12

3M™ Bair Hugger™ Warming Unit Model 775 – Service Manual

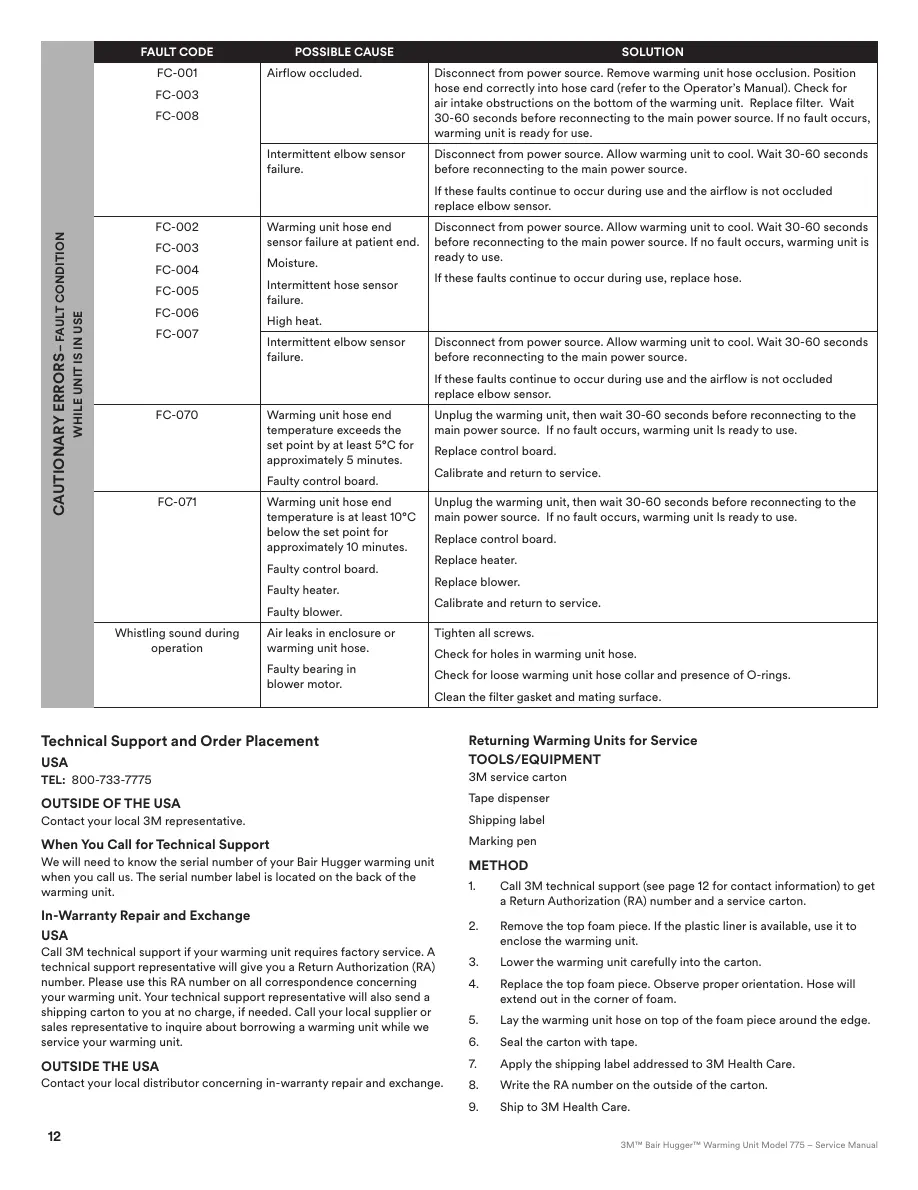

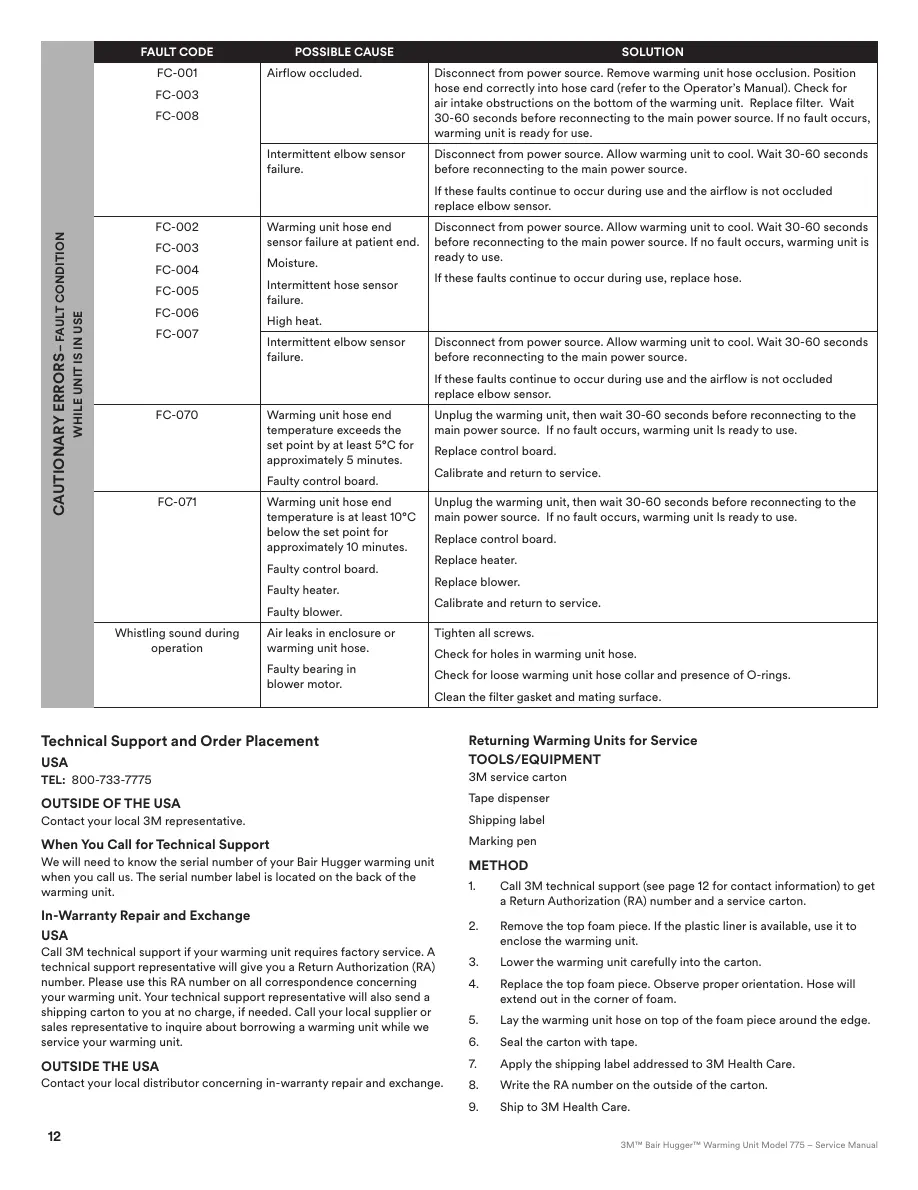

CAUTIONARY ERRORS–FAULT CONDITION

WHILE UNIT IS IN USE

FAULT CODE POSSIBLE CAUSE SOLUTION

FC-001

FC-003

FC-008

Airflow occluded. Disconnect from power source. Remove warming unit hose occlusion. Position

hose end correctly into hose card (refer to the Operator’s Manual). Check for

air intake obstructions on the bottom of the warming unit. Replace filter. Wait

30-60 seconds before reconnecting to the main power source. If no fault occurs,

warming unit is ready for use.

Intermittent elbow sensor

failure.

Disconnect from power source. Allow warming unit to cool. Wait 30-60 seconds

before reconnecting to the main power source.

If these faults continue to occur during use and the airflow is not occluded

replace elbow sensor.

FC-002

FC-003

FC-004

FC-005

FC-006

FC-007

Warming unit hose end

sensor failure at patient end.

Moisture.

Intermittent hose sensor

failure.

High heat.

Disconnect from power source. Allow warming unit to cool. Wait 30-60 seconds

before reconnecting to the main power source. If no fault occurs, warming unit is

ready to use.

If these faults continue to occur during use, replace hose.

Intermittent elbow sensor

failure.

Disconnect from power source. Allow warming unit to cool. Wait 30-60 seconds

before reconnecting to the main power source.

If these faults continue to occur during use and the airflow is not occluded

replace elbow sensor.

FC-070 Warming unit hose end

temperature exceeds the

set point by at least 5°C for

approximately 5 minutes.

Faulty control board.

Unplug the warming unit, then wait 30-60 seconds before reconnecting to the

main power source. If no fault occurs, warming unit Is ready to use.

Replace control board.

Calibrate and return to service.

FC-071 Warming unit hose end

temperature is at least 10°C

below the set point for

approximately 10 minutes.

Faulty control board.

Faulty heater.

Faulty blower.

Unplug the warming unit, then wait 30-60 seconds before reconnecting to the

main power source. If no fault occurs, warming unit Is ready to use.

Replace control board.

Replace heater.

Replace blower.

Calibrate and return to service.

Whistling sound during

operation

Air leaks in enclosure or

warming unit hose.

Faulty bearing in

blower motor.

Tighten all screws.

