V-belt Tension

The AG Dispenser is designed for the optimum performance with minimum requirement

for maintenance.

Conveyor bed bearings are to be kept well greased at all times.

11

Maintenance

The AG Dispenser is designed for the optimum performance with minimum requirement

Conveyor bed bearings are to be kept well greased at all times.

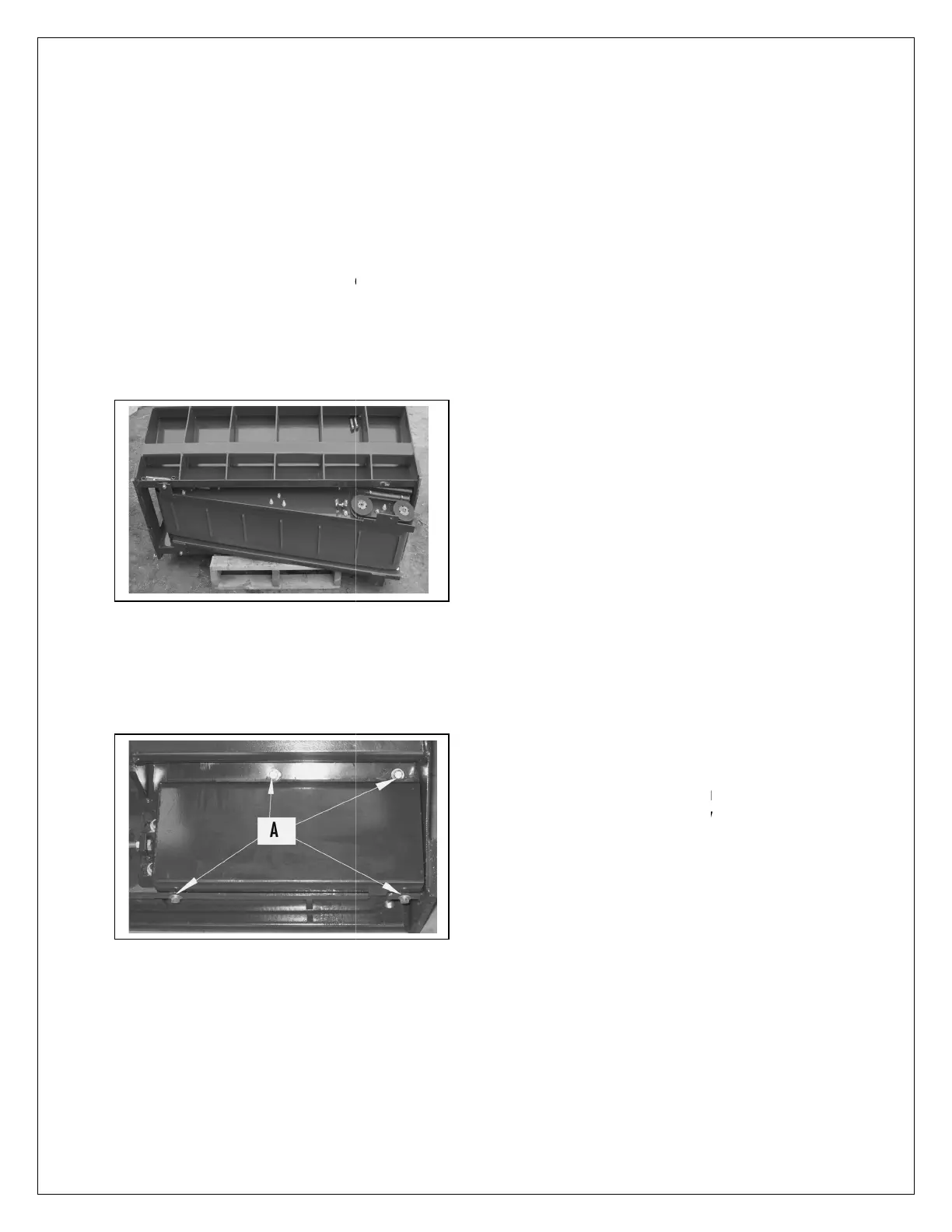

Fig 5.

