of 20m/s of the thicknessing station and a dust extraction air velocity of 10 m/s instead of 20 m/s,

the noise level will be reduced by about 9 dB(A).

An equivalent continuous sound level of 85 dB(A) is considered to be a danger threshold for a

full-time daily exposure of 8 hours.

The threshold for 4 hours is 88 dB(A), for 2 hours 91 dB(A), for 1/2 hour 97 dB(A) and for 1/4

hour 100 dB(A). Every halving of the exposure time thus allows the danger threshold to be

raised to be 3 dB(A).

Wearing noise protection headphones providing sound level attenuation of 15 dB(A) in all cases

allows you to stay well below the danger threshold with no limit on exposure time.

EXHAUSTING SYSTEM

The machine has to be connected with exhausting appliance of sawdust during any operation.

This exhausting appliance has to embody rapid current of air at least 20 meters per second. The

flexible exhausting hose about the diameter of 10 millimeter will be used for connecting. The

flexible exhausting hoses should be connected to the exhausting tubes, which placing is

following.

Planer – the exhausting tube is placed in area of thicknessing table under the planing table –

diameter 100mm.

Thicknesser – the same exhausting tube as for planing is used, but turned into upper position

over the planing tables – diameter 100mm.

Liquidation of wooden waste has to be done ecologically, so that it would not worsen our

environment.

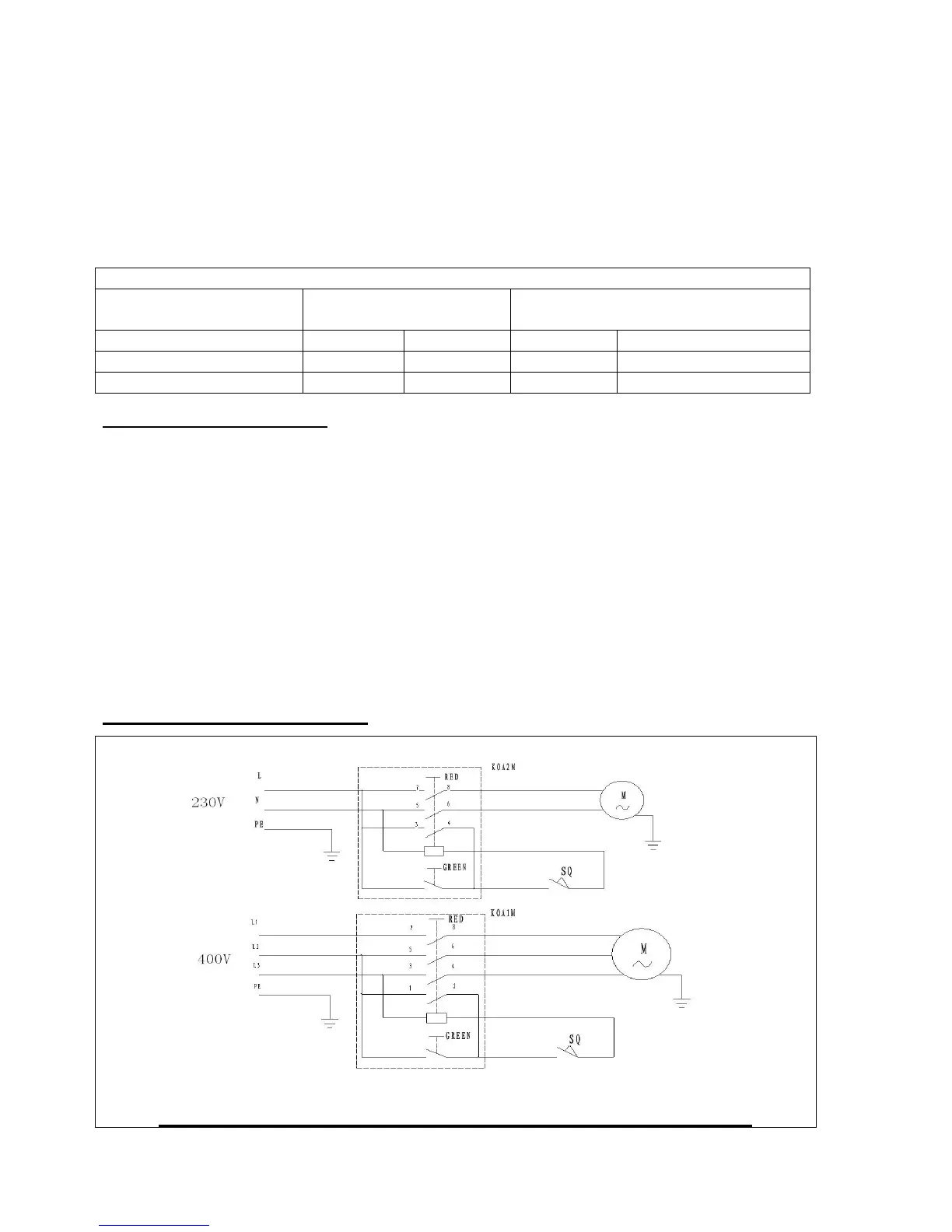

THE ELETRICAL DIAGRAM

Loading...

Loading...