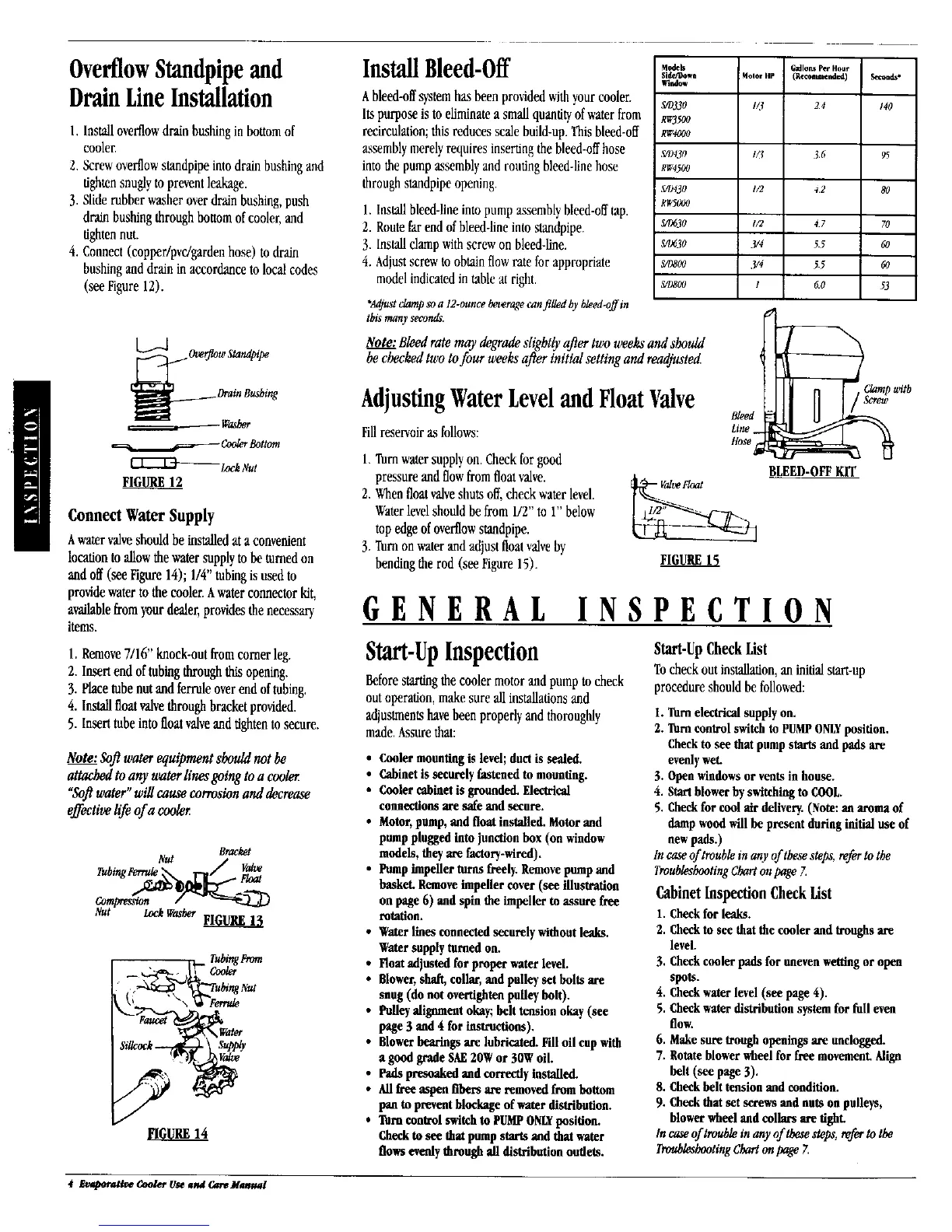

OverflowStandpipeand

DrainLineInstallation

I. Installoverflowdrain bushingin bottom of

cooler,

2. Screwoverflowstandpipe into drain bushingand

tightensnuglyto prevent leakage.

3. Slide rubber washer over drain bushing,push

drain bushing through bouom of cooler, and

tightennut.

4. Connect(copper/pvc/garden hose) to drain

bushingand drain in accordance to local codes

(see Figure 12).

