15

PROCEPTOR

OWNER'S MANUAL

Maintenance: Coalescer

Regularly monitor oil and sediment level in your Proceptor separator.

When the separator is pumped out, Zurn Green Turtle recommends cleaning the coalescer system at the same time. The

coalescer may become plugged up if the loading solids are too high in the influent wastewater. Although this will not aect

flow through the separator, it may reduce the oil removal eciency and expose the Owner/Operator to unnecessary liability.

To clean the coalescer system:

1 Visually inspect the unit from the accessway to make sure there is no obstruction on top of the coalescer, and the lifting

device is secured. There may be tabs bolted on the bae to hold the coalescer in place during the original shipment.

Swivel them out of the way if they are holding the coalescer down.

2 Pull the handle gently to lift and remove coalescer pack(s) one at a time.

3 Use caution when handling the coalescer packs to avoid damage.

4 Inspect for damage. Ensure frames are intact.

5 Rinse each coalescer pack with low-pressure clean water. Note: Do not use soap in the cleaning process. Tip: Before the

separator is pumped out, suspend each pack over the tank accessway using a bar through the handle at floor level. The

rinse water will flow back into the tank and be pumped out by the waste maintenance company.

6 Look through the porous sides of the pack to ensure channels are clear. If low-pressure flow will not clear the channels

due to packed solids, a high-pressure wash may used. Use care not to damage the internal parts of the pack with a high-

pressure wash.

7 Ensure all oil, water and sediment is pumped out/removed from the oil separator until it is clean to the bottom.

8 Ensure the frames in the Proceptor bae inside the tank are free of debris, especially at the bottom where the coalescer

is installed.

9 Before refilling the separator with clean water, reinstall each pack by lowering carefully into the bae frame, making sure

pack(s) are seated and level with the top of the bae. When the coalescer packs are equipped with vertical guide bars (a

feature added in 2007), it prevents the packs from being reinstalled incorrectly. These bars protrude from the box frame.

Note: If the coalescer system does not have guide bars, ensure the pack(s) are installed with the open-celled sides facing the

inlet and outlet. The top and bottom of the packs also have open cells. If installed incorrectly, wastewater will flow over the

coalescer instead of flowing through it.

Refill the separator with clean cold water. Do not add soap

to the unit.

An alternative to pulling out coalescer packs is to pressure

wash them in place after the tank is pumped out during

scheduled maintenance. Please ensure the water used to clean

the coalescer system is also pumped out.

However, Zurn Green Turtle recommends removal of the

coalescer packs for optimal cleaning and inspection.

Repair

If a coalescer system appears damaged call your Zurn Green

Turtle representative for further information.

