1

3

=

0

F

u

l

l

c

o

m

p

e

n

s

a

t

i

o

n

a

t

l

o

w

s

p

e

e

d

,

d

r

o

p

p

i

n

g

o

f

f

t

o

0

a

t

f

u

l

l

s

p

e

e

d

.

Comp. influence

Int. speed step

A

l

t

e

r

e

d

c

o

m

p

e

n

s

a

t

i

o

n

c

u

r

v

e

C

V

#

5

8

=

1

8

0

,

C

V

#

1

0

u

n

d

#

1

1

3

=

0

R

e

d

u

c

e

d

c

o

m

p

e

n

s

a

t

i

o

n

o

v

e

r

t

h

e

w

h

o

l

e

s

p

e

e

d

r

a

n

g

e

.

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

250

0 20 40 60 80 100 150 200 252

D

e

f

a

u

l

t

c

o

m

p

e

n

s

a

t

i

o

n

c

u

r

v

e

A

l

t

e

r

e

d

c

o

m

p

e

n

s

a

t

i

o

n

c

u

r

v

e

C

V

#

1

0

=

1

2

6

,

C

V

#

1

1

3

=

2

0

0

,

I

n

c

r

e

a

s

e

d

c

o

m

p

e

n

s

a

t

i

o

n

i

n

t

h

e

m

e

d

i

u

m

s

p

e

e

d

r

a

n

g

e

.

rate

.

01 - 99

High

frequency

with

modified

sampling

rate.

255-176

Low

frequency

tens digit for sampling rate and

ones digit for sampling time.

Tens digit 1 - 4: Lower sampling rate than default

(less noise!)

Tens digit 6 - 9: Higher sampling rate than default

(to combat juddering!)

Ones digit 1 – 4: Shorter EMF sampling time

(good for coreless motors, less noise, more power)

Ones digit 6 - 9: Longer EMF sampling time

(may be needed for round motors or similar).

Typical test values against jerky driving:

CV #9 = 55 (default) 83, 85, 87, ...

CV #9 = 55 (default) 44, 33, 22, …

= 255 - 176: Low frequency (for old motors only!) –

PWM according to formula (131+ mantissa*4) *2exp. Bit 0-4 is

“mantissa”; Bit 5-7 is “exp”. Motor frequency is the reciprocal of

the PWM.

Examples:

#9 = 255: frequency at 30 Hz,

#9 = 208: frequency at 80 Hz,

#9 = 192: frequency at 120 Hz.

Special ZIMO

configuration bits

Bit 1 = 0: Normal acknowledgement.

= 1: High frequency acknowledgement

Bit 2 = 0: Loco number recognition OFF

= 1: ZIMO loco number recognition ON

Bit 3 = 0: 12-Function Mode

= 1: 8-Function Mode

Bit 4 = 0: Pulse chain recognition OFF

= 1: Pulse chain recognition (for old LGB)

Bit 5 = 0: 20 kHz motor control frequency

= 1: 40 kHz motor control frequency

Bit 6 = 0: normal (also see CV #29)

= 1: „Märklin brake mode

P and I value

For

BEMF motor regulation

55

medium

PID

setting

01 - 199

modified

settings

= 55: Default setting using medium PID parameters.

= 0 - 99: Modified settings for “normal” DC motors.

= 100 - 199: Modified settings for coreless motors

(Faulhaber, Maxxon etc.)

Tens digit 1 - 4: Lower proportional value than default

Tens digit 6 - 9: Higher proportional value than default

Ones digit 1 - 4: Lower integral than default

Ones digit 6 - 9: Higher integral than default

Typical test values against jerky driving:

CV #56 = 55 (default) 33, 77, 73, 71, ..

EMF – Extended

sampling time

Useful initial test value: 20.

For Fleischmann motors

Values too small cause engine to stutter, values too big

worsens the regulation at low speeds.

Fine-tuning suggestions (if default settings are not satisfactory):

“Normal” modern Roco engine

Means high sampling rate at low load; reduced rate at

higher load to prevent loss of power.

Fleischmann “round motor”

Also recommended: CV #2 = 12, CV #147 = 60

From SW version 31: CV #145 = 2

(Attention: often helpful – remove suppressor compo-

nents.

Small coreless (Faulhaber, Maxxon

or similar)

The stronger the motor, the weaker the regulation is

set to avoid overshoots, the integral component never-

theless provides for full load regulation.

Large coreless (O gauge or larger)

Tips on how to find the optimal CV #56 settings:

Start with an initial setting of CV #56 = 11; set the engine at low speed while holding it back with one

hand. The motor regulation should compensate for the higher load within half a second. If it takes

longer than that, increase the ones digit gradually: CV #56 = 12, 13, 14...

