3M Two Hand 6 in. ROS 2 Revision 052209

To reduce the risk of all hazards associated with vibration:

• If any physical hand/wrist discomfort is experienced, work should be stopped promptly to seek medical attention. Hand, wrist and arm

injury may result from repetitive work, motion and overexposure to vibration.

To reduce the risks associated with loud noise:

• Always wear protection for eyes, ears, and respiratory protection while operating this product. Follow your employer’s safety policy for

PPE’s and/or ANSI Z87.1 or local/national standards for eyewear and other personal protective equipment requirements.

To reduce the risk associated with fire or explosion:

• Do not operate the tool in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. The abrasives are able to

create sparks when working material, resulting in the ignition of the flammable dust or fumes.

• Refer to MSDS of material being worked as to potential for creating fire or explosion hazard.

To reduce the risk associated with hazardous dust ingestion or eye/skin exposure:

• Use appropriate respiratory and skin protection, or local exhaust as stated in the MSDS of the material being worked on.

To reduce the risk associated with hazardous voltage:

• Do not allow this tool to come into contact with electrical power sources as the tool is not insulated against electrical shock. .

To reduce the risk associated with skin abrasion, burns, cuts, or entrapment:

• Keep hands, hair, and clothing away from the rotating part of the tool.

• Wear suitable protective gloves while operating tool.

• Do not touch the rotating parts during operation for any reason.

• Do not force tool or use excessive force when using tool.

To reduce the risk associated with whipping or hazardous pressure-rupture:

• Ensure supply hose is oil resistant and is properly rated for required working pressure.

• Do not use tools with loose or damaged air hoses or fittings.

• Be aware that incorrectly installed hoses and fittings might unexpectedly come loose at any time and create a whipping/impact hazard.

To reduce the risk associated with fly off of abrasive product or parts:

• Use care in attaching abrasive product and mounting hardware; following the instructions to ensure that they are securely attached to the

tool before use or free-spinning.

• Never free spin the tool or otherwise allow it to be started unintentionally.

• Never point this product in the direction of yourself or another person, or start tool unintentionally.

• Never over-tighten accessory fasteners.

CAUTION!

