15 Rue des Marais 44310 ST Philbert de Gd Lieu – Tel. 02 40 59 95 35 – www.acis-france.com

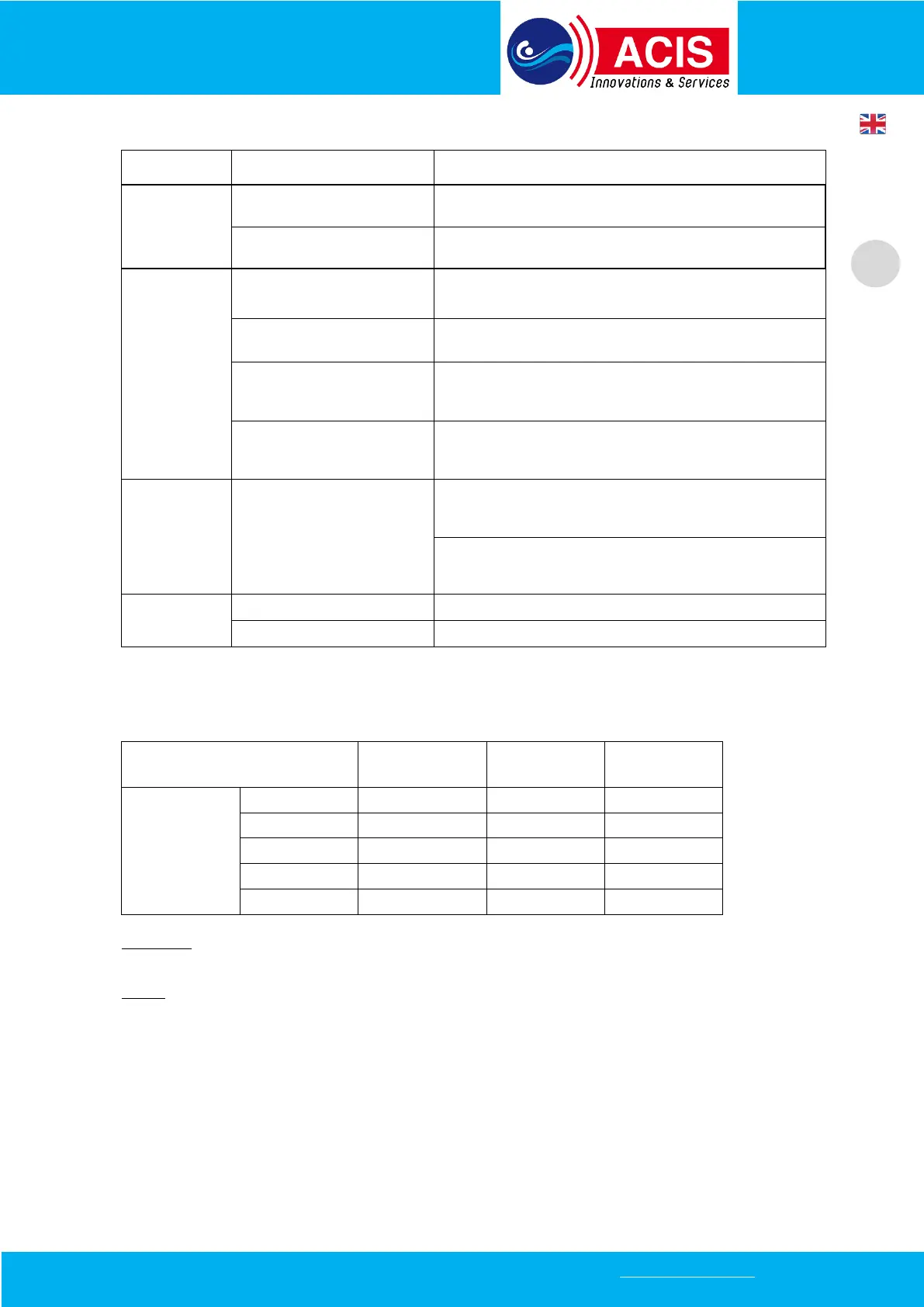

Air leak along the suction pipe

Check the condition of the couplings and seals along the suction pipe

Incorrect motor revolution direction

(three-phase motor)

Invert 2 phases on the electricity supply

Air leak along the suction pipe

Check the condition of the couplings and seals along the suction pipe

Incorrect motor revolution direction

(three-phase motor)

Invert 2 phases on the electricity supply

Pressure loss in the suction

Avoid: long pipes, numerous elbows, positioning the pump higher than

the water level, narrow pipes

Make sure the voltage in your supply corresponds to the value

specified on the motor data plate

Make sure the fan grid is free of obstacles (at least 30 cm clearance

between the wall and the fan)

