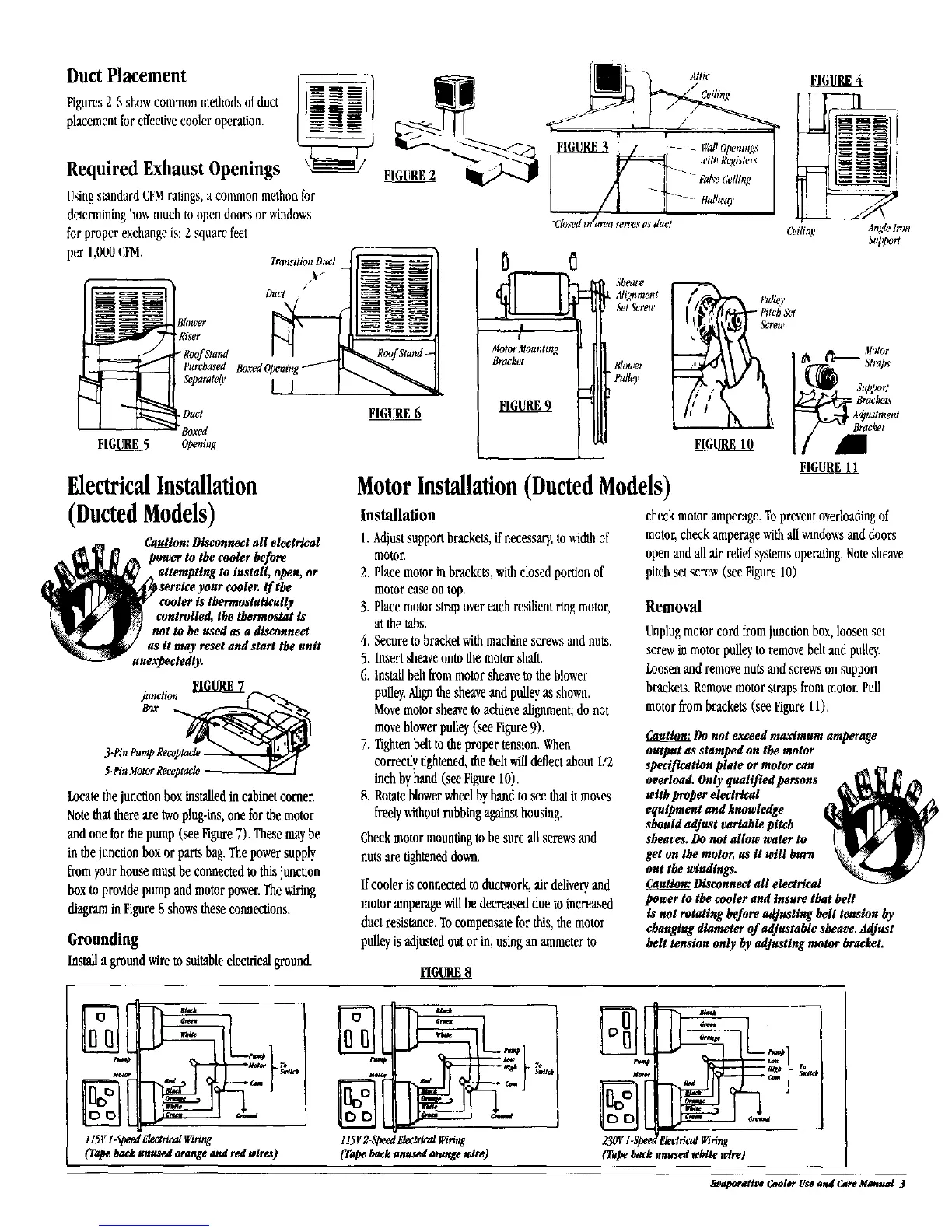

Duct Placement

Figures2-6showcommonmethodsofduct

placementforeffectivecooleroperation.

