CHECKS -

Fig 15

Fig 16

Fig 17

15

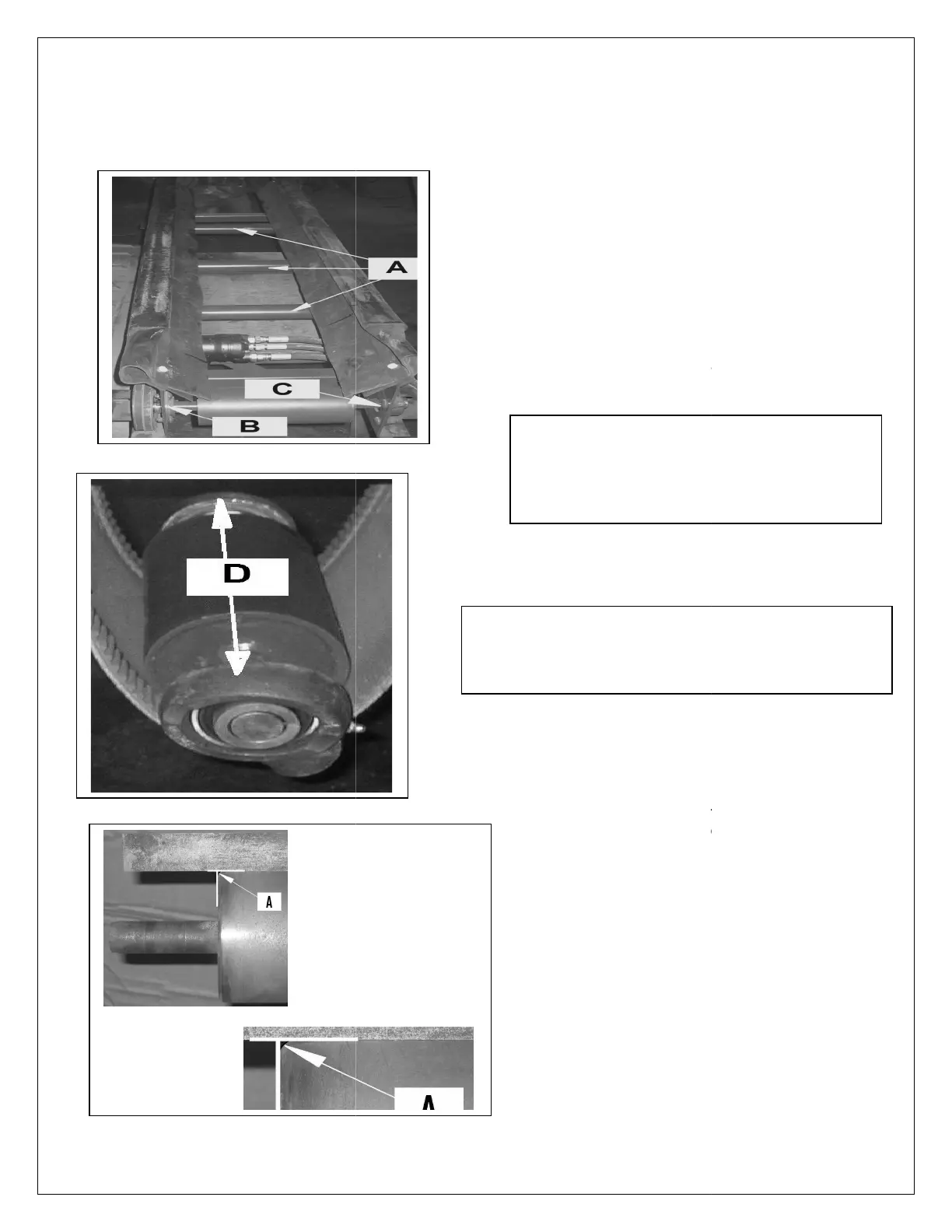

6. Check idler rollers (A) Fig 15 for

wear. These are non

serviceable

items, and must be replaced if

any wear has incurred.

7. Item (B) Fig 15. Check for wear.

8. Item (C) Fig 15. Check for wear.

9. Item (D) Fig 15. Chec

10. Grease all bearings (C and

D).Ensure the nipples are clean.

Do not over grease otherwise

Bearing seals may be damaged.

11. Check all bolt heads on the

conveyor bed for wear. If main

discharge belt has run of track,

bolt head wear will occur.

