250V MAX

15A MAX

FUSED

COM

DC

15A

20M

200

K

20K

2K

200

8CYL

6CYL

TACH

X10

5CYL

4CYL

8CYL

OHMS

15

A

31

Position Type Sensors

Position sensors are potentiometers or a type of

variable resistor. They are used by the computer to

determine position and direction of movement of a

mechanical device. Typical position sensor applica-

tions are throttle position sensors, EGR valve posi-

tion sensors, and vane air flow sensors.

• If multimeter overranges on largest

range, then sensor is an open circuit

and is defective.

7. Move RED test lead to sensor SIG-

NAL pin.

• Refer to vehicle service manual for

location of sensor SIGNAL pin.

8. Operate Sensor.

Throttle Position Sensor:

• Slowly move throttle linkage from

closed to wide open position.

• Depending on hook-up, the display

reading will either

increase or de-

crease in resistance.

• The display reading should either

start

at or end at the approximate resis-

tance value measured in Step 6.

• Some throttle position sensors have

an Idle or Wide Open Throttle (WOT)

switch in addition to a potentiometer.

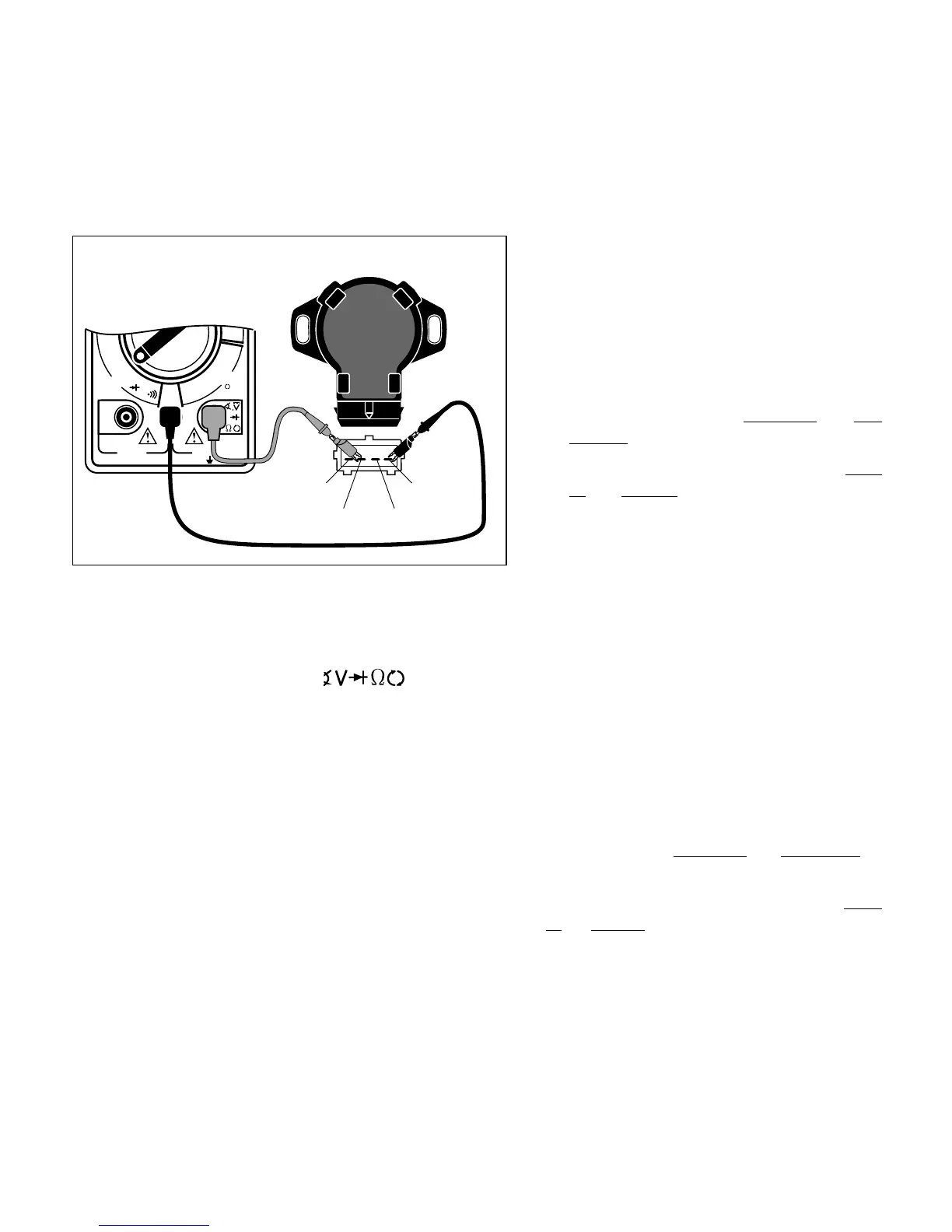

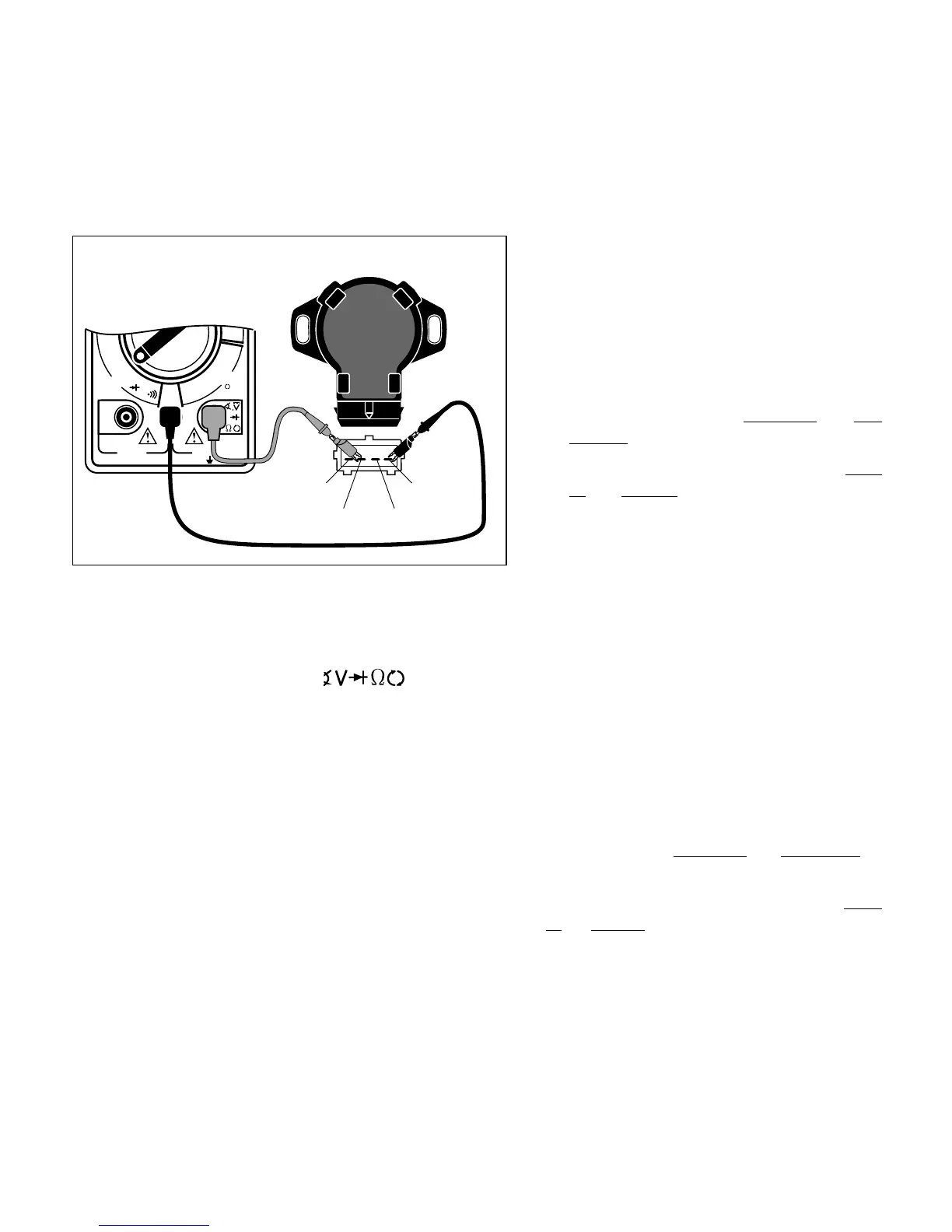

Fig. 32

Test Procedure (see Fig. 32):

1. Insert BLACK test lead into COM test

lead jack.

2. Insert RED test lead into

test

lead jack.

3. Disconnect wiring harness from sen-

sor.

