Materials of Construction

Meter Body (Spool) Ceramic, 99.5% Alumina

Electrode Assemblies (wetted) Platinum

Meter Housing carbon steel, all welded construction, epoxy finish

Housing End Rings 304 sst

Electronics Housing die cast aluminum, epoxy finish, 316 sst attach-

ment screws, 1/2 NPT conduit connections, gas-

keted covers

Installation Kit includes 2 gaskets, mounting studs and nuts,

flange adaptor device(s) as required.

Exception: Sanitary TRI-CLAMP Fittings

Meter is preassembled; all mounting hardware

(studs and nuts) and flanges are stainless steel.

Gaskets are TEFLON-FEP (Virgin). Gasket

manufacturer must provide certificate of compli-

ance as proof of U.S.D.A. approval and compli-

ance with 3A Sanitary Standards, Class-I

material.

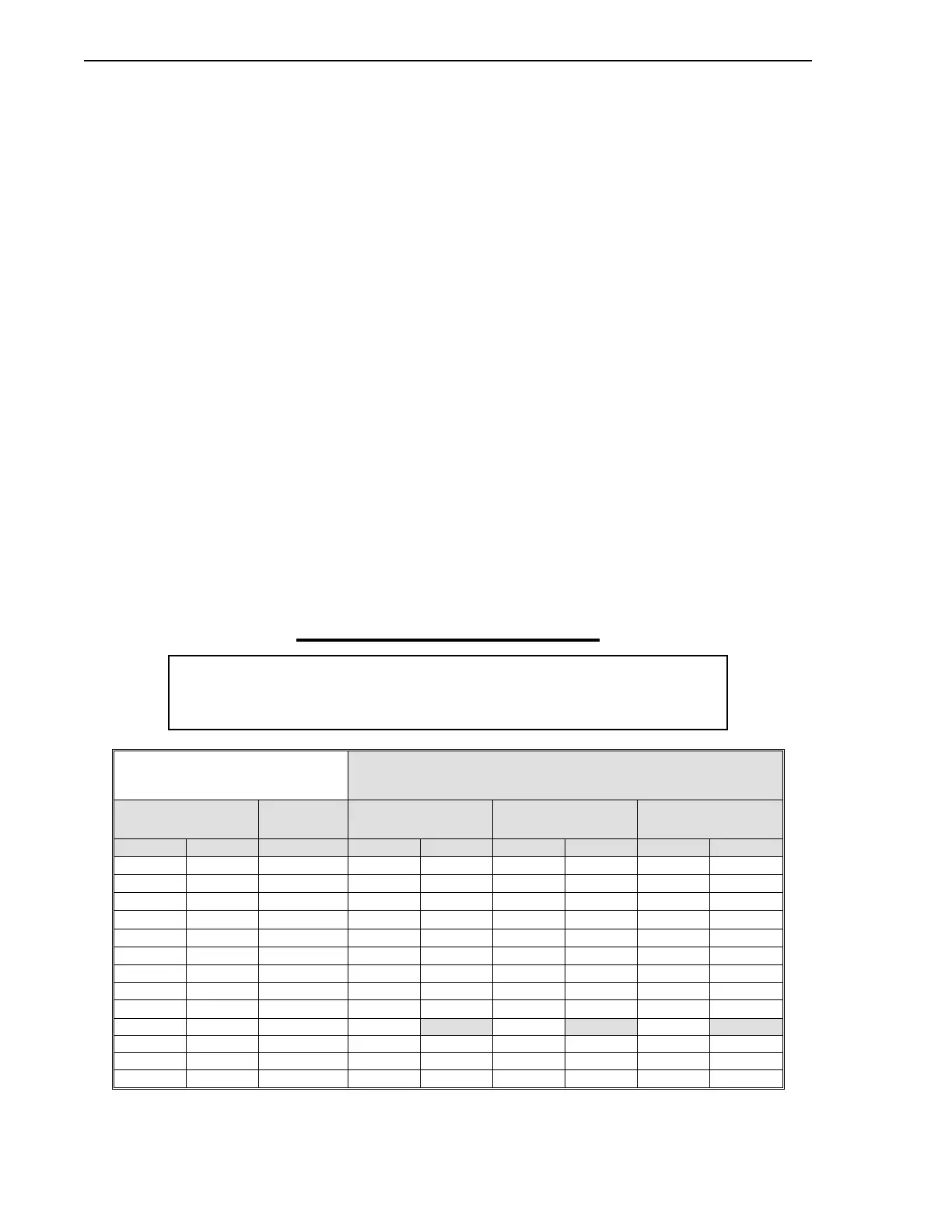

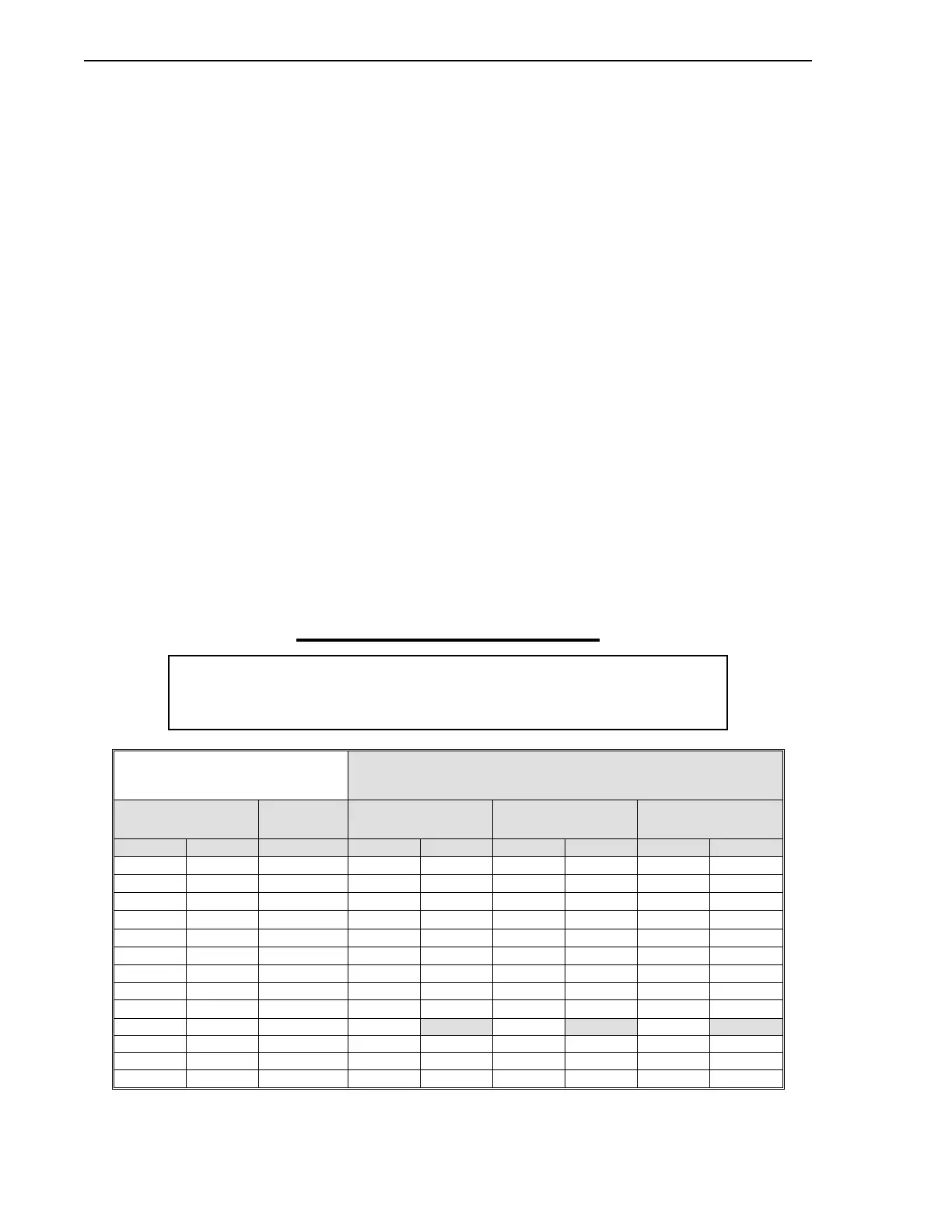

TABLE 1-1. CAL FACTOR and CAPACITY

NOTE

The CAL FACTORS given below can only be used with Model 10D1476 De-

sign Levels B,C, M, N, P & S. For Meters manufactured under design level