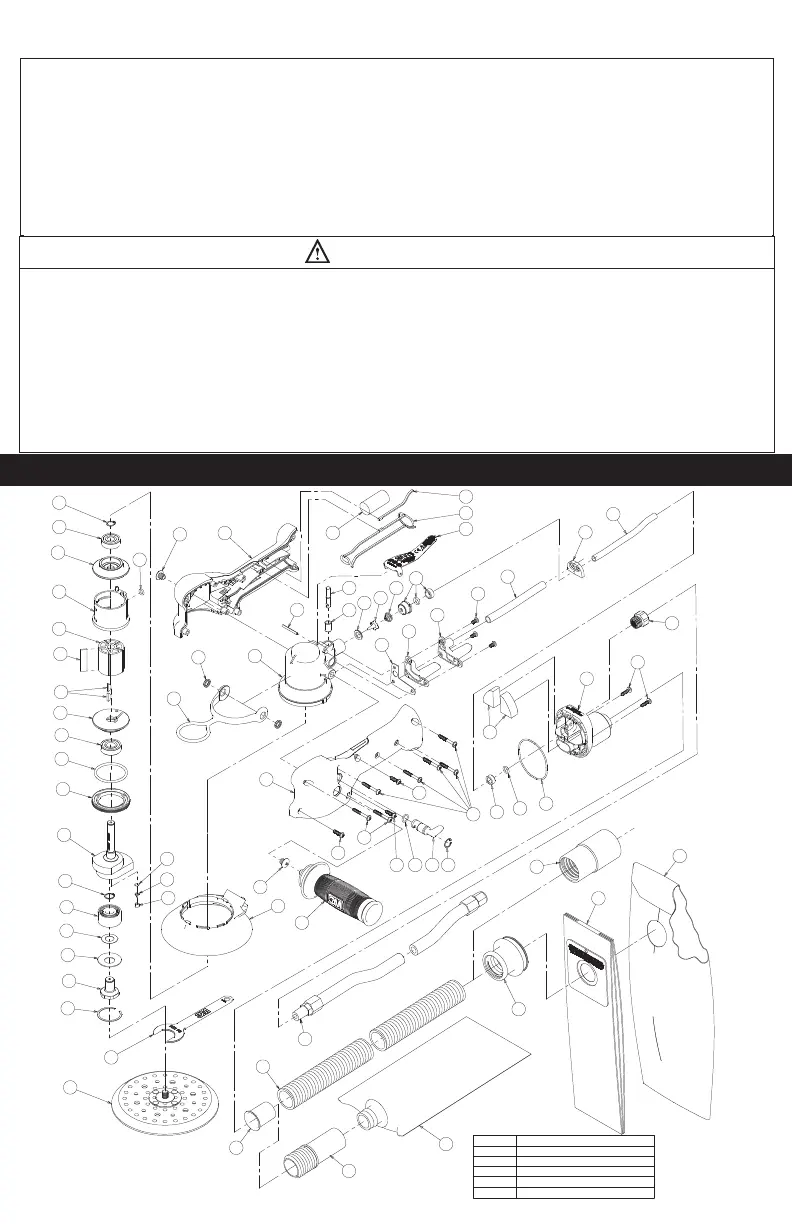

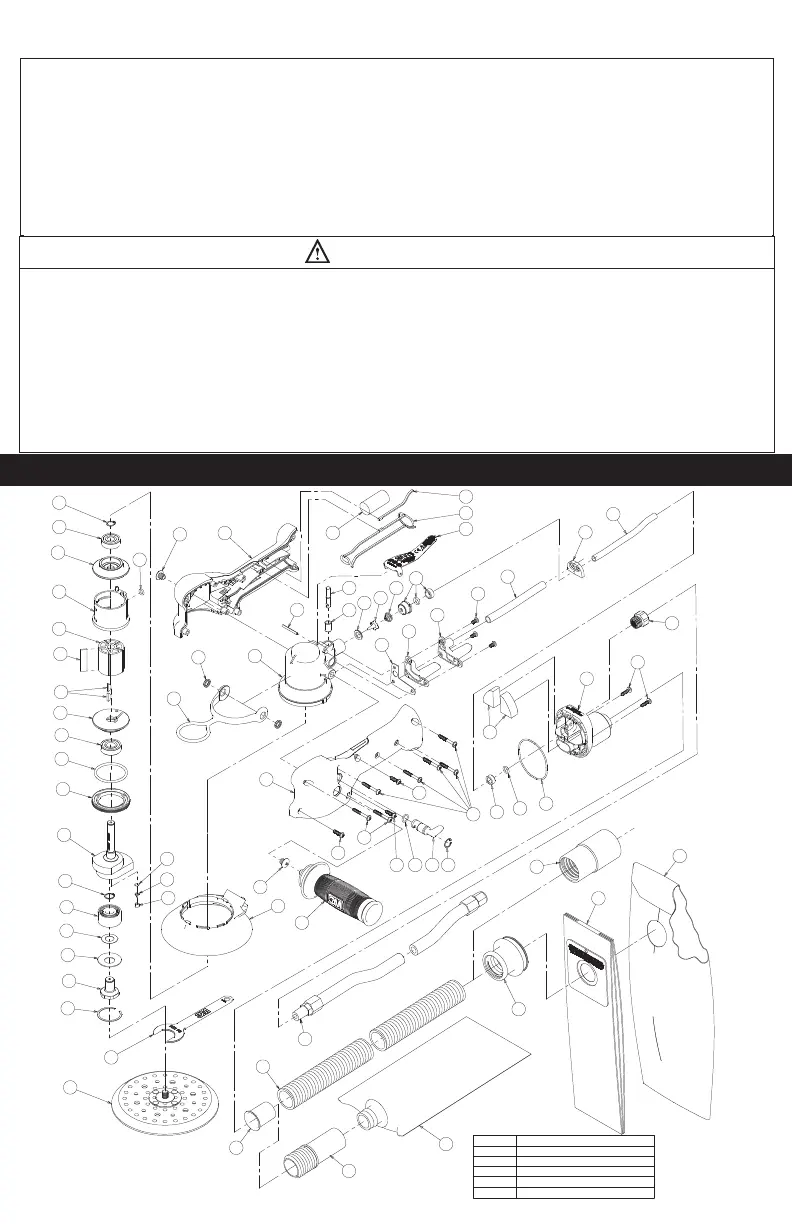

Parts Page

69

63

64

SYSTEM

VACUUM

FOR CENTRAL

TO VACUUM

62

68

67

1

2

56

3

4

57

58

5

6

7

9

10

11

12

13

17

16

15

14

18

19

20

21

22

23

24

25

26

27

28

29

30

32

31

33

34

70

59

52

8

41

42

43

44

46

45

35

36

47

48

37

38

25

49

39

51

66

51 53

54

55

51

40

60

61

50

52

51

65

ENG APP / DATE

CKD BY / DATE

PERMISSION OF X'POL E PRECISION TOOLS INC. IS P ROHIBITED.

STD TOL

0.05

TOOLS INC.

NA

PROPERTY OF X'PO LE PRECISION TOOLS INC. ANY REPRO-

SEE BOM

11/21/08

11/21/08

PWH

DUCTION IN PART OR AS A W HOLE WITHOUT THE WRITT EN

.XX +/-

XPD0056

ANGLES +/-

0.1

RAG

NA

XX/XX +/-

0.5°

X'POLE

PRECISION

P/N

TITLE

DRWN BY / DATE

MATERIAL

PROPRIETARY AND CONFIDENTIAL

.X +/-

THE INFORMATION CO NTAINED IN THIS DRAWING IS T HE SOLE

.XXX +/-

3M 6 in. (150 mm) 12,000 RPM

TwoHAND™ ROS PARTS PA GE

REVISION RECORD

R DESCRIPTION / DATE

A

-RELEASE FOR PRODUCTIO N

RAG 11/21/08 PWH 11/21/08

B

-ITEM 51: P/N XPC0210 WAS X PB0454

-XPA1488 AND XPA1490 WERE N OT

REMOVED