._Over)qow Standpipe

F_

Connect Water Supply

Awatervalveshouldbe installedat aconvenient

locationtoallowthewatersupplytobe turnedon

andoff(see Figure14); 1/4"tubingisusedto

providewatertothecooler.Awaterconnectorkit,

availablefromyourdealer,providesthenecessary

items.

l. Remove7/16"knock-outfromcornerleg.

2. Insertendoftubingthroughthisopening.

3. Plaeetubenutandferruleoverendoftubing.

4. Installfloatvalvethroughbracketprovided.

5. Inserttubeintofloatvalveandtightentosecure.

Note:Softwaterequipmentshouldnot be

attachedtoany waterlinesgoingtoa cooler

"Softwater"willcausecorrosionand decrease

effectivelife ofa cooler

Bracket

ut LockWasher

Faucel Water

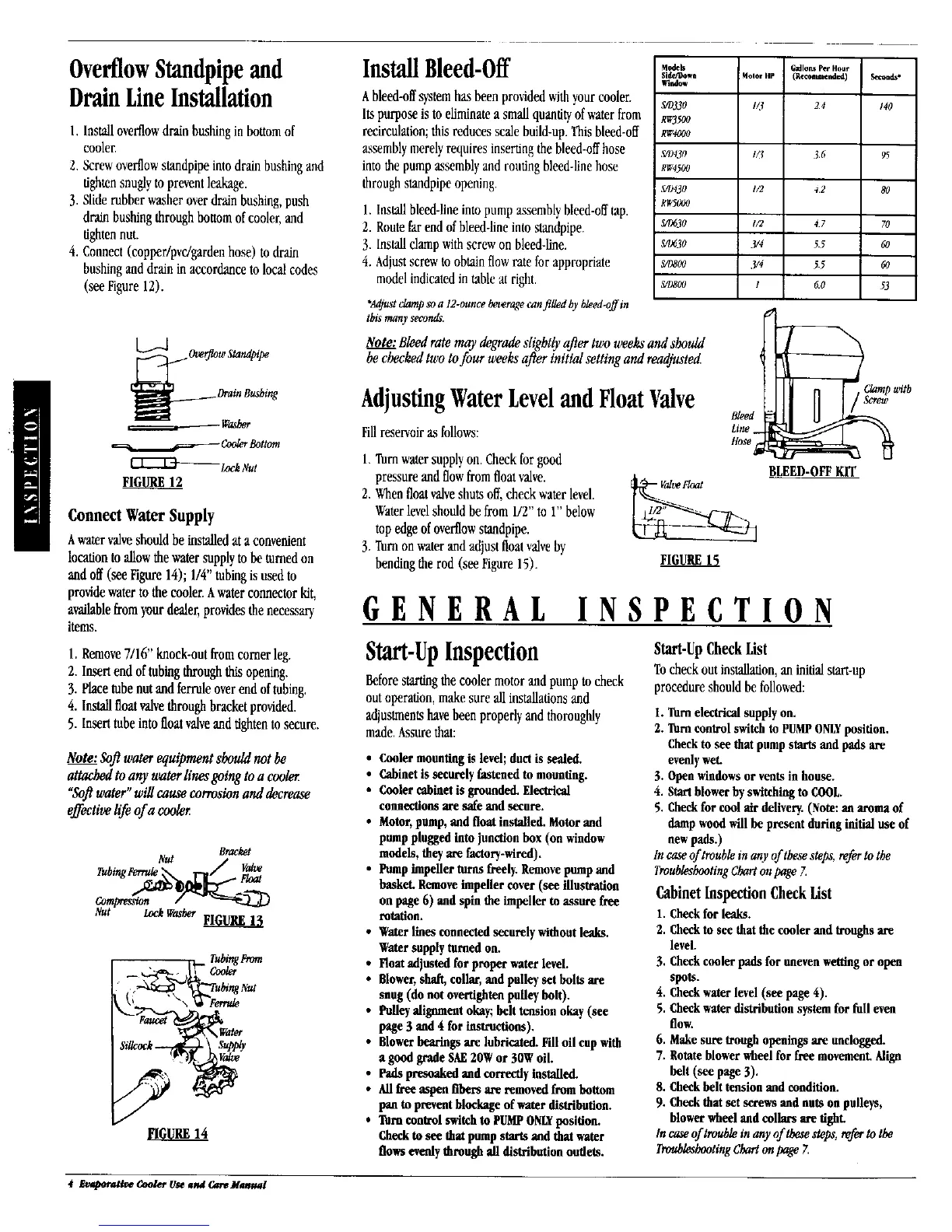

InstallBleed-Off

Ableed-offsystemhas been provided withyourcooler.

