Water Leakage Detector

Type : WL-AD-2002-A

Instruction manual

For safety, please read this manual before

using this detector carefully.

・Do not disassemble the detector, in order to

prevent becoming an electric shock and a fire.

・Shut off the power before wiring, in order to

prevent becoming an electric shock to touch

the power terminal.

IMPORTANT NOTICE

・Please purchase PF113A type sockets, 11 pins.

・The detector is designed to use for indoor only.

・ Don’t install the detector in the place as

follows.

- Where detector is watered

- High temperature and high humidity

- Where temperature change is sharp

- Where vibration is intense

- Where an electric noise is intense

- Any hazardous location where the likelihood

of flammable or combustible or explosive

concentrations exists.

・The detector can detect a liquid that is electric

only.

・ The detector is designed in combination

with a sensor that is made by SUMITOMO

3M Ltd.

・B-3P and S-1F type sensor should be used

within 100 meter per 1 detector. On the other

hand, S-1FP type sensor is should be used

within 50 meter.

・The maximum total length of the sensor and

extension wire are 150m per 1 detector.

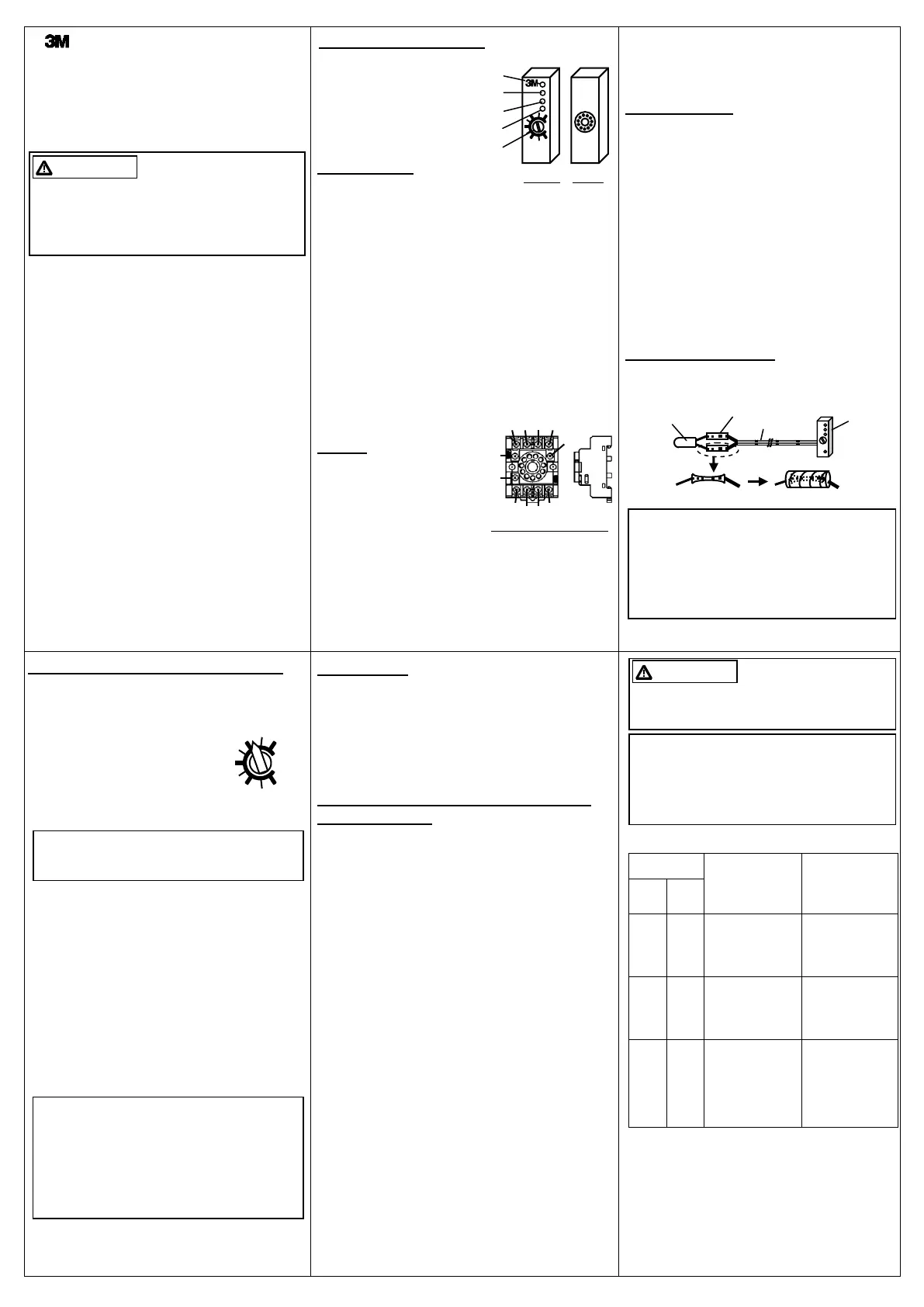

Explanation of Detector

Specifications

Number of detect 1 point

Power voltage AC100-110V±10V or

(50/60Hz) AC200-220V±20V

Sensitivity level 25k to 560k ohm

100k ohm (Initial-setting)

