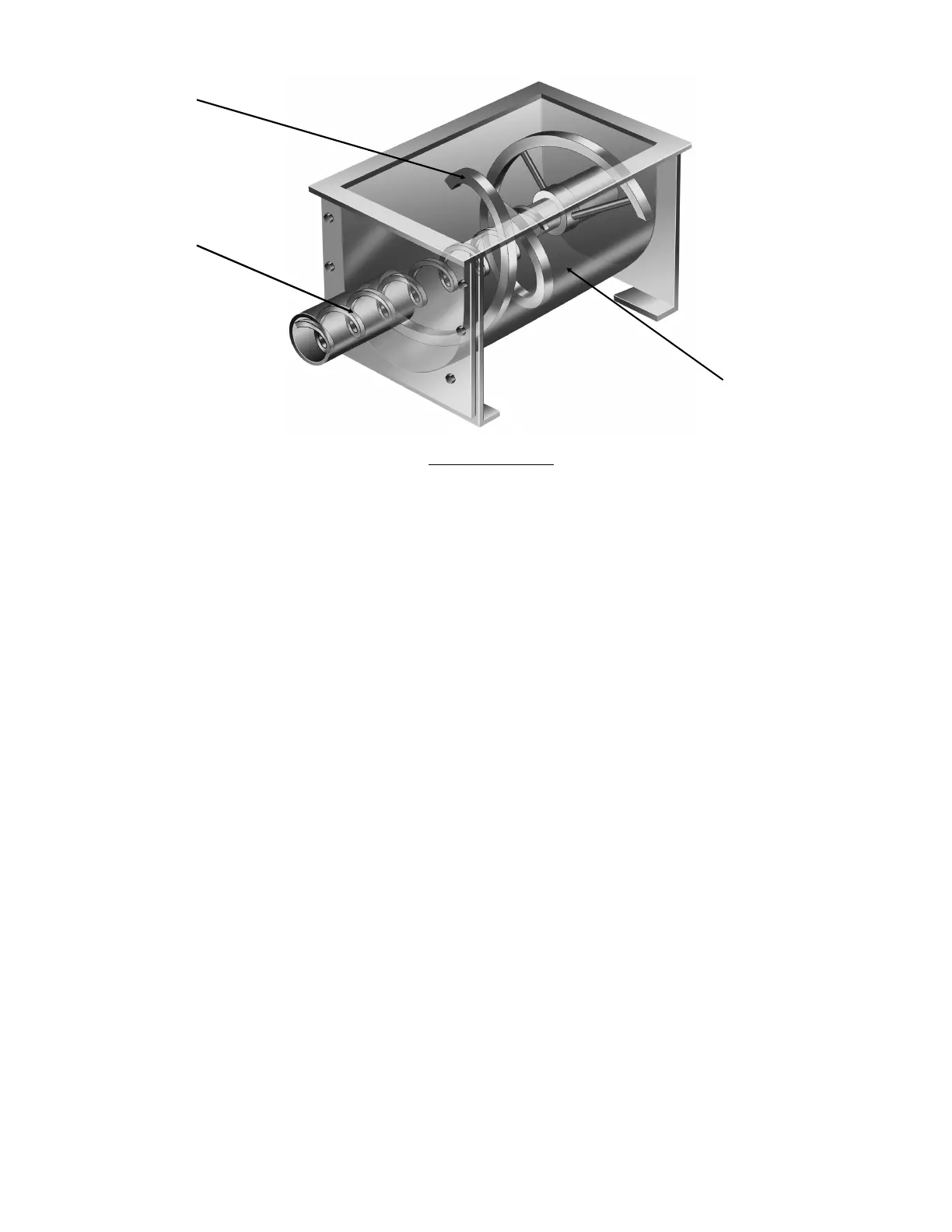

As can be seen from the above Illustration, the large “conditioning” auger (or Intromitter) rotates in the

same direction as the smaller “metering auger,” but at a much slower speed. In operation, as these

augers rotate, a constant and uniform density of material surrounding the metering auger is created and

maintained by the “interaction” between the two concentrically mounted augers rotating at dissimilar

speeds. When product flow characteristics so require, a reverse helical section, added to the Intromitter

(or conditioning auger), produces a bi-directional flow pattern to assist in ensuring optimum density

control. And in order to best handle the countless number of dry solid ingredients efficiently and

effectively, Acrison has designed and manufactures a variety of conditioning augers, the selection of

which is determined by the specific handling characteristics of the material being metered. As standard,

the conditioning auger, discharge cylinder, seal components and double auger drive shafts are 304

stainless steel. The metering auger is 316 stainless steel.

In addition, as the conditioning auger rotates, a gentle inward and outward radial action is generated. The

inward radial action “conditions” the material, establishing uniform product density, while simultaneously,

filling the metering auger from a full 360 degrees.

The outward action creates agitation within the

feeder’s conditioning chamber totally eliminating any possibility of starving the double augers. This

agitation also transmits upwards to product stored above, with the extent of penetration totally dependent

upon the characteristics of the material being fed. In many instances, a “live” hopper of sorts supplies

product to Model 105 Feeders.

The Model 105 Series of Volumetric Feeders consists of three model sizes

…

the Model 105, the

Model 105X and the Model 105Z. The Model 105 utilizes a 6 inch diameter Intromitter (or

conditioning auger), the Model 105X is equipped with an 8 inch diameter conditioning auger, and

the Model 105Z is furnished with a 10 inch diameter conditioning auger. Feeder model selection is

determined by the handling characteristics of the product or products to be fed in conjunction

with the required feed rate.

There is a variety of metering auger sizes available for use with the Model 105 Series of Volumetric

Feeders. Please refer to the Capacity Chart within Section 3.3 of this Manual for the feed output

capacities produced by the various size metering augers available with the particular model feeders.

The Model 105Z Feeder, the largest of the Model 105 Feeder Series, is generally recommended for use

with large storage hoppers, bin dischargers of sorts, or those special applications which require the broad

conditioning chamber (product inlet area), and the subsequent versatility afforded by this particular model

feeder. As standard, the various Model 105 Volumetric Feeders are furnished either with flanged

ILLUSTRATION

Metering

Auger

Conditioning/Feed

Chamber

Conditioning

Auger

5

Loading...

Loading...