A, refer to the meter data tag for the appropriate factor.

Flow Ranges

0 to value tabulated

Meter Size CAL

FACTOR*

Minimum

10D1476B & C

Minimum

10D1476M, N & P

Maximum

mm inch gpm gpm lpm gpm lpm gpm lpm

1

1

⁄

25

0.1610 0.014 0.06 0.009 0.03 0.18 0.60

2

1

⁄

12

0.5368 0.048 0.20 0.027 0.10 0.54 2.00

3

1

⁄

10

1.073 0.096 0.40 0.054 0.20 1.20 4.00

4

5

⁄

32

2.147 0.192 0.80 0.108 0.40 2.40 8.00

6

1

⁄

4

5.367 0.480 2.00 0.270 1.00 6.00 20.0

10

3

⁄

8

12.08 1.08 4.50 0.605 2.25 13.5 45.0

15

1

⁄

2

26.84 2.40 10.0 1.35 5.0 30.0 100.

25 1 53.67 4.80 20.0 2.70 10.0 60.0 200.

40 1

1

⁄

2

161.0 14.4 60.0 8.10 30.0 180. 600.

m

3

/H m

3

/H m

3

/H

50 2 268.4 24.0 6.0 13.5 3.0 300. 60.

80 3 805.1 72.0 18.0 40.5 9.0 900. 180.

100 4 1073.0 96.0 24.0 53.7 12.0 1200 240.

* Flow Velocity (ft/s) = (Operating GPM x 33.33)/CAL Factor

10D1476 K-MAG MAGNETIC FLOWMETER INSTRUCTION MANUAL

1-8

Loading...

Loading...