PNEUMATIC ACTUATORS

ASSEMBLY & MAINTENANCE PROCEDURES

Ref. Doc. MMMACTREGDRE English Rev.2 – January 2012

9

The use of dry air increases the lifetime of the actuators, as well as the lifetime of their

accessories, solenoids and other pneumatic accessories.

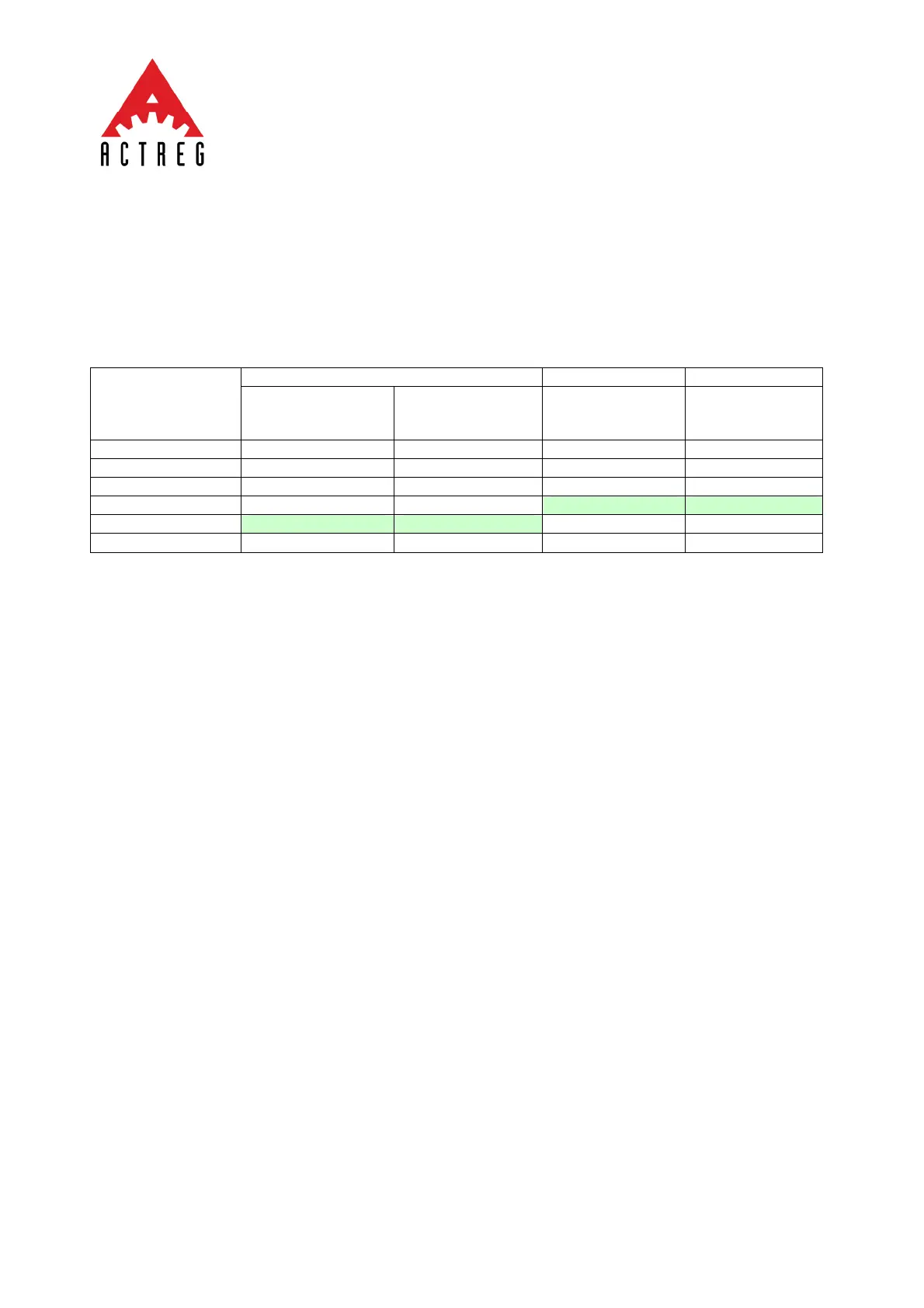

4.2.1 RECOMMENDED MINIMUM AIR QUALITY

For best possible service life and trouble-free operation, ISO 8573-1 quality class 5.4.4

should be used. This means 40 µm filter, dew point +3ºC for indoor operation (a lower dew point

should be selected for outdoor operation, Quality class 3) and oil concentration 5.0mg oil/m³.

Pollution Water Oil

Quality Class

Particle size (µm)

Max. concentration

(mg/m³)

Max. press. dew

point (ºC)

Max.

concentration

(mg/m³)

1 0.1 0.1 -70 0.01

2 1 1 -40 0.1

3 5 5 -20 1.0

4 15 8 +3 5.0

5 40 10 +7 25

6 - - +10 -

4.2.2 LUBRICATION

Actuators are factory lubricated for the lifetime in normal working conditions.

The standard lubricant is suitable for use from -30ºC (-22º F) up to 100ºC (212º F).

For low and high temperature execution, where special grease is required please contact

ACTREG.

For our standard execution we recommend to use Molicote B2.2 Plus grease or silimar.

WARNING !!

Actuators are lubricated during assembly and do not require any further lubrication.

4.3 Make sure that both the actuator and valve are in the same position, open or closed.

4.4 When assembling the actuator on the valve, check their alignment to ensure that the coupling parts

work perfectly aligned.

4.5 The coupling bolts, whether the actuator connects directly to the valve or uses a bracket, must be

tightened proportionally, distributing the stress, before tightening them completely.

4.6 The normal performance of the actuators is to close clockwise and to open anticlockwise.

However, this may be inverted under request.

4.7 ACTREG pneumatic actuators are provided with bi-directional pinion travel stops. Side located stops

allow a full ±5º travel adjustment between 85º and 95º. Adjustment of the counter clockwise and

clockwise rotation limits is accomplished by unscrewing the locking nuts. 1/3 turn of those locking nuts

means 1º of the stroke.

WARNING!!

Do not adjust more than 2.5º each side, designed by the manufacturer. Internal parts could

be damaged.

IMPORTANT !!

It is advisable to operate the actuator twice before fully tightening the coupling bolts in order to

ensure a good centring.

Loading...

Loading...