8

KM26 | MAGNETIC LEVEL GAUGE | OI/KM26-EN REV I

Temperature

class (Ex db)

Max. process

temperature

Max. surface

temperature

T6 < 80 °C 85 °C

T5 < 95 °C 100 °C

T4 < 130 °C 135 °C

T3 <195 °C 200 °C

T2 < 295 °C 300 °C

T1 < 445 °C 450 °C

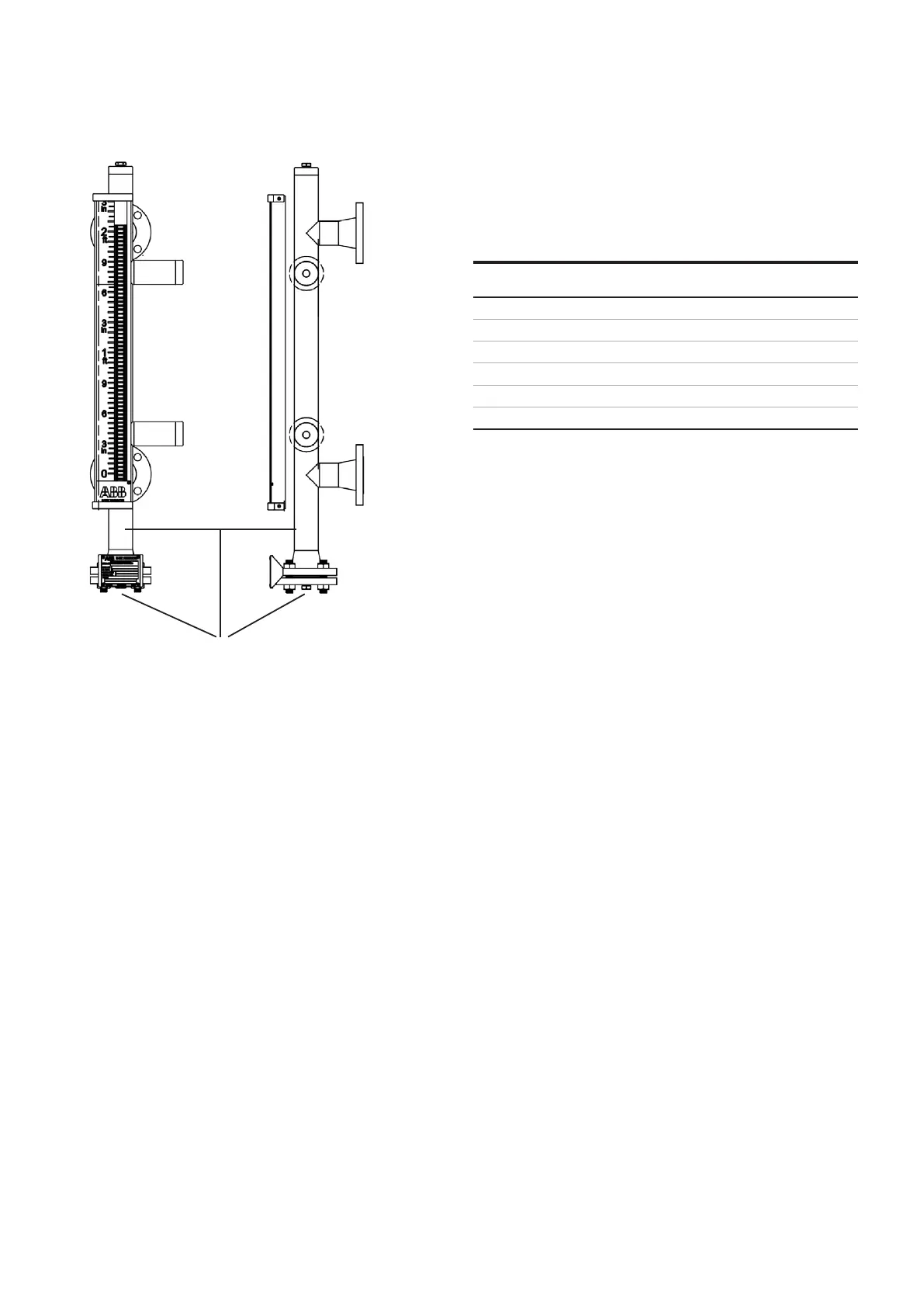

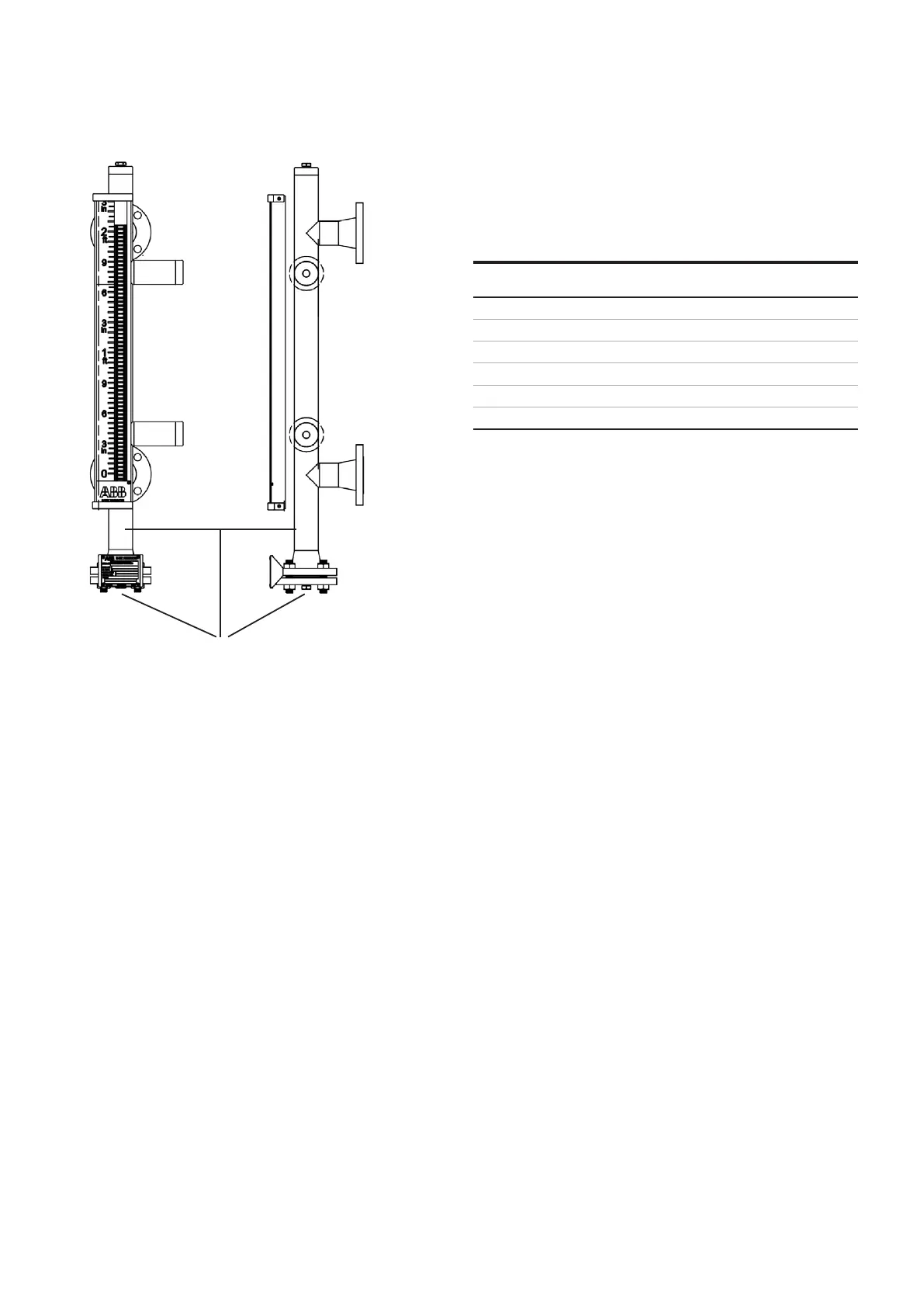

Possible grounding locations with a pipe clamp, pipe strap

or ring terminal on flange stud.

Figure 5 - Grounding locations

... 2 Safety

Temperature considerations

The KM26 is capable of operation in extreme environments.

Special consideration must be given to the components

attached to the KM26 when used at these extremes.

At high temperatures, scales, switches, and transmitters

must be protected from the adverse effects of these

temperatures on their internal components. High

temperature insulation is frequently used to raise the limits at

which these devices may operate. This insulation should not

be removed without adequate replacement. These devices

rely on proximity with the chamber to operate, therefore any

replacement insulation should not increase the separation of

the device from the float. Any additional insulation installed

should not trap unwanted heat in these devices.

At low temperatures, condensation, frosting, and freezing are

a concern. Insulation for these conditions is provided as an

option and in some cases, it is highly recommended. Special

indicator tubes are made to reduce the effects of cryogenic

chambers on the indicator. These indicator tubes require

insulation that can be provided as an option.

Recommendations for this insulation are included at the end

of this manual. Low temperatures also cause embrittlement

of some metals. Chambers and flange bolting must meet the

temperature specifications. ABB does not recommend

customer application of cryogenic insulation.

Table 1 - ATEX constructional safety temperature classfication

Temperature classification

Temperature classifications of the ATEX approved KM26 is

