6

Functions

– Installation guide (DRO203, DRO300)

– Probing functions for presets (DRO300)

– Tool compensations (DRO203, DRO300)

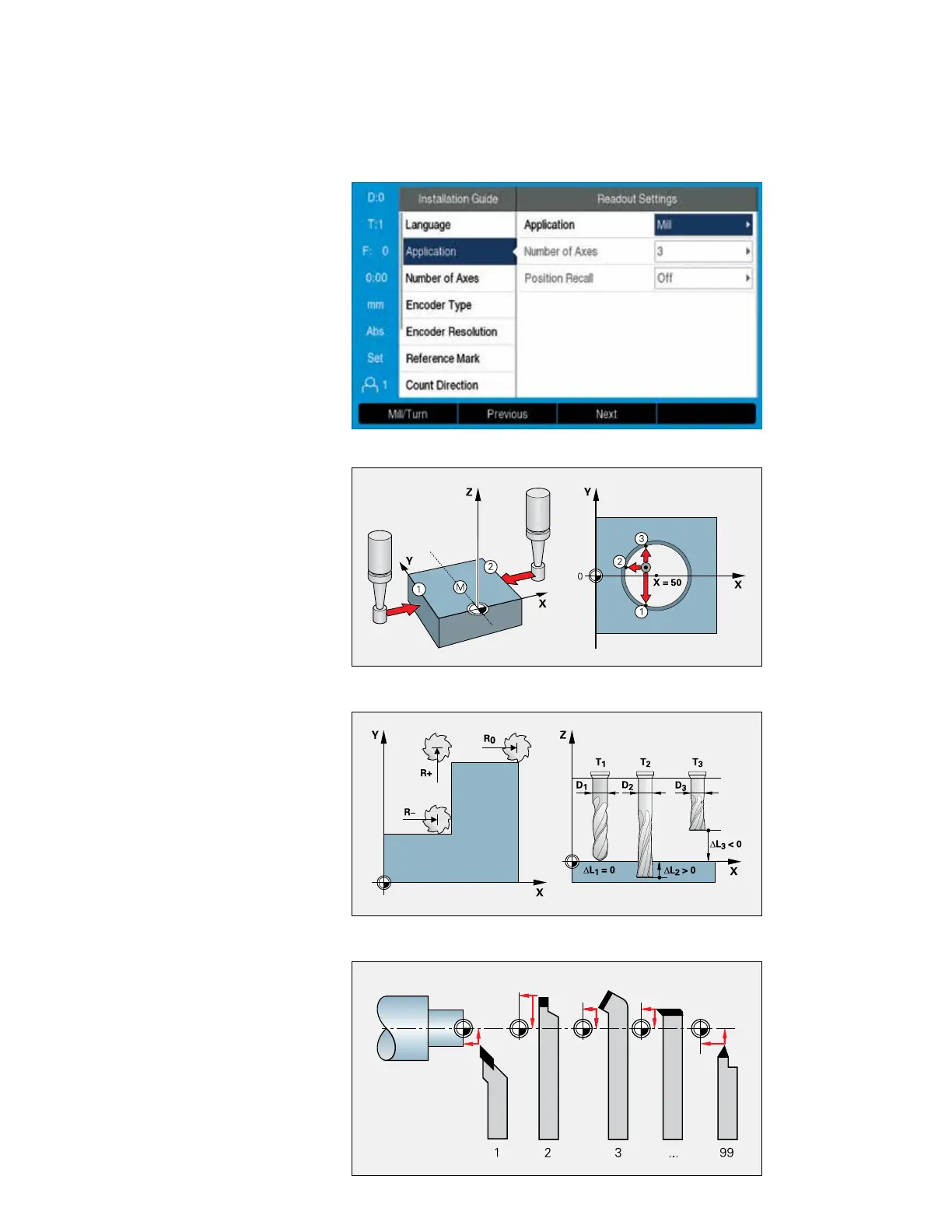

Installation guide

At rst switch-on, an installation guide will

guide you step by step through the congu-

ration of the unit. During this procedure, you

can select the connected encoder directly

from a list and thereby adopt all of the encoder

parameters. It only takes a few moments to

congure the basic functions of the digital

readout.

You can then separately congure further

settings such as scaling factor, error

compensation, etc.