With the locomotive still running at a low speed, increase the tens digit in CV #56. For example: (if the

test above resulted in CV #56 = 13) start increasing the tens digit CV #56 = 23, 33 ,43…as soon as

juddering is detected, revert back to the previous digit this would be the final setting.

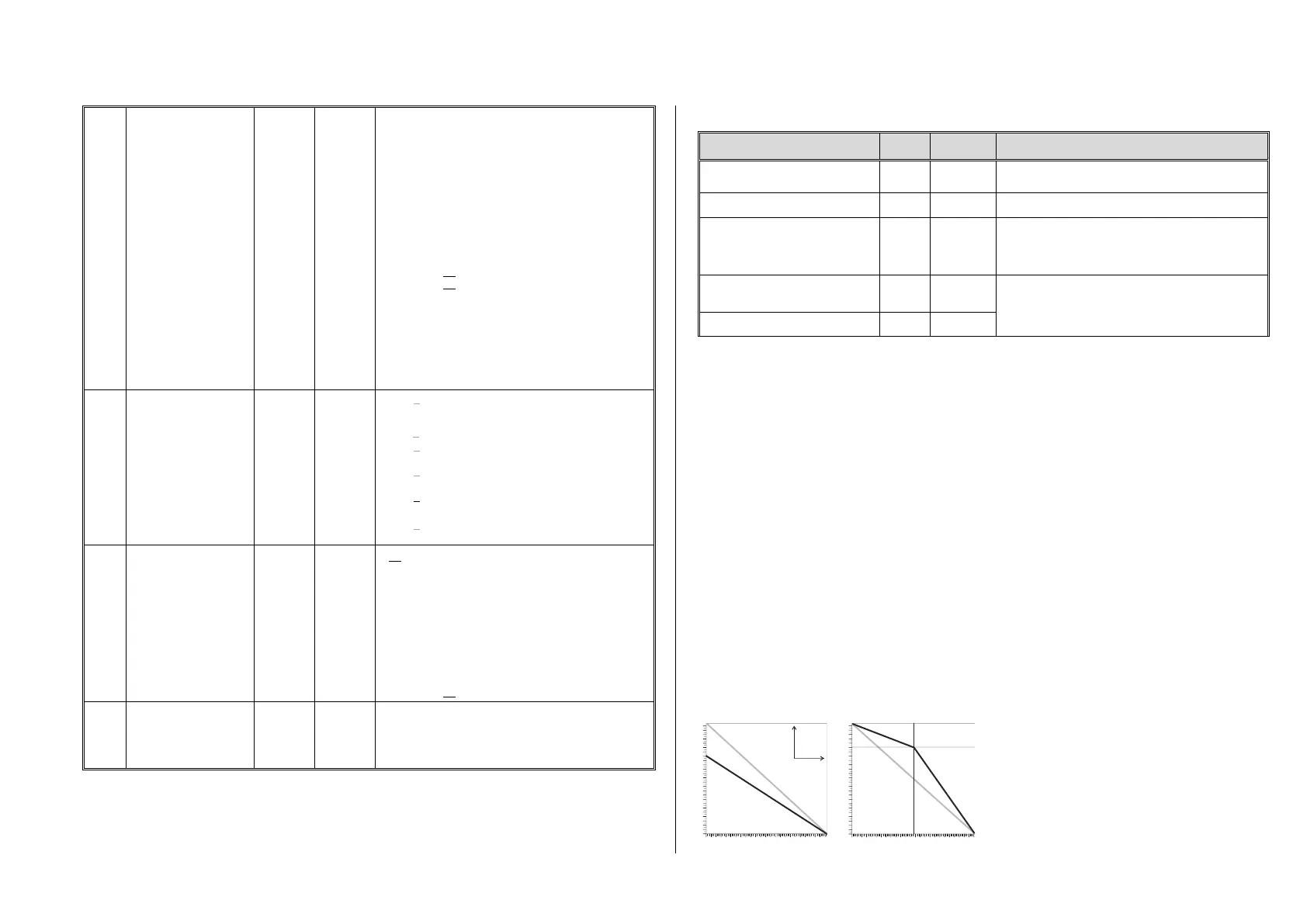

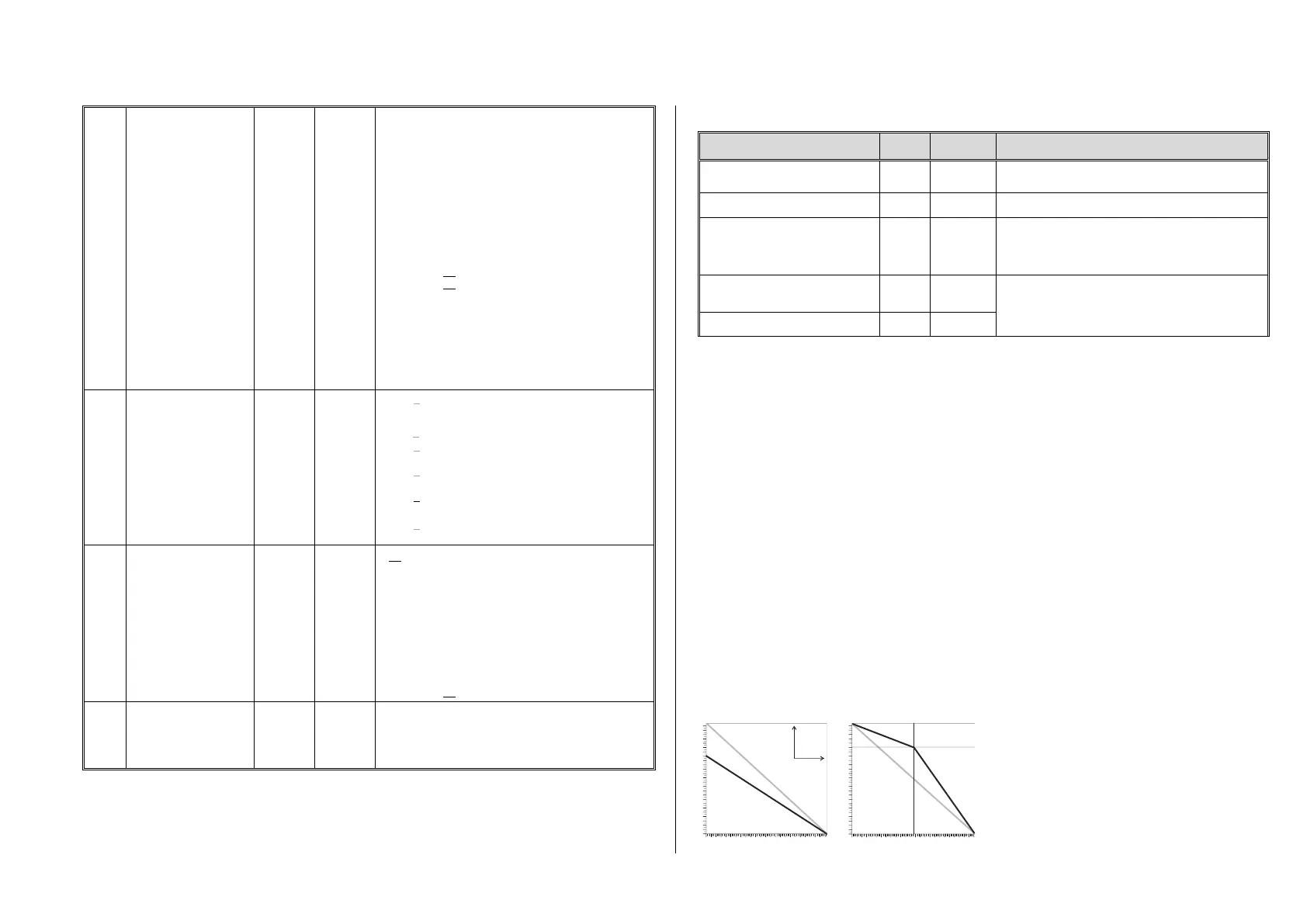

Load Compensation, Compensation Curve and Experimental CV’s

The goal of load compensation, at least in theory, is to keep the speed constant in all circumstances

(only limited by available power). In reality though, a certain reduction in compensation is quite often

preferred.

100% load compensation is useful within the low speed range to successfully prevent engine stalls or

run-away under light load. Load compensation should be reduced as speed increases, so that at full

speed the motor actually receives full power. Also, a slight grade-dependent speed change is often

considered more prototypical.

Locomotives operated in consists should never run at 100% load compensation, in any part of the

speed range, because it causes the locomotives to fight each other and could even lead to derail-

ments.

The overall intensity of load compensation can be

defined with CV # 58 from no compensation

(value 0) to full compensation (value 255). Useful

values range from 100 to 200.

For a more precise or more complete load com-

pensation over the full speed range use CV #10

and CV #113 together with CV #58 to define a 3-

point curve.

Loading...

Loading...