The oil pump. The face of the oil pump body, where it joins the crank-

case, must be perfectly flat also free from bruises and blemish; otherwise

the oil “pick up” from the pump will be curtailed, as the pump will suck

air at this point. Use a little Wellseal as jointing compound on the pump

body when fitting.

There are more than one type of oil pump worm nut and pump pinions.

If at any time hew parts are fitted, check the new ones against the old

ones before they are installed. The pump pinions are of the three start

type. If the pump is dismantled, on assembly make sure the end plates do

not protrude over the pump body; they should be just below the pump

body.

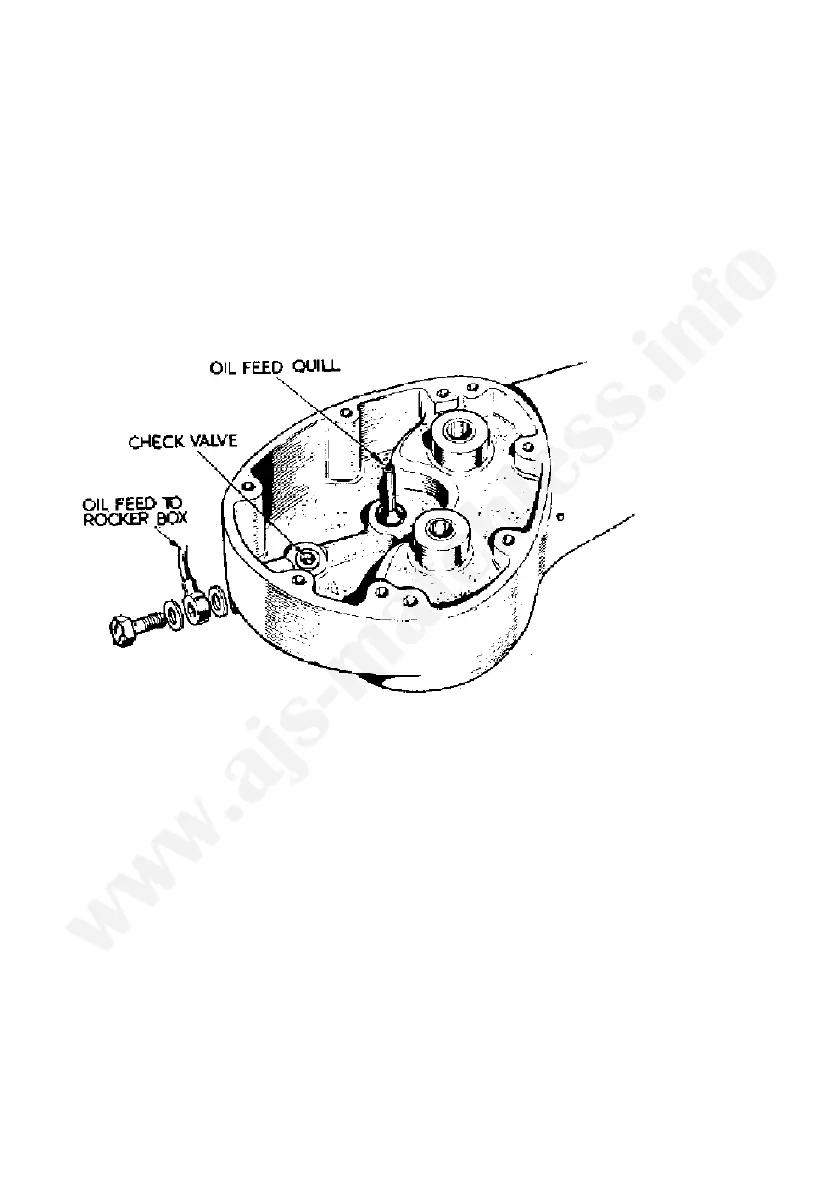

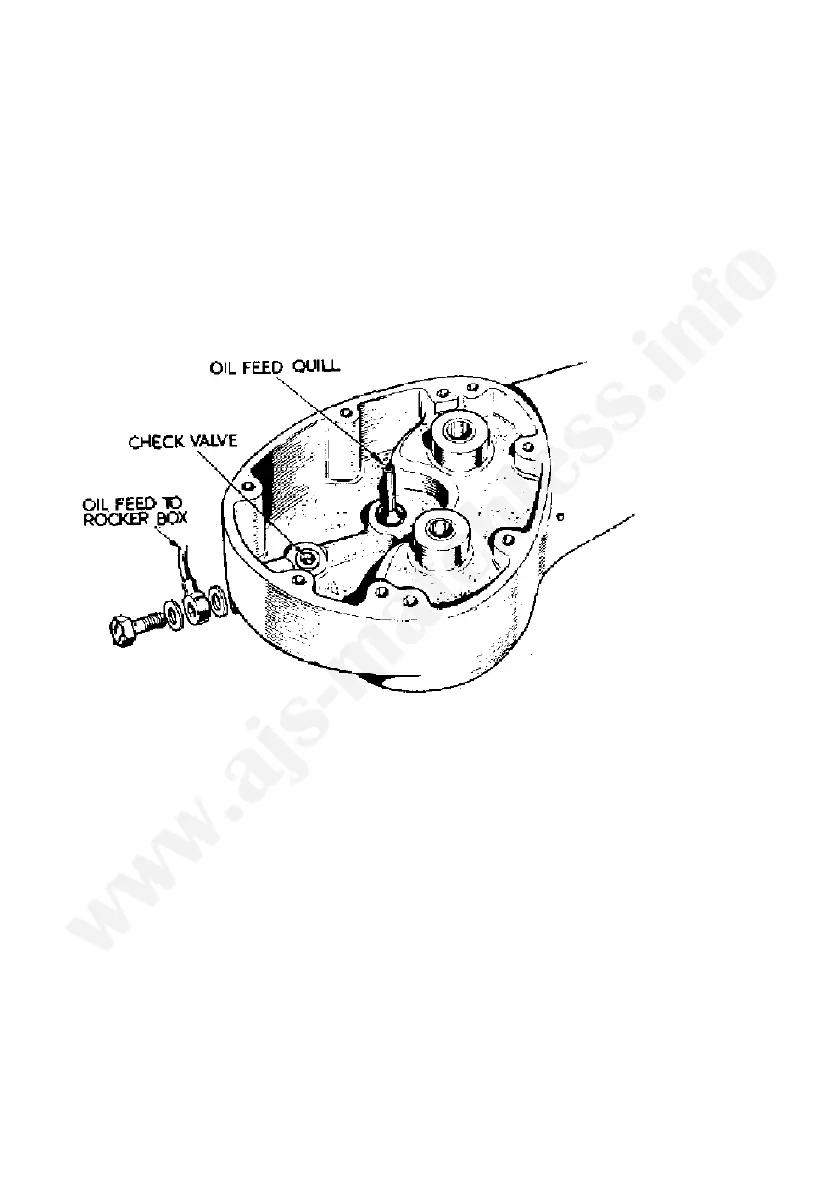

Check valve. A simple check valve (Fig. 11) is provided to prevent oil

seeping into the crankcase when the engine is stationary.

The bearing oil seal. A thin bronze bush is used in the timing side crank-

case, this does not constitute a bearing as it is simply an oil seal to stop

oil leaking past the roller bearing. 1964 models only.

Crankcase bearings. The design of the driving side bearings is unaltered.

Details for removal as described for earlier models still apply. A flanged

type roller bearing is now used in the timing side of the engine on all

single cylinder engines. The bearing sleeve is an interference fit in the

crankcase, to take it out the crankcase must be gently heated, then the

action of dropping the case on to a flat wood bench will dislodge the

sleeve.

Separating the crankcase. First take off the oil pump worm drive nut

which has a left hand thread. Take off the oil pump, retained by two nuts.

Remove the small timing pinion, which now has a parallel bore. With all

the bolts passing through the crankcase taken out the case can be parted,

the inner member for the roller bearing will remain on its shaft.

The flywheels. To take off the, inner member for the roller bearing use

two taper steel wedges behind the bearing, once a gap is formed a puller

can be used to extract the bearing member from its shaft.

FIG 11 Oil check valve

51

Loading...

Loading...