4. Connect Test Leads.

• Connect RED test lead to sensor POWER

pin.

• Connect BLACK test lead to sensor

GROUND pin.

• Refer to vehicle service manual for loca-

tion of sensor POWER and GROUND

pins.

5. Turn multimeter rotary switch to 20K

Ω

range.

6. View and record reading on display.

• Display should read some resistance

value.

• If multimeter is overranging, adjust the

range accordingly. (See Setting the

Range on page 6.)

Typical Toyota Throttle

Position Sensor

Red

Black

POWER GROUND

SIGNAL IDLE SWITCH

• To test these switches, follow the Test-

ing Switches test procedure on page 13.

• When you are told to operate switch,

then move throttle linkage.

Vane Air Flow Sensor:

• Slowly open vane “door” from closed to

open by pushing on it with a pencil or

similar object. This will not harm sensor.

• Depending on hook-up, the display read-

ing will either

increase or decrease in

resistance.

• The display reading should either

start

at or end at the approximate resistance

value measured in Step 6.

• Some vane air flow sensors have an idle

switch and an intake air temperature

sensor in addition to a potentiometer.

• To test idle switch see Testing Switches

on page 13.

• When you are told to operate switch,

then open vane “door”.

• To test intake air temperature sensor see

Temperature Type Sensors on page 30.

Loading...

Loading...