Required Exhaust Openings

Usingstandard CFMratings, a common methodfor

determining how much to open doom or windows

for proper exchangeis: 2 square feet

per 1,000 CFM.

FIGURE2_

7?ansitionDuct_l_==_

, fin N N

Blower

Rt_er

- RoofSland I I ____[q_oof Stand_

Separately

, Ouct FIGURE6

Boxed

Opening

Electrical Installation

(DuctedModels)

C_ Disconnect all electrical

power to the cooler before

attempting to install, open, or

service your cooler. If the

cooler is thermostatically

trolled, the thermostat is

ot to be used as a disconnect

it may reset and start the unit

ctedly.

lio°

Locatediejunctionboxinstalledincabinetcorner.

Notethattherearetwoplug-ins,onefordiemotor

andonefordiepump(seeFigure7). Thesemaybe

indiejunctionboxorpartsbag.Thepowersupply

fromyourhousemustbeconnectedtothisjunction

boxtoprovidepumpandmotorpower.Thewiring

diagraminFigure8showstheseconnections.

Grounding

Installagroundwiretosuitableelectricalground.

Attic

Ceiling

I "- -.._ with g¢'giste_

Closed in/area sends as duct

FIGA_ . j

Oiling Angle Irotl

Supl_lrt

Alignment Pullel,

Set ,9_'rew Pitch Set

Scre_t

Motor Mounting Motor

Bracket B!ou_r Straps

PullO'

