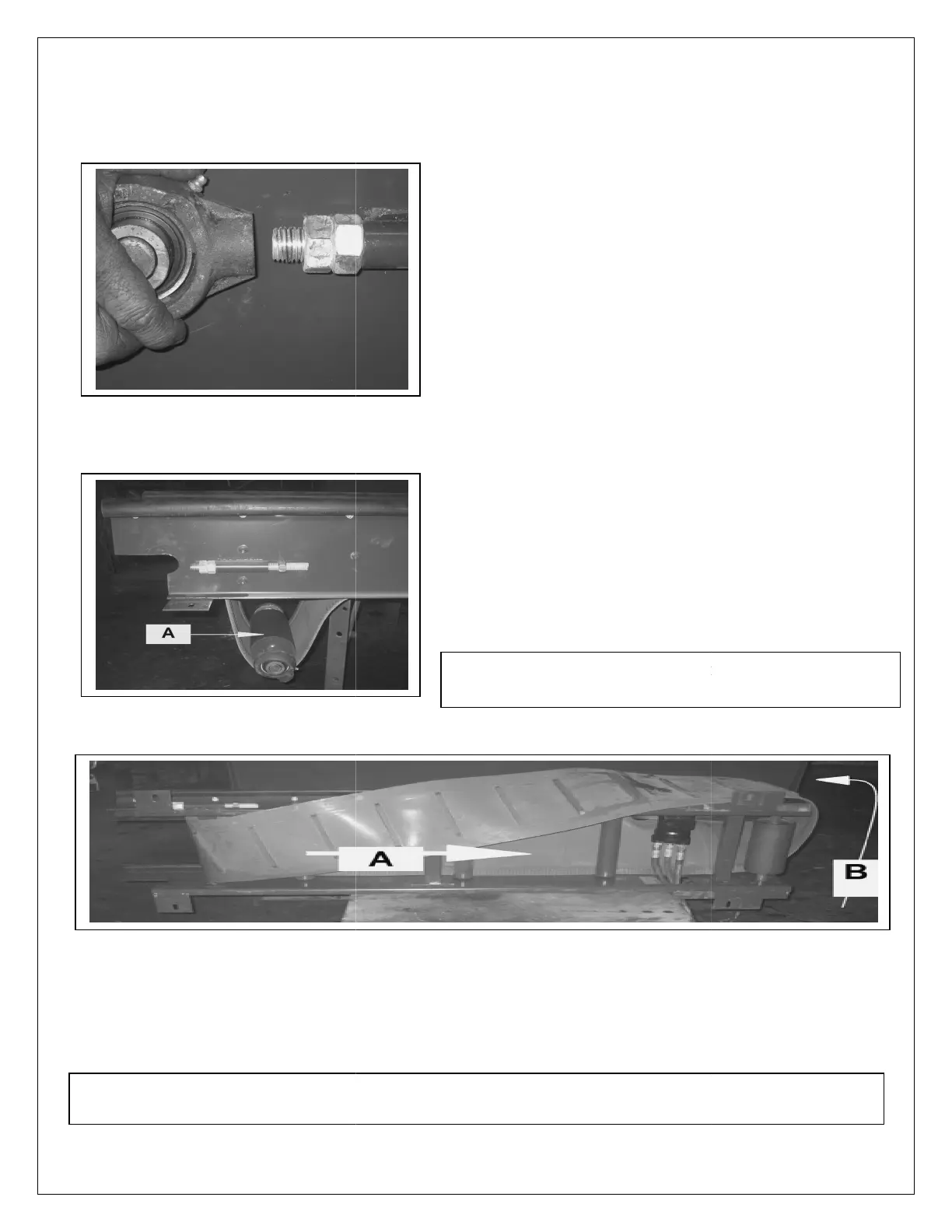

5. Conveyor belt, now to be pulled to other end of the bed (A) Fig 14. Rotate belt in direction (B) Fig 14), allowing belt to

removed.

