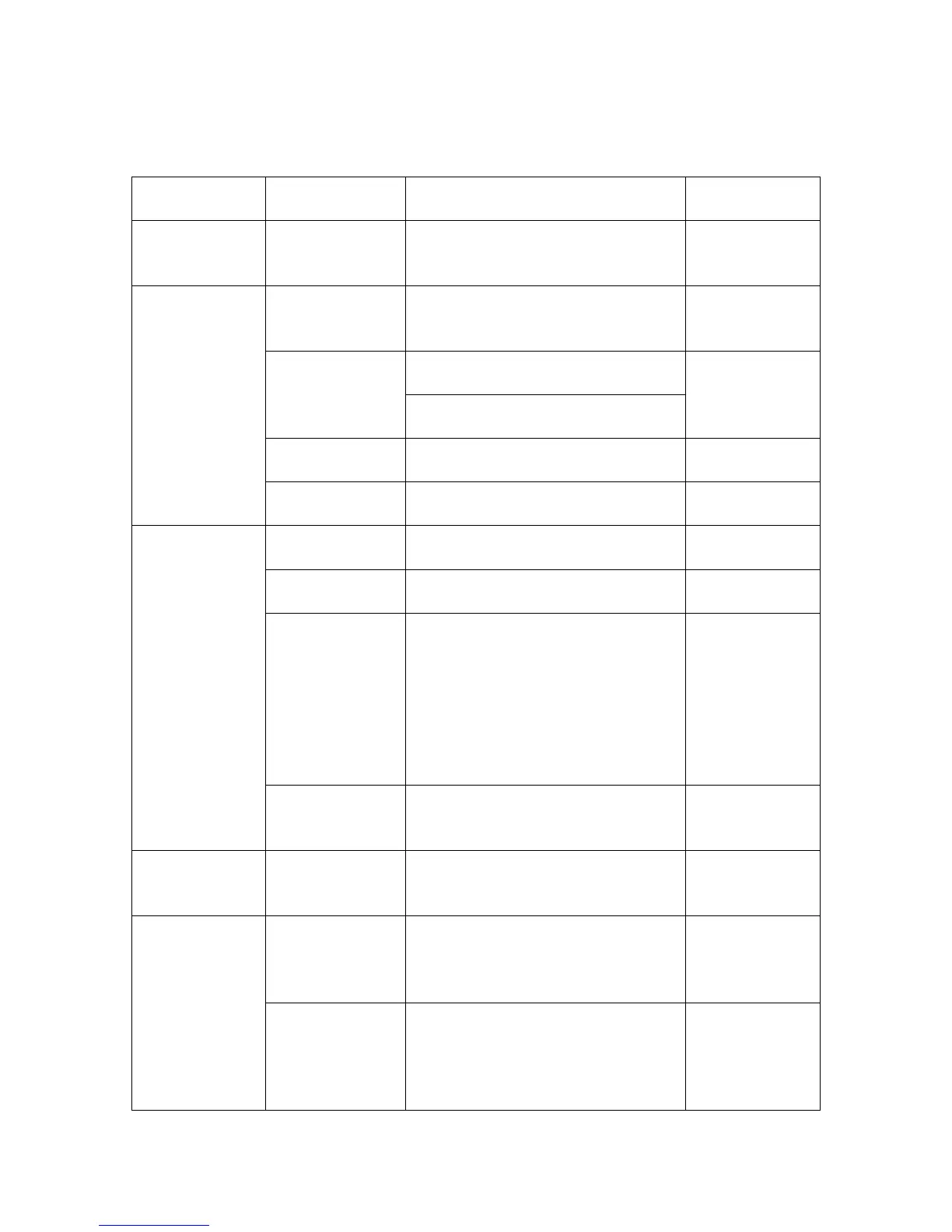

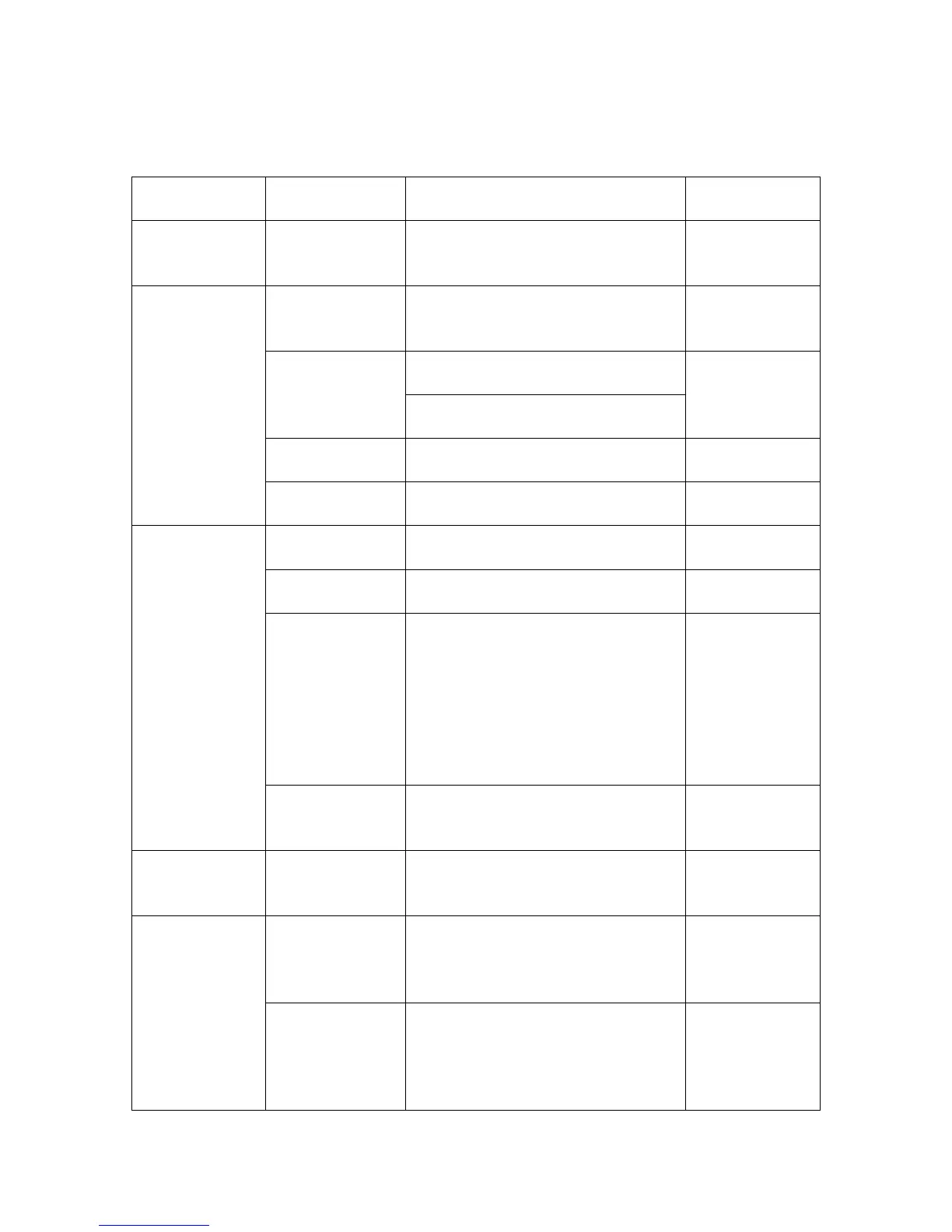

Party

Motor does

not start, no

noise.

Two or more

power legs

interrupted

Check fuses, terminals, etc.. for

source of interruption and

correct.

Electrician

Motor does

not start,

humming

noise.

One power

supply lead

interrupted

Check fuses, terminals, etc.. for

source of interruption and

correct.

Electrician

Impeller is

jammed.

Open blower cover, remove

debris, clean.

Service

Technician

Check impeller clearance and

reset if necessary.

Defective

Impeller

Replace impeller. Service

Technician

Defective

Bearing

Replace defective bearing. Service

Technician

Trip of motor

starter at

start-up

Incorrect

starter setting

Ensure starter setting is correct

(check current on nameplate)

Electrician

Winding short-

circuit

Megger motor Electrician

Motor

overloaded

due to

operation of

pump at

excessive

differential

pressures.

Inspect filters, mufflers and

connection pipes and clean as

required.

Check relief valve operation.

Reset or replace as necessary.

Operator

Impeller

Jammed

See above fault Motor does not

start, humming noise, cause

jammed impeller.

Operator

Excessive

Power

Consumption

Lime or other

deposits

Decalcify or clean unit as

required (see Maintenance

Chart)

Operator

No Vacuum

or Pressure.

Severe leak in

system

Close off pump and run

deadheaded to confirm pump is

operating properly. If so, find

and fix leak in the system.

Operator

Wrong

direction of

rotation

Check air flow direction and

change direction of rotation if

necessary.

Operator

Electrician

Loading...

Loading...