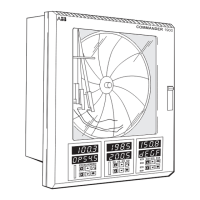

Do you have a question about the ABB CoriolisMaster FCB450 and is the answer not in the manual?

Identifies DANGER, WARNING, CAUTION, and NOTICE signal words for immediate hazards.

Details device configurations, ATEX/IECEx, and cFMus markings for explosive atmospheres.

Outlines electrical specifications and protection types for different zones/divisions.

Covers installation, housing, cable entries, and safety for hazardous areas.

Covers site selection, mounting, seals, pressure loss, and supports for proper installation.

Emphasizes safety during electrical work and details power supply and cable connection requirements.

Details pin assignments for inputs/outputs, signal cables, and digital communication protocols.

Details DIP switch configurations, write protection, parameterization methods, and software installation.

Details safety precautions and procedures for replacing components like fuses, LCD indicators, and frontend boards.

| Measurement Principle | Coriolis |

|---|---|

| Type | Mass flowmeter |

| Accuracy | ±0.1% of rate |

| Repeatability | ±0.05% of rate |

| Process Pressure | up to 100 bar |

| Material | Stainless steel |

| Protection Class | Ex d, Ex ia |

| Process connection | Flange, Thread, Hygienic |

| Output | 4-20 mA, pulse, frequency |

| Power Supply | 24 V DC, 100-240 V AC |

| Enclosure Protection | IP67 |

| Approvals | ATEX, IECEx |

| Communication Protocol | HART, Modbus |

| Fluid Temperature | -50 to +200 °C |

Loading...

Loading...