Voltage to sensor Approx. 9V

Current of Sensor shortage Less than 1mA

Output signal “C” contact (No-Voltage)

Contact rating 3A/125VAC,3A/30VDC

Power consumption Less than 2W

Operating temp range -15 to 45 Centigrade degree

Max operating moisture 90% RH (No dew drop)

Dimension 90×35×90 (mm)

Weight 180g

Suitable socket PF113A type sockets, 11 pins

Accessories Terminal kit

Wiring

Connect each wire, which are

Power, Sensor and Output

signal, to suitable terminal of

the socket as follows.

1) Power PF113A type sockets

- AC110V: No. 2 and 9 terminal

- AC220V: No. 3 and 9 terminal

2) Sensor: No. 4 and 5 terminal

3) Output signal of Sensor short & Water warning

- “a” contact: No. 10 and 11 terminal

- “b” contact: No. 10 and 1 terminal

4) Output signal of sensor breaking warning

- “a” contact: No. 6 and 7 terminal

- “b” contact: No. 6 and 8 terminal

Operation test:

Switch on the power supply after inserting the

detector in the socket certainly, and check the

following operation.

In 2 and 3 operations, check the work of an

outside alarm when the output signal is

connected to it.

1) Power lamp lights up.

2) Sensor Short warning lamp lights up, when

the electrodes or terminals of a sensor are

shorted each other over 4 sec.

3) Sensor Short warning lamp puts out within 4

sec and Sensor Open warning lamp lights up,

when the electrodes or terminals of a sensor

are opened.