Increase the pump’s operating pressure by slightly closing the delivery

valve (see table below)

Dismount, clean, reassemble

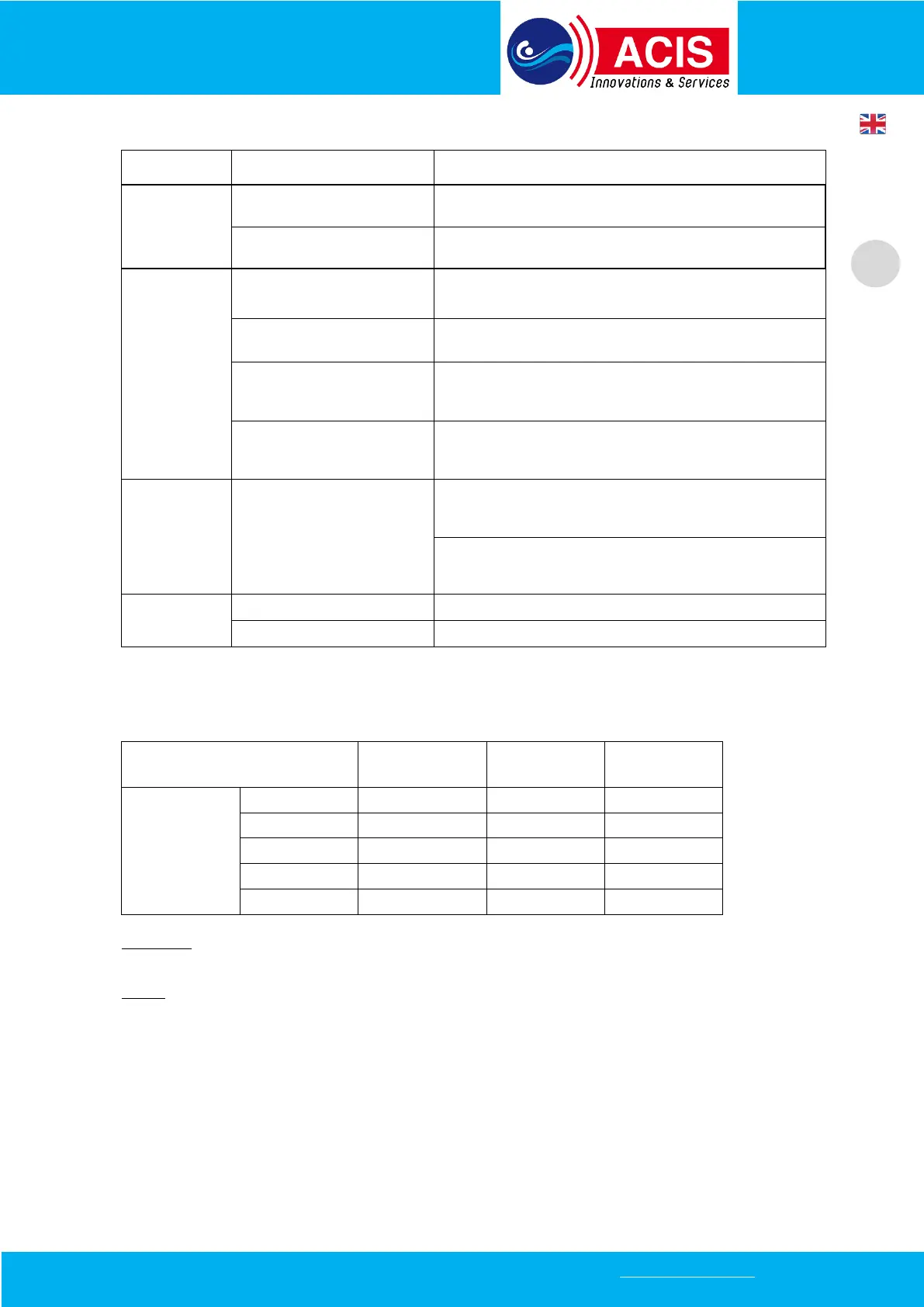

6. MINIMUM OPERATING PRESSURE

Pressure in the

water column

height

Explanation: It is vital that you check the pressures specified above when commissioning the pump. In fact, a pressure

below these minimum values leads to the premature wearing of the pump assembly.

Setting: Close the delivery valve progressively in order to achieve the minimum pressure that corresponds to your model.

Loading...

Loading...