Its purpose is to eliminatea small quantityof water from

recirculation; this reduces scale build-up. Thisbleed-off

assemblymerelyrequires insertingthe bleed-offhose

into the pump assemblyand routingbleed-line hose

through standpipe opening.

1.Installbleed-lineintopumpassemblybleed-offtap.

2. Routefarendofbleed-lineintostandpipe.

3. Installclampwithscrewonbleed-hne.

4. Adjustscrewtoobtainflowrateforappropriate

modelindicatedintableat right.

Models Gallons Per Hour

Side/Bow_ Molor HP (Recommended)

wlrdow

S/D330 I/3 24

R_5aO

R_4aO0

,_)430 t/3 36

RW4500

S/D430 I/2 42

RgSO00

S/D630 I/2 47

S/I)630 3/4 _ 5

S/08OO 3/4 _5

S/OSO0 I 60

$t,_nd**

140

95

80

7O

60

60

53

*_t _p soa 12-ounce beveragecanfilled by bleed-offin

thisntanyseconds.

Note:Bleedrate maydegradeslightlyaftertwoweeksand should

becheckedtwotofour weeksafter initialsettingand readjusted

AdjustingWaterLeveland FloatValve

Fillreservoir as follows:

1.Torn watersupplyon. Checkfor good

pressure and flowfrom float valve.

2. Whenfloat valveshuts off, check water level.

Waterlevelshould be from 1/2"to 1" below

top edgeof overflowstandpipe.

3. Torn on waterand adjust floatvalveby

bendingthe rod (see Figure 15).

FIGURE15

Clamp with

BLEED-OFFKIT

GENERAL INSPECTION

Start-UpInspection

Beforestartingthe cooler motorand pump to check

outoperation,makesure allinstallationsand

adjustmentshavebeen properlyand thoroughly

made. Assurethat:

• Coolermountingis level;duetis sealed.

• Cabinetis securely fastened to mounting.

• Coolercabinetis grounded.Electrical

connectionsare safeand secure.

• Motor,pump,endfloat installed.Motorend

pumppluggedintojunctionbox (on window

models, theyare factory-wired).

• Pumpimpellertoms freely.Removepumpend

basket.Removeimpeller cover(see illustration

on page6) andspin the impellerto assurefree

rotation.

• Waterlines connectedsecurelywithoutleaks.

Watersupplyturnedon.

• Floatadjustedfor properwaterlevel.

• Blower,shaft,collar,andpulleyset bolts are

snug(do not ovet_ightenpulleybolt).

• Pulleyalignmentokay;belttension okay(see

page3 and4 for instructions).

• Blowerbearingsare lubricated.Fill oil cupwith

agood grade SAE20Wor 30Woil.

• Padspresoakedend correctlyinstalled.

• Allfree aspen fibers are removedfromboUom

panto preventblockageofwater distribution.

• Trimcontsolswitchto PUMPONLYposition.

Checkto see that pumpstartsend thatwater

flowsevenlythrough all distributionoutlets.

Start-UpCheckList

Tocheckoutinstallation,an initialsturt-up

procedureshouldbefollowed:

I. Turn electricalsupplyon.

2. Turn controlswitchto PUMPONLYposition.

Checkto see that pumpstartsandpadsare

evenlywet.

3. Openwindowsor vents in house.

4. Startblowerbyswitchingto COOL.

5. Checkfor cool airdelivery.(Note:an aromaof

dampwoodwill be present duringinitialuse of

newpads.)

In caseof troublein any of thesesteps,referto the

TmublesheotingChartonpageZ

Cabinet Inspection Check List

1. Checkfor leaks.

2. Checkto see that the cooler andtroughsare

level.

3. Checkcoolerpads forunevenwettingor open

spots.

4. Checkwaterlevel (see page 4).

5. Checkwulerdistribution systemfor lull even

flow.

6. Makesuretroughopeningsare unclogged.

7. Rotateblowerwheel for free movement,Align

belt (see page3).

8. Checkbelt tension andcondition.

9. Checkthat set screwsandnuts on pulleys,

blowerwheelend collarsare tight.

te caseof troublein any of thesesteps,referto the

TroubleshootingChartonpage Z

4 _orativeCoolerUseawACareManual

Loading...

Loading...