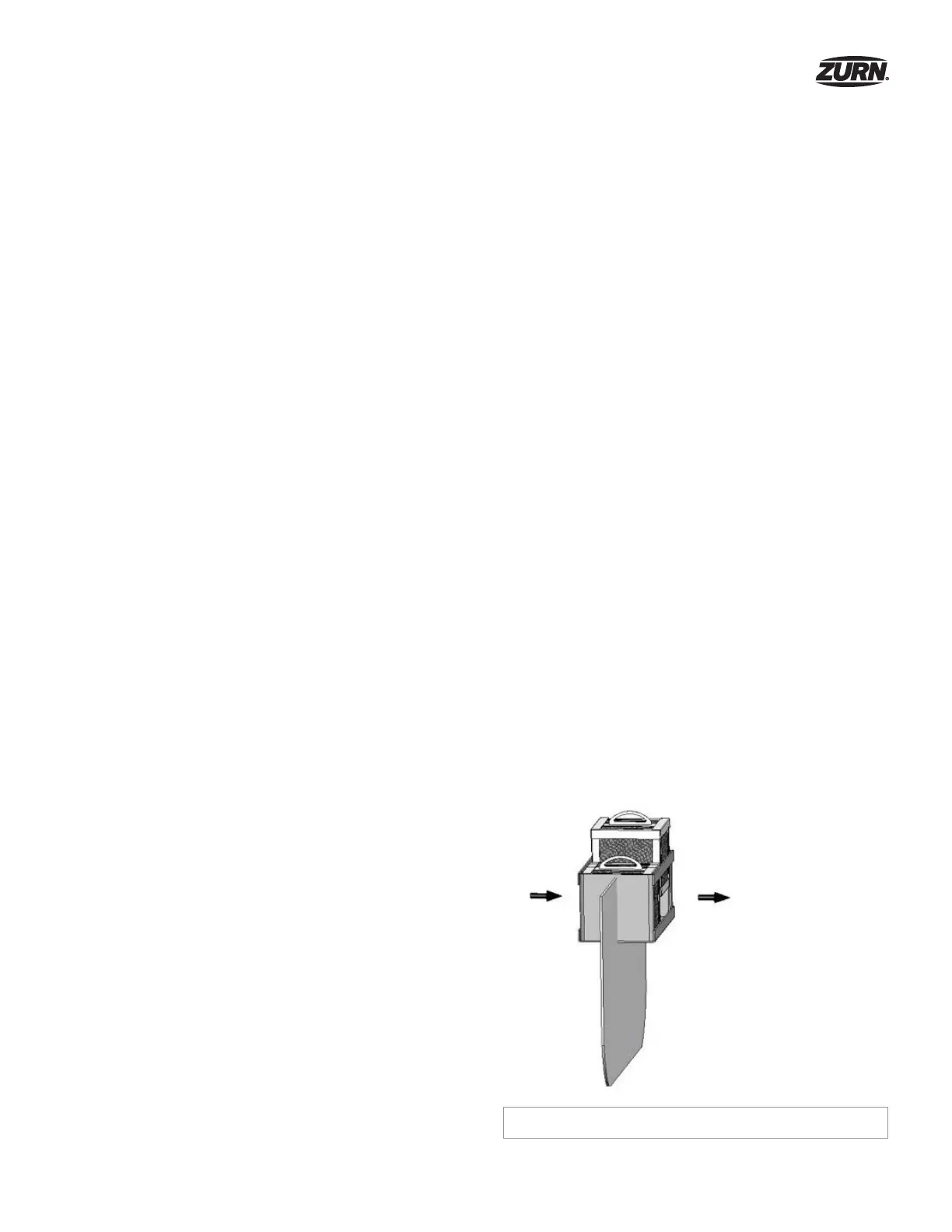

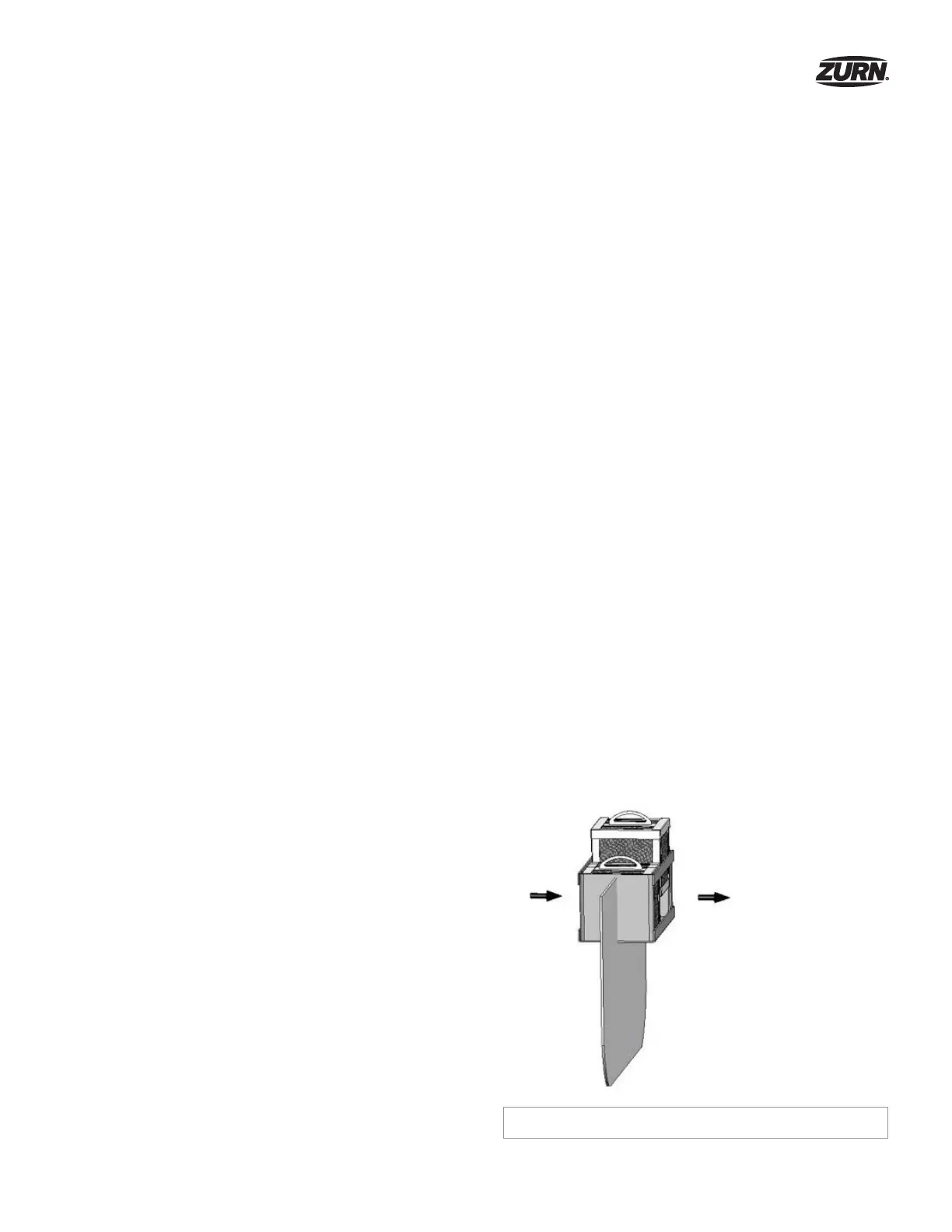

Figure 6: Typical coalescer construction

Illustrating one bae

pack partially lifted. Pack

configuration varies with

separator model.

Direction of

wastewater flow.

Loading...

Loading...