16

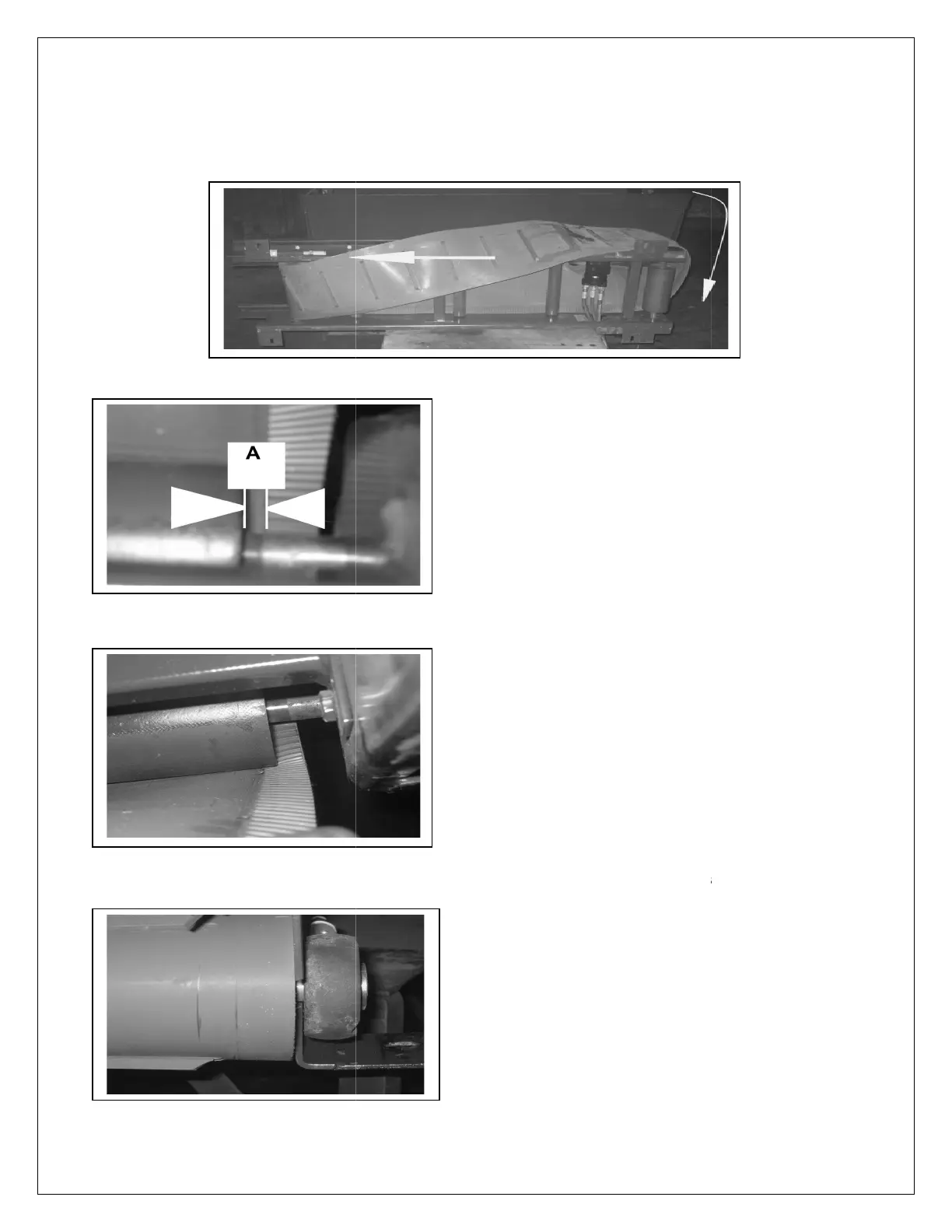

Fig 19

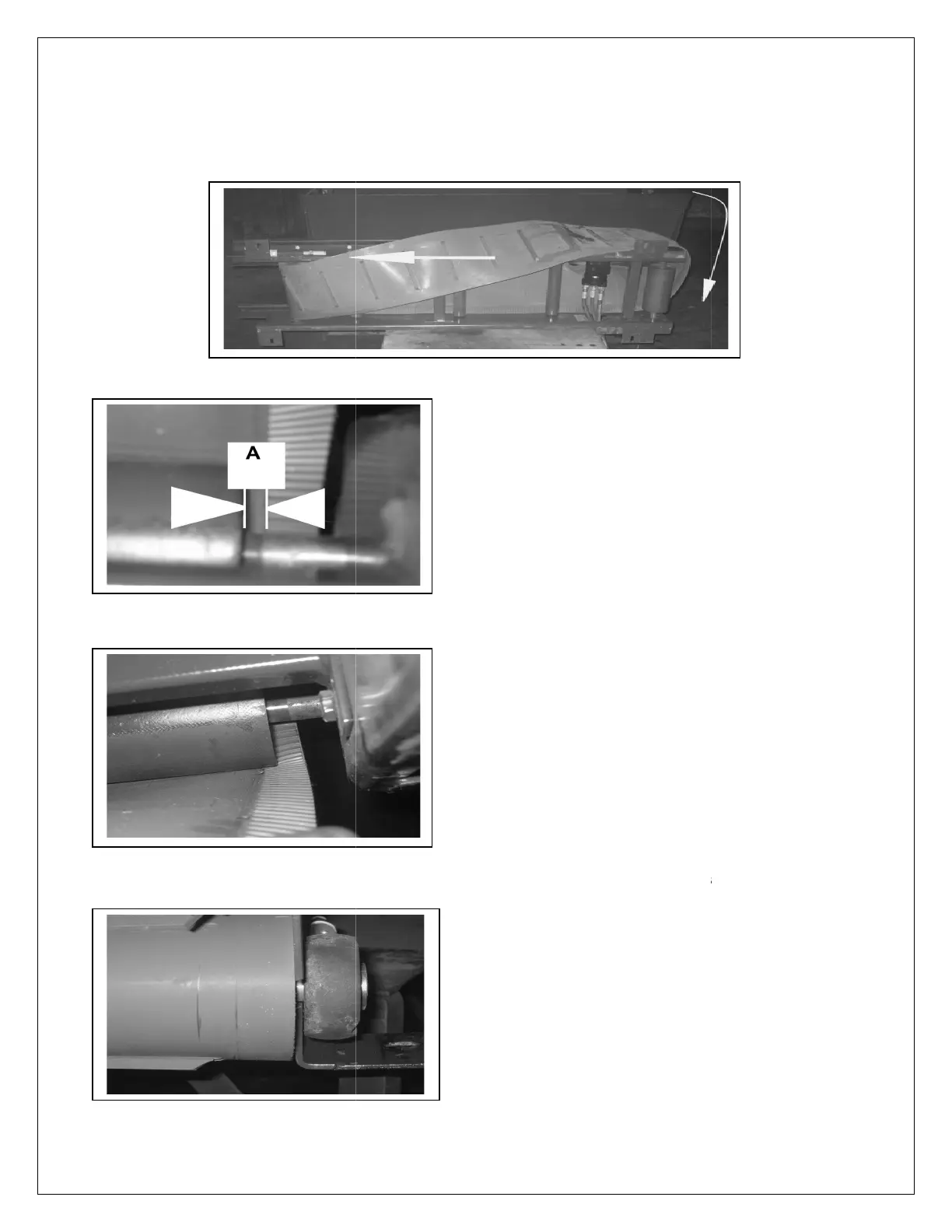

Fig 20

1.

As shown in Fig 18, slide the belt onto

the conveyor frame. Advisable to wear

gloves.

2.

Refit the rail roller c/w bearings Fig 12,

ensuring the nuts are securely

fastened.

3.

Belt alignment is important. Fig 19 (A)

shows a clearance from the end of the

roller and the under tracking of the belt.

This distance needs to be equal on both

sides of the roller and both ends of the

conveyor.

4.

Fig 20 and 21 show poorly adjusted

belt.

The reason for this occurring is due to

the incorrect adjustment shown in Fig

12 and 21, and causes wear shown in

Fig 17

As shown in Fig 18, slide the belt onto

the conveyor frame. Advisable to wear

Refit the rail roller c/w bearings Fig 12,

ensuring the nuts are securely

Belt alignment is important. Fig 19 (A)

shows a clearance from the end of the

roller and the under tracking of the belt.

This distance needs to be equal on both

sides of the roller and both ends of the

Fig 20 and 21 show poorly adjusted

The reason for this occurring is due to

the incorrect adjustment shown in Fig

12 and 21, and causes wear shown in

Loading...

Loading...