14

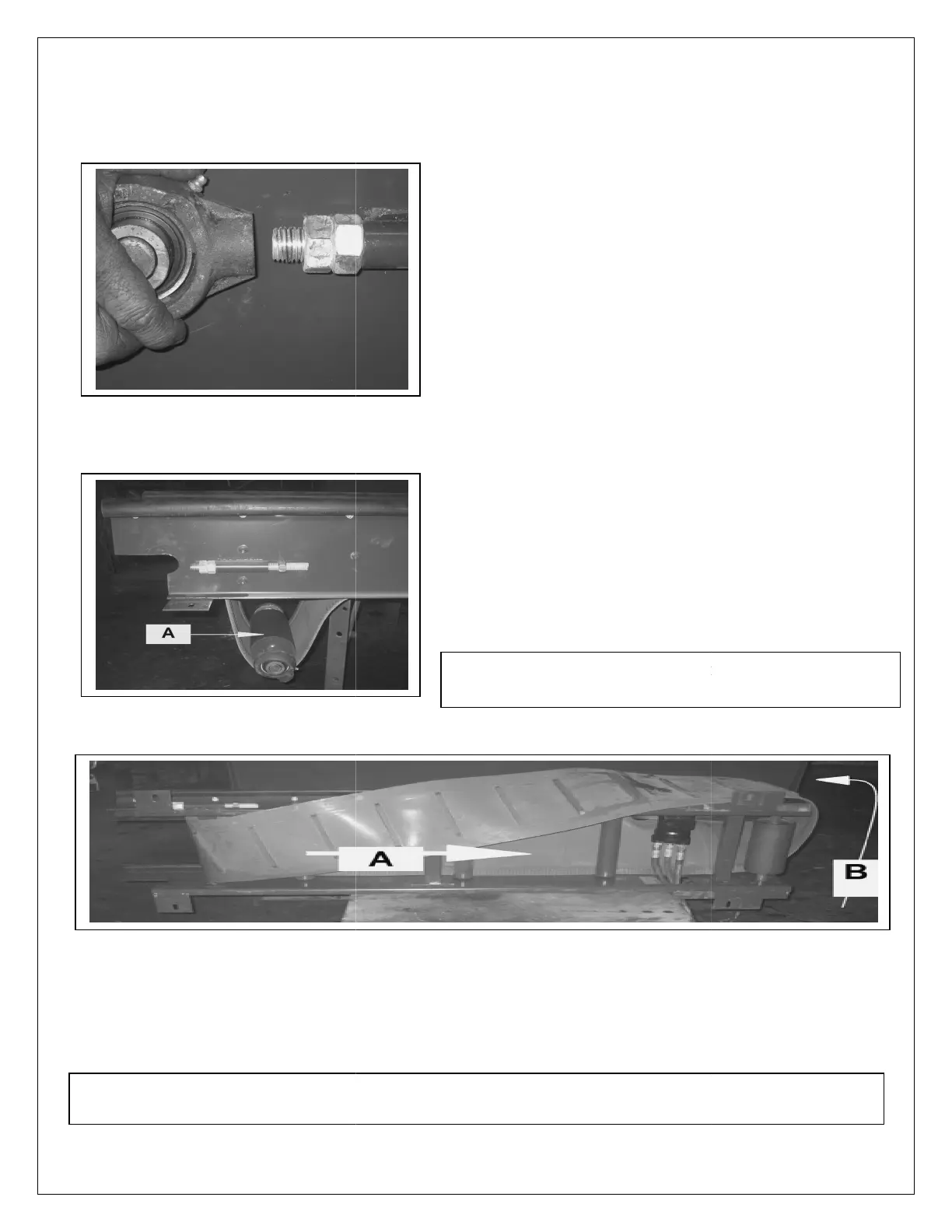

1. Remove the

adjuster threaded bar from the Hanger

bearing. This is easily achieved by locking the two

nuts together, then using the locked nuts to remove

thread from bearing.

2.

Complete this task on both sides of the conveyor.

3.

Fig 13 shows the result. Head roller (A

bearings. It is not required to remove the bearing

from the head roller shaft.

4.

Now remove the assembly (A) from the conveyor.

Removing

assembly (A), may require some gentle

5. Conveyor belt, now to be pulled to other end of the bed (A) Fig 14. Rotate belt in direction (B) Fig 14), allowing belt to

TO BE REPLACED EVERY TWO YEARS

Fig 14

adjuster threaded bar from the Hanger

bearing. This is easily achieved by locking the two

nuts together, then using the locked nuts to remove

Complete this task on both sides of the conveyor.

Fig 13 shows the result. Head roller (A

) c/w two

bearings. It is not required to remove the bearing

Now remove the assembly (A) from the conveyor.

assembly (A), may require some gentle

5. Conveyor belt, now to be pulled to other end of the bed (A) Fig 14. Rotate belt in direction (B) Fig 14), allowing belt to

be

TO BE REPLACED EVERY TWO YEARS

!

Loading...

Loading...