Do you have a question about the ABB CEMcaptain GAA610-M and is the answer not in the manual?

The ABB CEMcaptain GAA610-M is an advanced emission gas monitoring system designed for continuous measurement of exhaust gases from marine diesel engines. It primarily monitors SO2 and CO2 emissions, reporting the ratio as specified by the IMO (International Maritime Organization), and can also be used for continuous monitoring of CO if required. The system is based on ABB's proven NDIR (Non-Dispersive Infrared) measurement technology, specifically utilizing the AO2020-Uras26 gas analyzer module.

The GAA610-M operates as a multi-component analyzer system, providing real-time data on relevant pollutants. It ensures compliance of vessels with low emission limits in Emission Control Areas (ECA zones) and global limits. The measurement data can also be used to control the exhaust gas cleaning system (scrubber) on board.

The system extracts sample gas from the exhaust gas stream. Since the raw sample gas cannot be processed directly due to excessive dust, temperature, dew point, or interfering components, additional devices are integrated for sample treatment. These include a sampling probe, a heated sample gas line, a sample gas cooler, filters, and a pump. These components ensure that the sample gas meets the entry conditions of the analyzer, providing accurate measurement results regardless of process and local conditions.

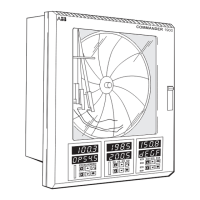

The GAA610-M is a complete turn-key solution, integrating all sample conditioning components and the gas analyzer into a single cabinet. Available options include an air conditioning unit for operation at ambient temperatures from 5 to 55 °C (41 to 131 °F), with higher temperatures available on request. Dual sampling for simultaneous measurement at two different locations is also an option.

The system's robust and simple design, coupled with innovative digital features, aims to reduce maintenance hassles and increase uptime during ship operation. It is proven for use on board by major classification societies and complies with Marpol Annex IV requirements and NOx Technical Code 2008.

| Brand | ABB |

|---|---|

| Model | CEMcaptain GAA610-M |

| Category | Measuring Instruments |

| Language | English |

Loading...

Loading...