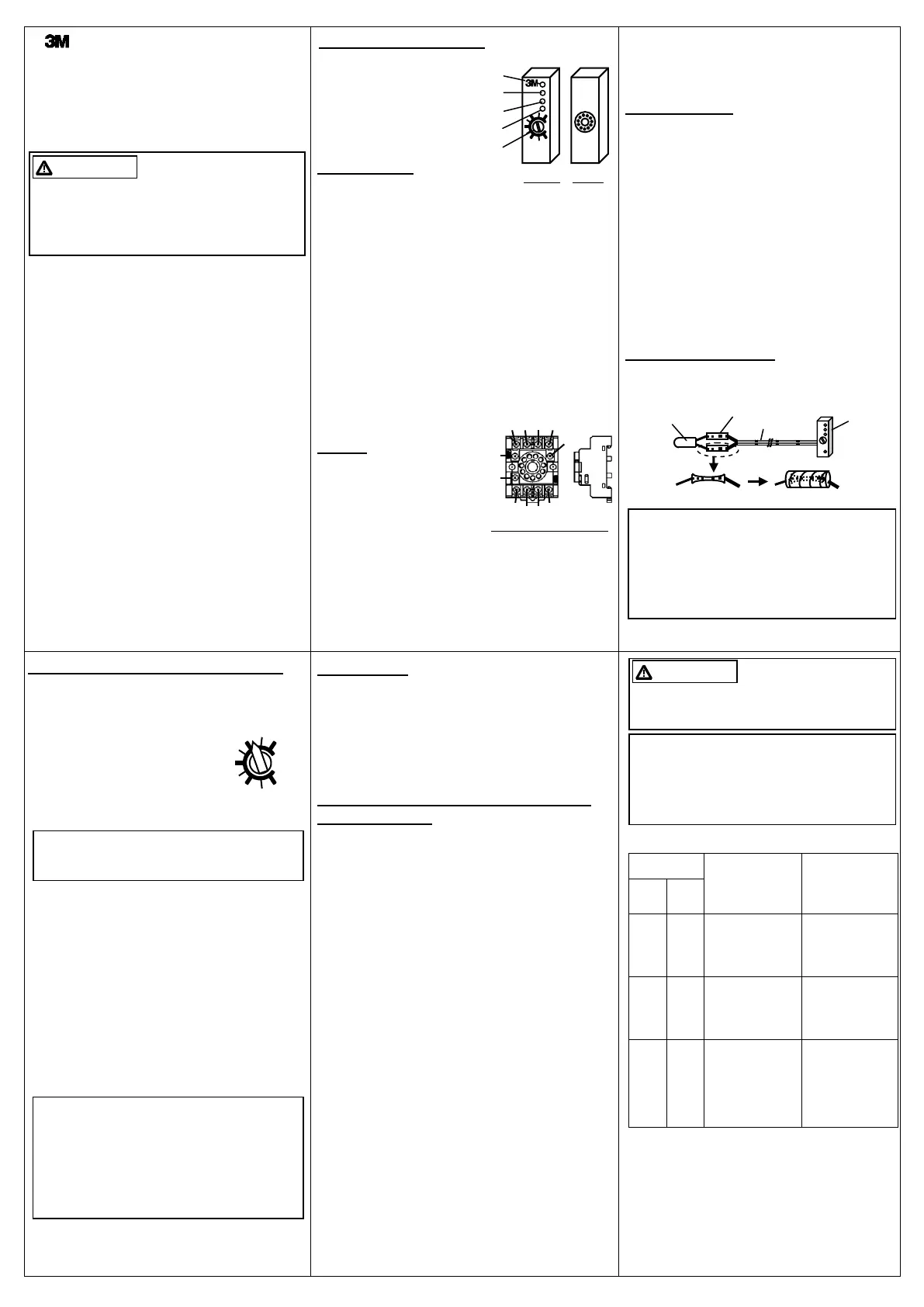

Terminal resister kit:

Connect the Terminal Kit at an end of sensor

by making sticking-by-pressure with a sleeve.

Next, roll a tape around the sleeve to insulate.

NOTICE:

・If the Terminal Kit isn’t connected, Sensor

Open lamp lights up. And also, Sensor

breaking warning function doesn’t work.

・ Although Terminal kit is connected,

sensor or jumper wire is disconnected or

broken when Sensor Open lamp lights up.

Adjust sensitivity and Operation test

Detection sensitivity can be changed according

to the characteristic of a sensor, or a state of an

installation place.

After sensor is installed, Water Alarm operation

should be checked to work to drop

water, which is expected to leak,

on a sensor in order that the

sensitivity may set up correctly.

And also check the outside alarm

works or not, if it is connected to

Output signal.

NOTICE:

After the operation test, wipe the sensor and

the floor dry completely by cloth etc..

<Standard of sensitivity to set up>

1) B-3P or S-1F or PS-1R type Sensor is installed

on a floor, when detecting the liquid of high

electric conduction equivalent like tap water.

--- Set volume between 0 to 2

2) S-1F type Sensor is installed on a floor, when

detecting the liquid of low electric conduction

equivalent like pure water.

--- Set volume between 2 to 7

3) S-1FP type Sensor is installed on a pipe, when

detecting the liquid of high electric conduction

equivalent like tap water.

--- Set volume between 2 to 4

NOTICE:

・Check the detector’s operation with dropping

water, which is expected to leak, after the

detection sensitivity setup.

・ Don’t set the detection sensitivity under

“1.5” when S-1FP type sensor is installed on

a pipe, because the sensitivity would be too

low to detect a leaked water.

Maintenance

Water Alarm operation should be checked to work to

drop a water, or the electrodes or terminals of a

sensor are shorted each other.

And also, check to see such as corrosion and dirt in a

sensor. Especially, in S-1FP, when the sensor is

remarkably dirty with dust etc., the sensor should be

exchanged to new one.

Method to take measure when Water

alarm comes out

When Water alarm comes out, take a cause and a

measure in the following procedure.

If a leakage-of-water alarm comes out,

1) Water is detected by the sensor or not, to check

visually.

- When water is detected, the cause and the

measure should be taken.

- When water isn’t detected, go to No.2 step.

2) The sensitivity adjust volume is turned to “0”, to

check the alarm is stop or not.

- When the alarm is off, go to step No.3.

- When the alarm is continued, go to step No.4.

3) When volume is set as the minimum of the above

"Standard of sensitivity setup", it checks whether

the alarm comes out.

- When the alarm comes out, go to step No.4.

- When the alarm is off, the sensitivity is set up.

However, Water Alarm operation should be

checked to work to drop water, which is

expected to leak, on a sensor.

4) After the power is off and the detector is removed

from the socket, the insulation resistance between

wires of the sensor is measured with an insulation

tester, which voltage is DC100 - 250V, within in 5

seconds. And also, it is measured with a tester,

which is DC1.5V.

Shut off the power before wiring, in order to

prevent becoming an electric shock to touch

the power terminal.

NOTICE:

・Remove the detector from the socket before

measuring the insulation resistance , in

order to avoid break down of the detector.

・Use an insulation tester which voltage is

under DC250V.

<Result of measure>

The sensor detect

the water of slight

quantity, such as

dew condensation

(Note)

- Dry the sensor

- Water is wiped

off

- Wait until

sensor dry

The cause by

which water

leaked is studied

and measures

should be taken.

- False alarm by

outside noise

- Detector is out

of order

- Detector is

broken

- etc

Note) Since concrete has not got dry a few week

after completion of the building, even if

dew condensation water does not appear, it

may have dewed actually.

1: Sensor Open warning lamp

2: Sensor Short warning lamp

3: Water warning lamp

4: Power lamp

5: Sensitivity adjust volume

6: Terminal (11 pins)

Sensitivity

adjust volume

Loading...

Loading...