Easy setup with probing functions

A very useful accessory for datum setting is

the HEIDENHAIN KT edge nder: simply

move the edge nder toward a side of the

workpiece until the stylus deects. The

digital readout stores the exact position on

its own and automatically takes into account

the direction of approach and the radius of

the stylus or the tool. For this purpose, the

digital readout provides the following probing

functions:

• Workpiece edge as reference line

• Workpiece centerline as reference line

• Circle center as datum

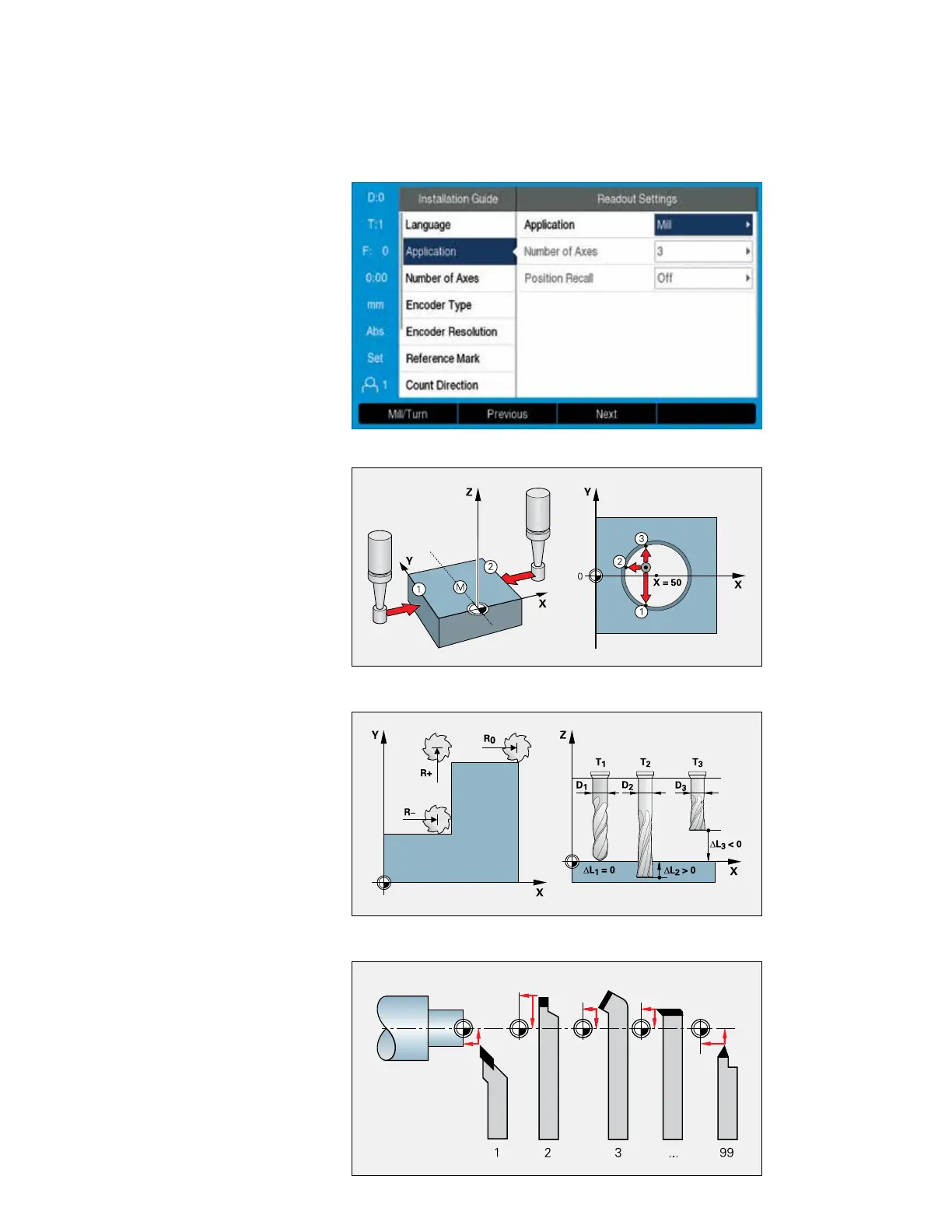

Tool compensation for milling machines

The ACU-RITE digital readouts save tool data

in a tool table (i.e., diameter and length of the

tool used). The data can come from preset

tools or be measured on the machine.

When positioning in distance-to-go mode, the

readouts take the tool radius (R+ or R–) in

the machining plane into account and con-

sider the tool length (L) in the spindle axis.

Determining and storing tool

compensation values on lathes

You can store the data for the tools you insert

in the turret or quick-change holder in the

tool table:

• Enter the tool position directly when

turning the rst diameter, or

• “freeze” the current axis position value,

retract the tool, measure the turned

diameter and then enter that value.

Changing the datum

If you change the workpiece or a datum, then

you can set a new preset. The tool data are

then automatically referenced to the new

datum and do not need to be changed.

Compensation of tool radius and length

Convenient datum setting with an edge nder

Loading...

Loading...