!

Practice all workshop safety procedures at all times!

12

Practice all workshop safety procedures at all times!

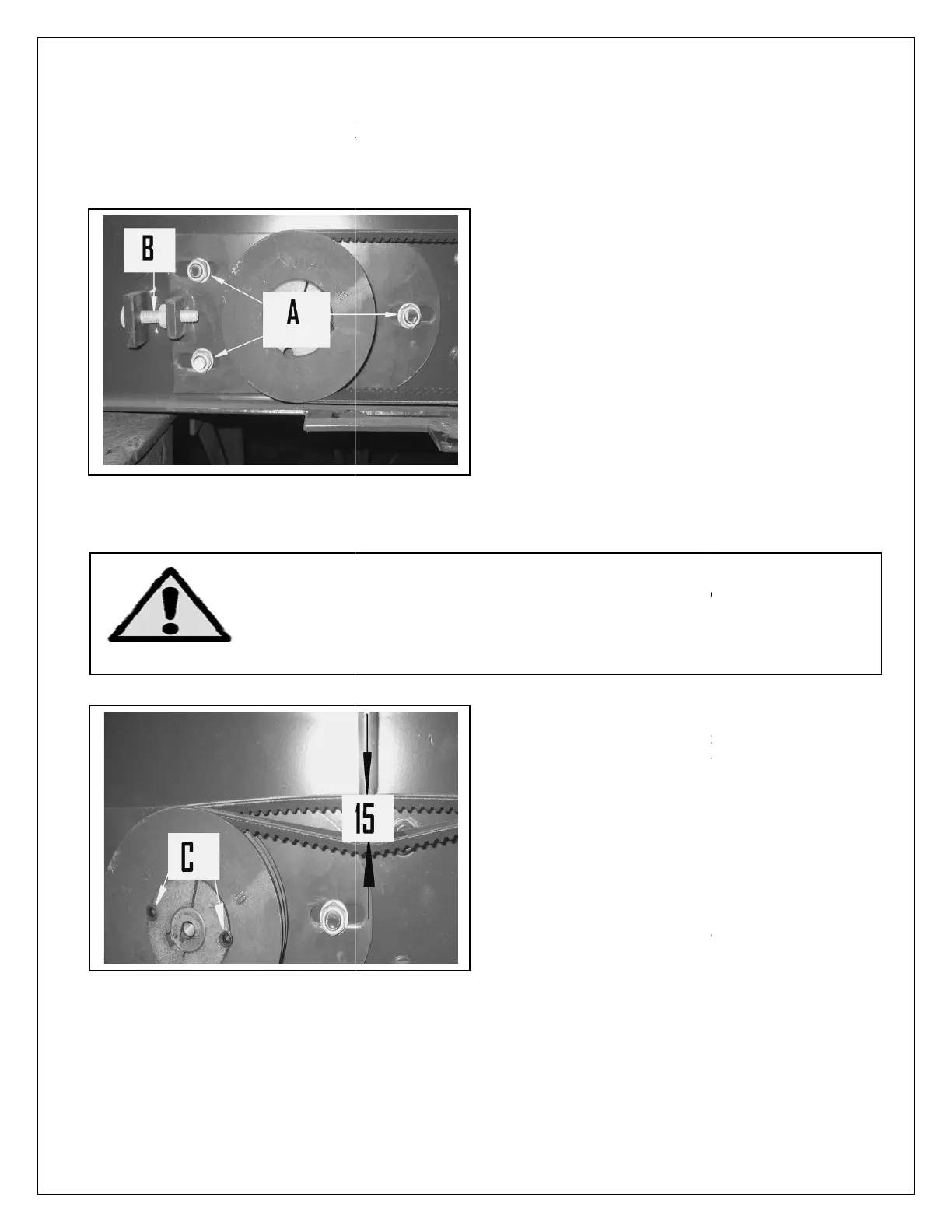

Fig 7.