Check for holes in warming unit hose.

Check for loose warming unit hose collar and presence of O-rings.

Clean the filter gasket and mating surface.

Technical Support and OrderPlacement

USA

TEL: 800-733-7775

OUTSIDE OF THE USA

Contact your local 3Mrepresentative.

When You Call for TechnicalSupport

We will need to know the serial number of your BairHugger warming unit

when you call us. The serial number label is located on the back of the

warmingunit.

In‑Warranty Repair andExchange

USA

Call 3M technical support if your warming unit requires factory service. A

technical support representative will give you a Return Authorization (RA)

number. Please use this RA number on all correspondence concerning

your warming unit. Your technical support representative will also send a

shipping carton to you at no charge, if needed. Call your local supplier or

sales representative to inquire about borrowing a warming unit while we

service your warmingunit.

OUTSIDE THEUSA

Contact your local distributor concerning in-warranty repair andexchange.

Returning Warming Units forService

TOOLS/EQUIPMENT

3M servicecarton

Tape dispenser

Shippinglabel

Markingpen

METHOD

1. Call 3M technical support (see page 12for contact information) to get

a Return Authorization (RA) number and a service carton.

2. Remove the top foam piece. If the plastic liner is available, use it to

enclose the warmingunit.

3. Lower the warming unit carefully into thecarton.

4. Replace the top foam piece. Observe proper orientation. Hose will

extend out in the corner of foam.

5. Lay the warming unit hose on top of the foam piece around theedge.

6. Seal the carton withtape.

7. Apply the shipping label addressed to 3M HealthCare.

8. Write the RA number on the outside of the carton.

9. Ship to 3M HealthCare.

13

GB / 34-8718-8817-7

Specifications

Guidance and manufacturer’s declaration – electromagnetic emissions

The Model 775warming unit is intended for use in the electromagnetic environment specifiedbelow. The customer or the user of the Model

775 warming unit should assure that it is used in such an environment.

Emissions test Compliance Electromagnetic environment ‑guidance

RFemissions

CISPR 11

Group 1 The Model 775 warming unit uses RF energy only for its internal function. Therefore, its RF emissions are

very low and are not likely to cause any interference in nearby electronicequipment.

RFemissions

CISPR 11

Class B The Model 775warming unit is suitable for use in all establishments, including domestic establishments

and those directly connected to the public low-voltage power supply network that supplies buildings

used for domesticpurposes.

Harmonicemissions

IEC 61000-3-2

Class A

Voltagefluctuations/

Flickeremissions

IEC 61000-3-3

Complies

Guidance and manufacturer’s declaration – electromagnetic immunity

The Model 775warming unit is intended for use in the electromagnetic environment specifiedbelow. The customer or the user of the Model

775 warming unit should assure that it is used in such an environment.

Immunity Test IEC 60601 test level Compliance level Electromagnetic environment ‑guidance

Electrostatic

discharge(ESD)

IEC 61000-4-2

±6kV contact

±8kV air

±6kV contact

±8kV air

Floors should be wood, concrete or ceramic tile. If floors are covered with

synthetic material, the relative humidity should be at least 30%.

Electrical

fasttransient/burst

IEC 61000-4-4

±2kV for power

supplylines

±1 kV for input/output

lines

±2kV for power

supplylines

±1 kV for input/output

lines

Mains power quality should be that of a typical commercial or

hospital environment.

Surge

IEC 61000-4-5

±1 kV line toline

±2kV line(s) to earth

±1 kV line toline

±2kV line(s) to earth

Mains power quality should be that of a typical commercial or

hospital environment.

Voltage dips, short

interruptions and

voltage variations

on power supply

input lines

IEC 61000-4-11

<5% U

T

(>95% dip in U

T

)

for 0,5cycle

40% U

T

(60% dip in U

T

)

for 5cycles

70% U

T

(30% dip in U

T

)

for 25cycles

<5% U

T

(>95% dip in U

T

)

for 5sec

<5% U

T

(>95% dip in U

T

)

for 0,5cycle

40% U

T

(60% dip in U

T

)

for 5 cycles

70% U

T

(30% dip in U

T

)

for 25cycles

<5% U

T

(>95% dip in U

T

)

for 5sec

Mains power quality should be that of a typical commercial or hospital

environment. If the user of the Model 775warming unit requires continued

operation during power mains interruptions, it is recommended that the

Model 775warming unit be powered from an uninterruptible power supply

or a battery.

Power frequency

(50/60Hz)

magneticfield

IEC 61000-4-8

3 A/m 3 A/m Power frequency magnetic fields should be at levels characteristic of a

typical location in a typical commercial or hospital environment.

NOTE U

T

is the a.c. mains voltage prior to application of the test level.

Loading...

Loading...