I I _" / _" rt I SuplJort

F_ [ _ Adjustment

\ Bracket

FIG_ U 1! I

FIGURE11

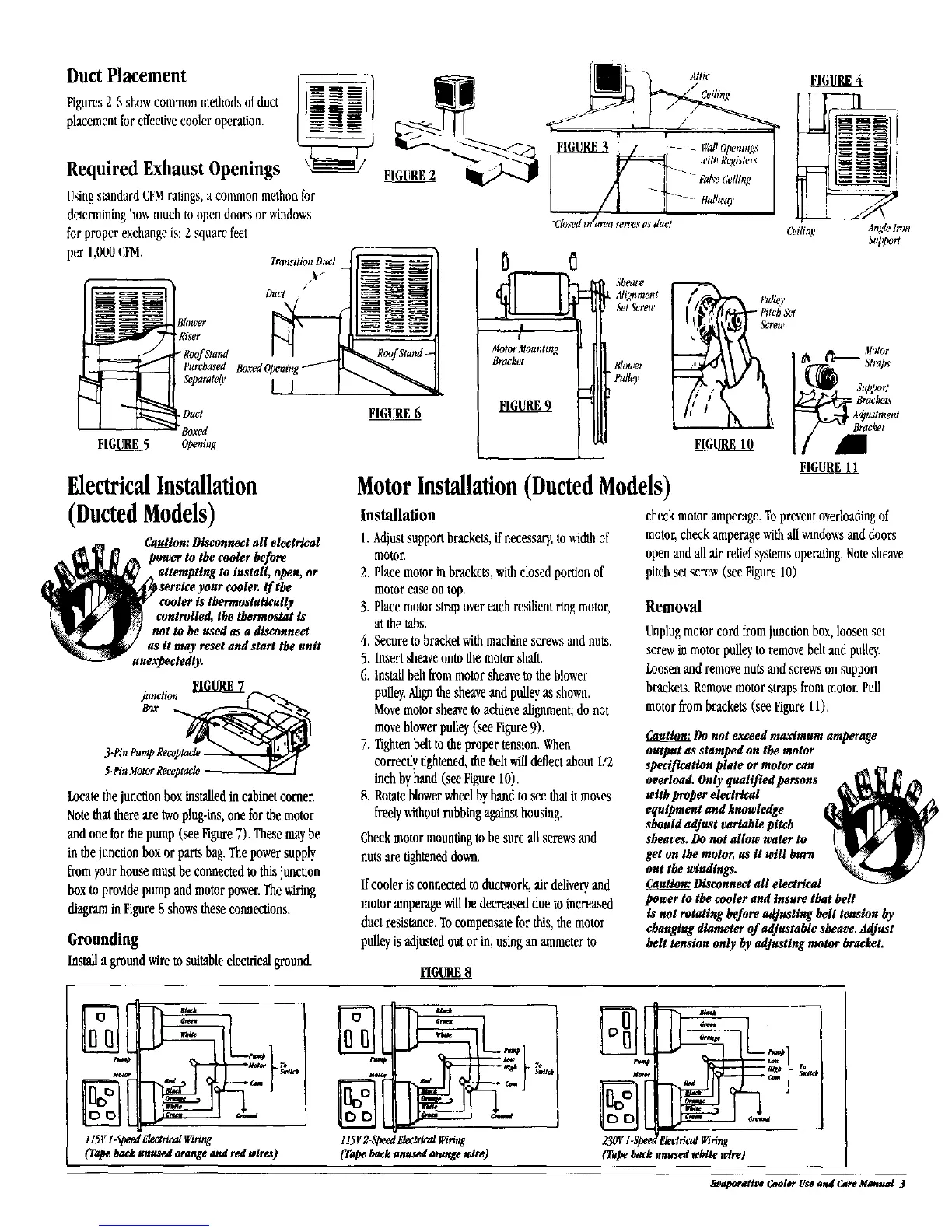

MotorInstallation(DuctedModels)

Installation

1.Adjustsupportbrackets,ffnecessary,towidthof

motor.

2. Placemotorin brackets,withclosedportionof

motorcaseontop.

3. Placemotorstrapovereachresilientringmotor,

at thetabs.

4. Securetobracketwithmachinescrewsandnuts.

5. Insertsheaveontodiemotorshaft.

6. Installbeltfrommotorsheavetodieblower

pulley.Alignthesheaveandpulleyas short;.

Movemotorsheavetoachievealignment;donot

moveblowerpulley(seeFigure9).

7. Tightenbelttothepropertension.When

correctlytightened,diebeltwilldeflectabout1/2

inchbyhand(seeFigure10).

8. Rotateblowerwheelbyhandtoseethatitmoves

freelywithoutrubbingagainsthousing.

Checkmotormountingto besureallscrewsand

nutsaretighteneddown.

checkmotoramperage.Topreventoverloadingof

motor,checkamperagewithallwindowsanddoors

openandallair reliefsystemsoperating.Notesheave

pitchsetscrew(seeFigure10).

Removal

Unplugmotorcordfromjunctionbox,loosenset

screwinmotorpulleytoremovebeltandpulley.

Loosenandremovenutsandscrewson support

brackets.Removemotorstrapsfrommotor.Pull

motorfrombrackets(seeFigure11).

Do not exceed maximum amperage

output as stamped on the motor

specification plate or motor can

overload. Only qualiJ'led persons A _ _

with proper electrical

equtpraent and knowledge

should adjust variable pitch _

sheaves. Do not allow water to _ I _

get on the motor, as it will burn _V_

out the windings. _

Disconnect all electrical

power to the cooler and insure that belt

is not rotating before adjusting belt tension by

changing diameter of adjustable sheave. Adjust

belt tension only by adjusting motor bracket.

ffcoolerisconnectedtoductwork,airdeliveryand

motoramperagewillbedecreasedduetoincreased

ductresistance.Tocompensatefor this,themotor

pulleyisadjustedoutor in,usinganammeterto

II5V l-Speed Electrical Wiring

(Tape back unused orange and red wires)

ll5V2-SpeedWectrical_Sring

(Tapebackunus_l_sg¢ w_re)

btot_r

230VI-sl_e_ ElectricalWiring

(Tapebackunusedwhitewire)

Evaporative Cooler Use and Care Ma_val 3

Loading...

Loading...