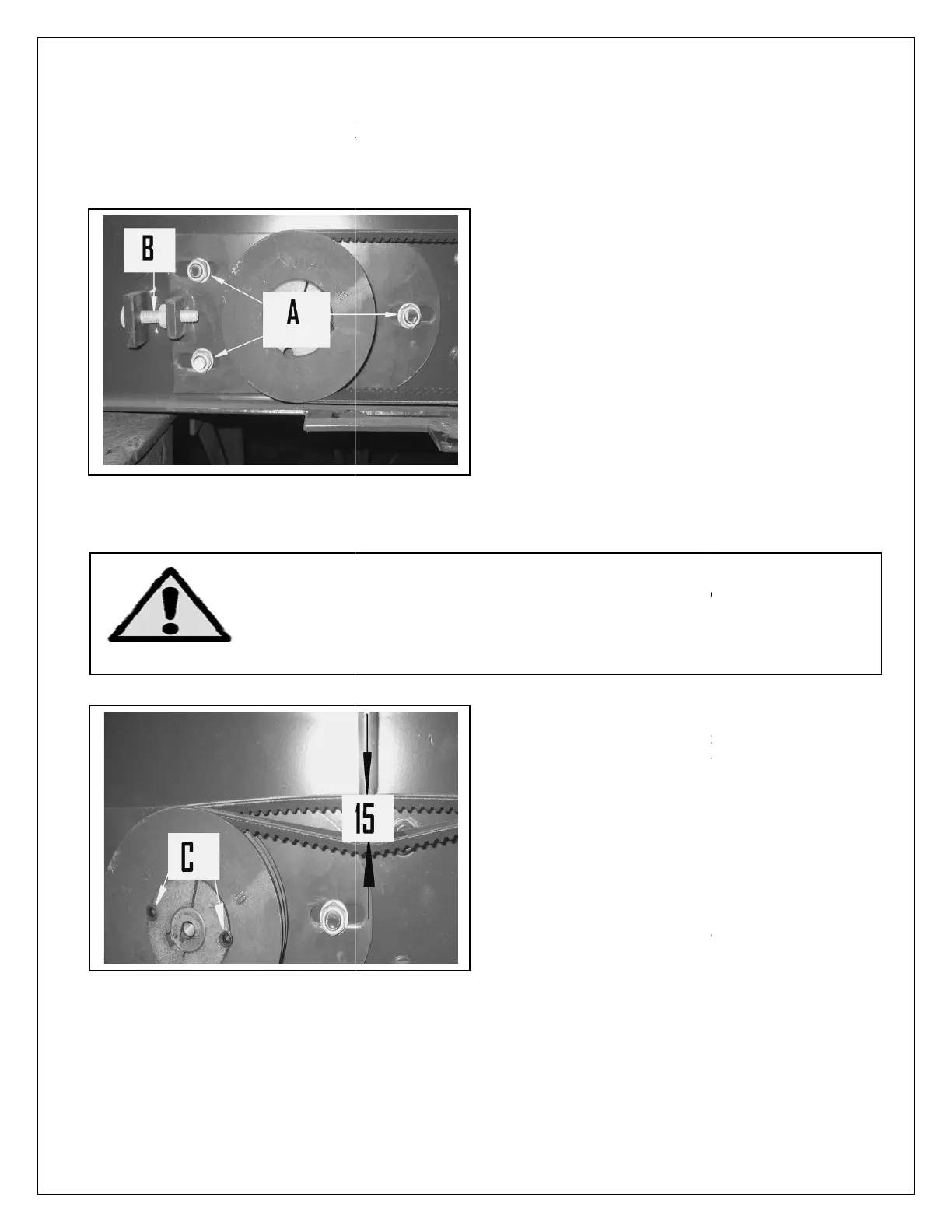

Fig 8.

7. Tension on all V-

belts must be set at 15mm

will cause undue hydraulic motor wear.

Resulting in loss of power on conveyor

bed.

8.

When the correct tension is achieved, lock

the adjuster bolt (B) Fig 7. Tighten M10

nuts (A) Fig 7.

9.

Check Allan bolts (C) Fig 8 are tight.

10. Re-fit conv

eyor AG 175+200, ensure when

re fitting the hydraulic pipes do not catch

or score on the bearing or any metal edges.

11. Re-

fit bolts removed at stage 1 (Fig 5)

12.

stage 3 (Fig 6)

13.

Run and test all machines.

5. To adjust V-

Nuts (item A) Fig 7.

6. Adjust tension using adjuster screw

(Item B).

-

Practice all workshop safety procedures at all times!

belts must be set at 15mm

Excessive belt tension

will cause undue hydraulic motor wear.

Resulting in loss of power on conveyor

When the correct tension is achieved, lock

the adjuster bolt (B) Fig 7. Tighten M10

Check Allan bolts (C) Fig 8 are tight.

eyor AG 175+200, ensure when

re fitting the hydraulic pipes do not catch

or score on the bearing or any metal edges.

fit bolts removed at stage 1 (Fig 5)

-fit guard removed at

Run and test all machines.

6. Adjust tension using adjuster screw

Loading...

Loading...