12. Check side skirts wear.

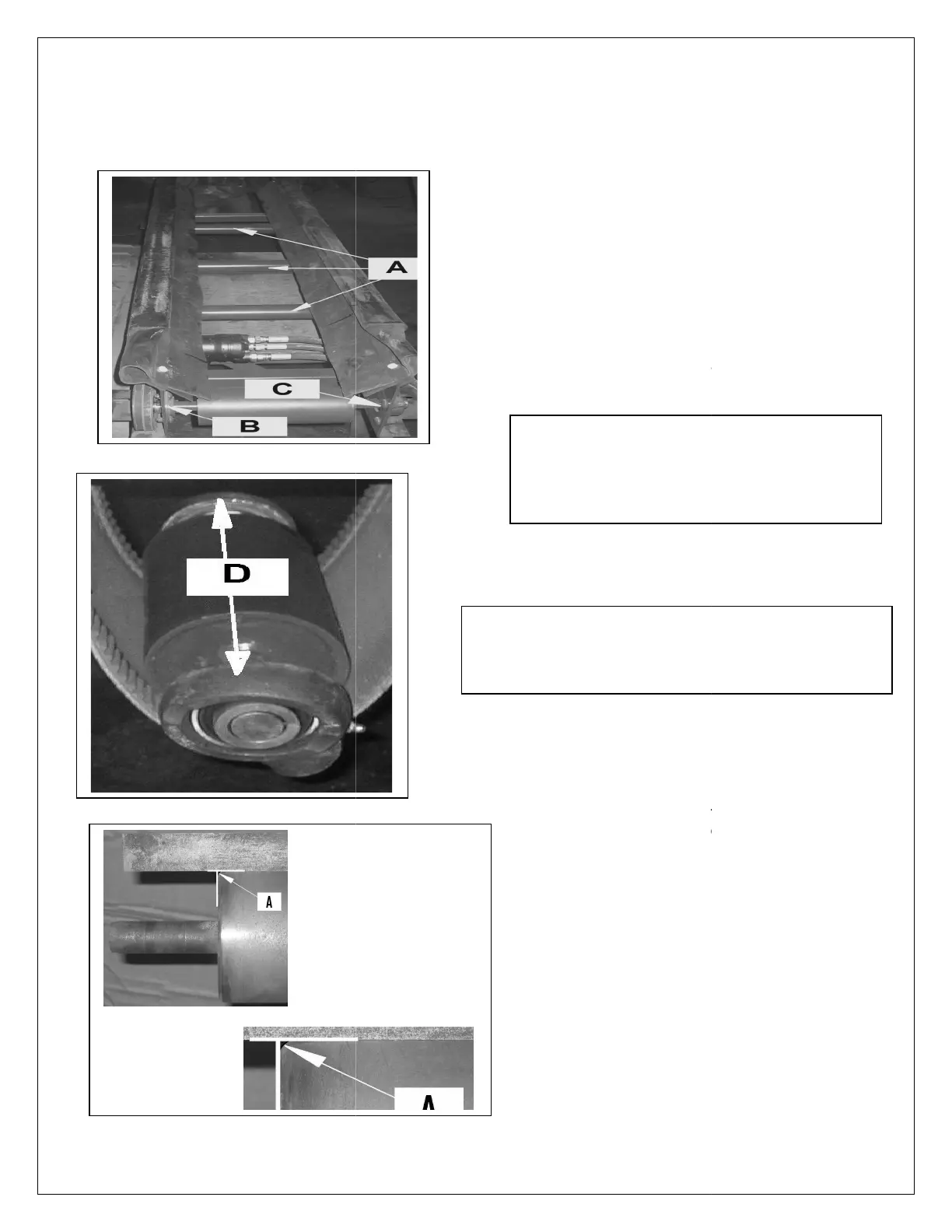

13. Check head and tail rollers for

wear. Fig 17 (A) shows typical

worn roller. Replace with new

part.

14 A worn

roller will result in miss

alignment of the discharge

belt.

allow unqualified or inexperienced

personal to work on, or in this machine.

Always

inform other people what you are doing.

allow unqualified or inexperienced

personnel to work on, or in this machine.

Always

inform other people what you are

doing and remove keys from prime mover

6. Check idler rollers (A) Fig 15 for

items, and must be replaced if

7. Item (B) Fig 15. Check for wear.

8. Item (C) Fig 15. Check for wear.

10. Grease all bearings (C and

D).Ensure the nipples are clean.

Do not over grease otherwise

Bearing seals may be damaged.

11. Check all bolt heads on the

conveyor bed for wear. If main

discharge belt has run of track,

bolt head wear will occur.

12. Check side skirts wear.

13. Check head and tail rollers for

wear. Fig 17 (A) shows typical

worn roller. Replace with new

roller will result in miss

alignment of the discharge

allow unqualified or inexperienced

personal to work on, or in this machine.

inform other people what you are doing.

allow unqualified or inexperienced

personnel to work on, or in this machine.

inform other people what you are

doing and remove keys from prime mover

Loading...

Loading...