limited to process temperatures up to 50C below the

maximum surface temperature allowed for each of the

temperature classes as per the below table.

ATEX constructional marking

II 2 G c TX (external)

II 1 G c TX (internal)

Applicable standards: EN134653-1:2009; EN13463-5:2001

Pressure equipment directive (PED)

(97/23/CE )

Based on the order, the product shall conform to the EC

directives listed in the device specific EC declaration of

conformity. It is designed in accordance with safe engineering

pratices to meet state of the art safety requirements, has

been tested and left the factory in a condition in which they

are safe to operate.

Storage and handling information

To prevent damage to the shipping tubes and / or crates that

the level gauges are transported in, these items should not be

over-exposed to inclement weather. The KM26 magnetic level

gauge should be stored in such a manner that would not

allow the indicator tube to be immersed or submerged in any

liquid. Sufficient precautions should be taken so that the

glass or polycarbonate indicator tubes are not broken or

damaged. There are no special storage requirements for the

EC chamber themselves, but if there is a transmitter and / or

switch, the storage requirements of the transmitter and / or

switch must be met. See data sheets for specific requirement.

• after unpacking the, inspect it for damage.

• check the packaging for accessories.

• during intermediate storage or transport, only store the

level gauge in the original packaging.

• if required, storage prior to installation should be indoors

at ambient temperatures, not to exceed ambient

conditions as specified in the individual datasheet of the

accessories.

For information on permissible ambient conditions for

storage and transport, refer to the specification section of

the datasheet. Although there is no limit on the duration of

storage, the warranty conditions stipulated on the supplier’s

order of acknowledgement still applies.

Loading...

Loading...