-XPA1485, XPA0033, XPA0027, XP B0092 AND

XPB0123 WERE NOT ADDED

RAG 02/06/09 PWH 02/07/09

C

-ITEM 13: XPB0189, XPB0205, XPB 0206, AND

XPB0207 WERE NOT REMOVE D

-ITEM 30: XPA2074 WAS NOT R EMOVED

-ITEM 48: XPA2173 WAS NOT R EMOVED

-ITEM 49: XPA2172 WAS NOT R EMOVED

-ITEM 60: XPA1962 WAS NOT R EMOVED

-TORQUE SETTINGS CHART: 51 WAS 52,

52 WAS 53, AND 61 WAS 63

RAG 02/19/09 MDR 02/20/09

D

-ITEM 66: XPA1782 WAS XPA00 33

-ITEM 67: XPA0027 WAS NOT R EMOVED

-ITEMS 67 THRU 70: ITEM NU MBERS DID

NOT DECREASE BY ONE

RAG 02/23/09 MDR 02/23/09

1

VACUUM BAG FOR 3M

XPA1434

70

1

VACUUM BAG INSERTXPC0109

69

1

1 in. DOUBLE BAG VACUUM FITTING

XPB0123

68

Y

T

Q

N

O

IT

P

I

RC

S

E

DN

/

P

T

I

1

GN

IR

G

N

I

N

I

ATE

RLA

NRETXE

04

00APX1

1

S

DL

EI

H

S

2

-

G

N

I

R

A

E

B

8

X

6

2

X

01

120

0APX2

1

ETALPDN

E

RAE

R

7

1

00BPX

3

1

Y

L

BM

E

S

SA

R

ED

N

I

LY

C

mm

0

.63

X

m

m

0

.

0

5

Ø

144

0

APX

4

1

GN

IR

-

O

mm0

.

2

x

m

m

5

2

4

0

0

A

PX

5

1

RO

TORDE

N

IH

CAMRO

T

OM

mm6

3

x

mm0.0

5

Ø

8

11

0B

PX6

5

R

O

T

O

Mm

m

0

.6

3

xm

m

0

.