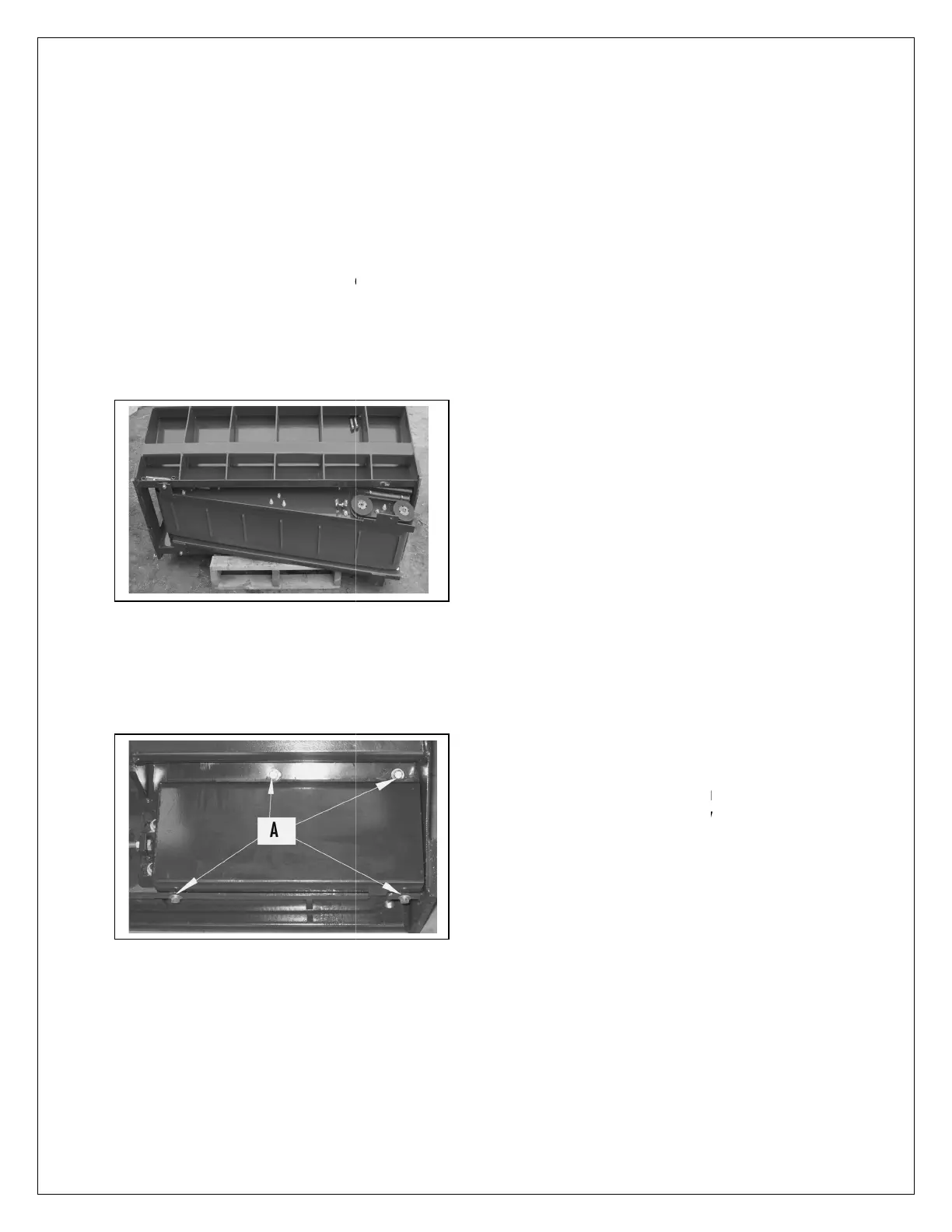

Fig 6.

1.

Dispensers with removable

conveyors, remove two bolts on

the right hand side of the

conveyor. Slacken the two

remaining bolts on the left hand

side. (Fig 5)

2.

Slide the right hand side of the

conveyor out. Ensure not to slide

out to far as hydraulic pipes are

3. AG 150 Dispenser. Place

machine on

stable ground. Remove 4* M8

bolts

Fig 6. This will allow the

4. Once removed bolts, cover with

Grease

Grease will allow

The AG Dispenser is designed for the optimum performance with minimum requirement

Dispensers with removable

conveyors, remove two bolts on

the right hand side of the

conveyor. Slacken the two

remaining bolts on the left hand

Slide the right hand side of the

conveyor out. Ensure not to slide

out to far as hydraulic pipes are

3. AG 150 Dispenser. Place

stable ground. Remove 4* M8

Fig 6. This will allow the

4. Once removed bolts, cover with

Loading...

Loading...