0

5Ø

R

O

F

E

N

A

V

5

4

4

0

APX7

2

Y

E

K

FFURDO

OW

m

m3

1

x

m

m3

1

4

0

0A

P

X8

1E

T

A

LP

D

NE

TN

O

R

F

6

1

0

0

B

PX9

1

S

D

LE

IH

S

2-

G

NI

RA

E

B

8

X

8

2

X

2

1

91

0

0

AP

X01

1GNIR

-

Om

m

1

.

3

xm

m

4

.

9

3

5

4

0

0

A

P

X1

1

1

G

N

I

RK

C

O

L

10

0

0

A

PX2

1

13 XPB0187

TwoHAND 150 x 5.0 mm (6 x 3/16 in.) ORBIT ROS AirSHIELD™ SHAFT

BALANCER

1

13 XPB0188

TwoHAND 150 X 10 mm (6 x 3/8 in.) ORBIT ROS AirSHIELD™ SHAFT

BALANCER

1

1

R

ET

L

IF22

1

0

AP

X4

1

1

E

V

L

AV

KC

E

H

C

L

L

I

B

KC

U

D

1

210A

P

X5

1

1

RE

N

IA

TE

R

EVL

A

V

021

0APX61

1G

N

IRG

N

IN

I

A

TE

R

)

.

ni

2

3

/

5

1(m

m

9

.

1

1

0

9

0

0

A

P

X7

1

18 XPA0751 12 x 32 x 15.9 DOUBLE ROW ANGULAR CONTACT BEARING - 1 SEAL 1

1KHT2

.

0

x

D

O

0

.22

xDI

1.21

R

ECAP

S

767

1APX91

1

R

E

H

S

A

W

E

LL

I

V

E

L

L

E

B

4

2

01

A

P

X02

1

E

LD

N

I

PS

8

02

0B

P

X1

2

1

G

NI

RG

NI

N

I

A

T

E

R

5

20

1

A

P

X2

2

1DE

R

584

S

MP

-

M

3

RO

F

HC

N

E

R

W

DA

P

m

m

42

77

7

1AP

X3

2

24 NA 1 Pad Supplied With Each Tool (Type Determined By Model) 1

2DE

R

5

84

S

MP

-

G

UL

P

D

ED

A

E

R

H

T

8

M

559

1

AP

X52

1

G

N

IS

U

O

H

M

UU

C

A

V

M

3

H

R

m

m

0.

6

3

983

0

BP

X62

1

)

seni

h

ca

M

VC

&

VN

(

TRES

N

I

RE

LFFU

M

2

300APX72

1

)se

n

ihcaMVC&VN

(L

AESG

N

I

S

UO

HPOT812

1

A

PX8

2

1

L

AE

SG

NIS

U

OH

RO

T

O

Mmm0.

6

3

0

920B

P

X9

2

30 XPA2075 3M ROS 12,000 RPM 5.0 mm (3/16 in.) ORBIT THROTTLE LEVER - TwoHAND 1

30 XPA2076 3M ROS 12,000 RPM 10.0 mm (3/8 in.) ORBIT THROTTLE LEVER - TwoHAND 1

T

P

O

C

5

8

4SMP-R

EGN

A

H

D

NAH

owT4

5

91

AP

X1

3

2

G

N

I

R

R

E

CA

P

S

5

68

1

A

PX2

3

33 XPB0356

36.0 mm DIE-CAST MACHINE MO

TOR HOUSING W/SIDE HANDLE

MOUNTING STUDS

1

1

N

I

P

G

N

I

R

PSR

EDN

I

LYC4

0

0

0

AP

X4

3

1YLBMESSA

ME

TS

EVLAV

556

0APX53

1

E

V

E

E

L

SE

V

LA

V

5

1

0

0

A

P

X6

3

1

T

A

E

SE

V

L

A

V

9

0

0

0

A

P

X7

3

1E

VL

A

V

7

0

0

0A

P

X8

3

1

G

N

I

R

P

S

E

V

L

A

V

4

1

0

0

A

P

X

9

3

1Y

L

B

M

ES

S

A

L

A

E

S

E

NI

L

R

IA

0

3

70

A

P

X04

1

T

E

K

S

A

G

T

SU

A

H

X

E

0

0

5

0

A

P

X1

4

1EL

Z

Z

ON

T

S

U

A

H

X

E

V

G

S

R

O

T

O

Mm

m

0

.6

3

1

81

0

B

PX2

4

1

E

L

Z

Z

O

N

T

S

U

A

H

XE

V

C/

V

N

2

8

1

0

B

PX3

4

3

W

E

RCS

P

AC

D

AE

HN

O

T

TUBTEK

C

O

S

X

EH

8

X

4M46

60

APX4

4

1

)

s

e

n

i

h

c

a

MV

C

&V

N

(P

M

A

L

CG

N

I

B

U

T

6

1

50A

P

X5

4

1

)

s

e

ni

h

c

aM

VC&

VN

(

GN

I

BU

T

T

SU

A

H

X

E

71

5

0

A

P

X

6

4

1G

N

I

B

U

T

T

E

L

N

I

1

1

5

0A

P

X7

4

1

D

E

R5

8

4S

M

P

-DU

O

RH

SE

L

O

H

-

I

T

L

U

M

"

6D

N

A

H

o

w

T

1

2

1

2A

P

X8

4

T

PO

E

LD

N

A

H

E

D

IS

M

3

0

691a

p

x

94

1

EL

OHEL

D

NAHEDIS/W

G

NISU

O

H

Y

ER

G

H

Lmm

0

.

63

0

12

0

C

P

X0

5

5

K

CA

L

Bm

m5

1

X0.4

MX

R

O

TD

A

E

HNO

T

T

U

B,

W

E

R

C

S

8

9

3

1

A

P

X1

5

7

K

C

A

L

Bm

m0

3

X0

.

4

MX

R

O

TD

A

E

H

NO

T

T

U

B

,

W

E

R

C

S

0

3

4

1

A

P

X2

5

1GN

I

R

-Om

m5

.

1

xm

m9

340

0AP

X35

1DER584

S

MP-

LORTNOC

DEEPS

DNAHowT

3591aPX45

1

GNIR

G

N

I

NIATER

LA

N

RE

T

N

I

9

300APX55

1

G

NIRE

V

I

T

P

AC

T

E

L

NI

0

1

5

0A

P

X6

5

1

G

NIR

-

Om

m

8

7.

1

xmm

6

.

7

9

0

5

0

A

P

X7

5

1)

s

e

n

i

h

c

a

MV

C

&V

N

(G

N

I

R

-

O

8

260A

P

X8

5

2)

se

n

i

hc

a

MVC&

V

N

(

R

E

L

F

F

U

M

6

7

7

0

A

P

X9

5

60 XPA1965 INLET/EXHAUST END CAP ASSEMBLY FOR SGV AND CV MACHINES 1

1Y

LB

M

E

SS

AG

NIH

S

U

BT

E

L

N

I

T

P

N8

1

-

4/

1

3

100

A

P

X1

6

1

)

s

e

n

i

h

c

aM

V

G

S

(

™

D

N

A

H

o

w

T-

LA

E

SE

S

O

H

)m

m8

2

(.

ni1

3

2

6

0

A

P

X

2

6

63 XPA1669 3M™ FILTER BAG ADAPTOR, 1in EXT HOSE THREAD X 1in OD 1

1

)

n

i

2

1

X

5(GA

B

R

E

T

LI

F

G

N

I

D

N

ASN

A

EL

C™

M

3

8

66

1

A

PX4

6

65 XPA1485 Ø 1 in. x 6 ft. VA 1

D

E

R

C

5

8

4

S

M

P

-E

S

O

H

M

U

U

C

66 XPA1782 Ø 3/8 in x 4 ft AIR LINE WITH Ø 1/4 in COMPRESSION FITTINGS 1

67 XPB0092 HOSE END ADAPTER - 1 in./28 mm HOSE THREAD X 1 1/2 in. O.D. 1

ITEM NO. TORQUE SETTINGS in.-lbs (N-m)

12 55 - 65 (6.2 - 7.3)

44 21 - 30 (2.4 - 3.4)

51 27 - 30 (3.0 - 3.4)

52 29 - 33 (3.3 - 3.7)

61 60 - 72 (6.8 - 8.1)

Loading...

Loading...