12

244/244OS Series Tooling Alcoa Fastening Systems

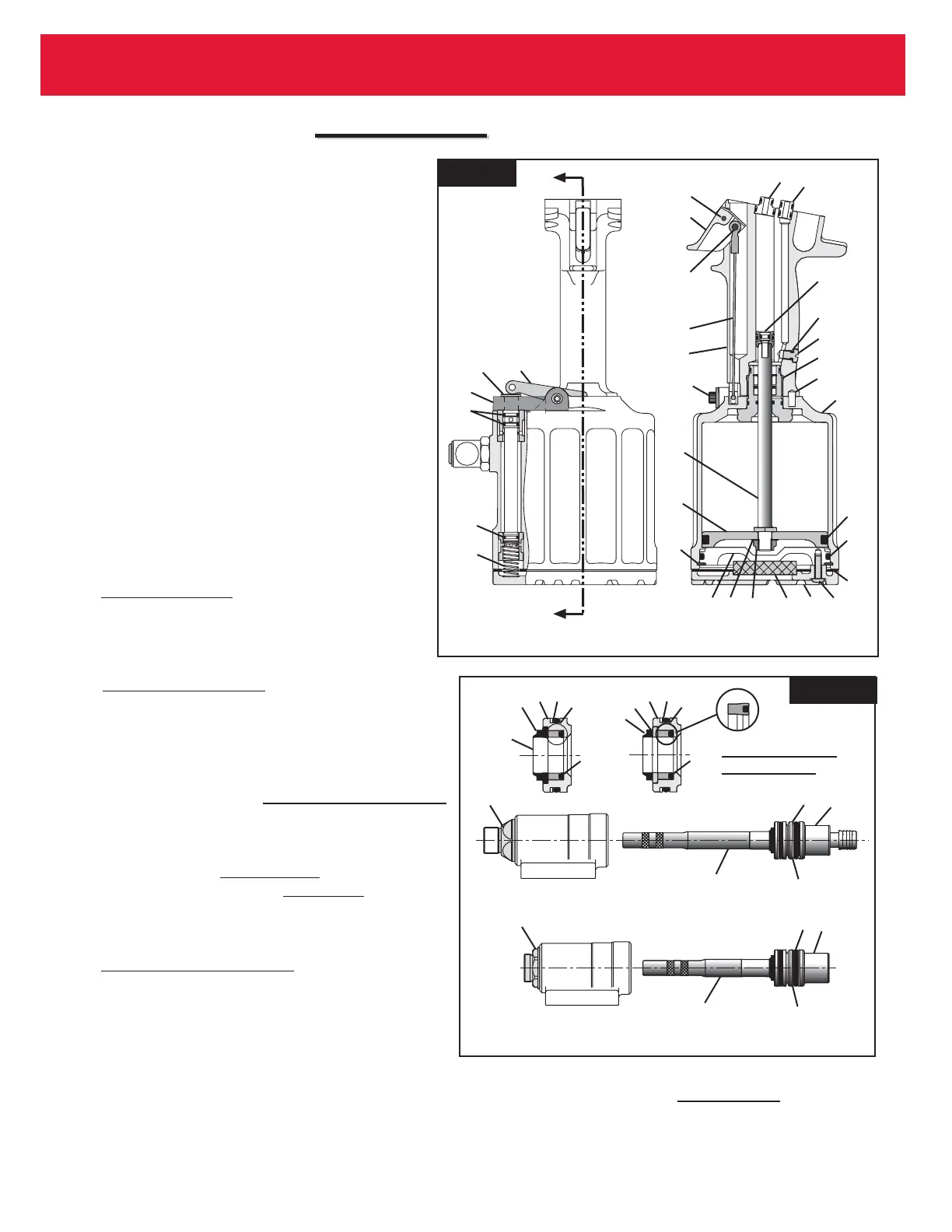

12. If Seat Assembly (80) is being replaced, push

seat and seal assembly in using soft drift. Take

care not to damage ball seat surface. (Fig. 9)

13. Assemble hydraulic Piston (18) with new seals

(16,17). Lubricate with LUBRIPLATE or

PARKER SUPER-O-LUBE. (Fig. 9)

14. Install Nose Adapter (9) on front of head. (Use

VIBRA-TITE Huck P/N 505125 on threads).

Torque to 50-60 ft. lbs. (Fig. 7)

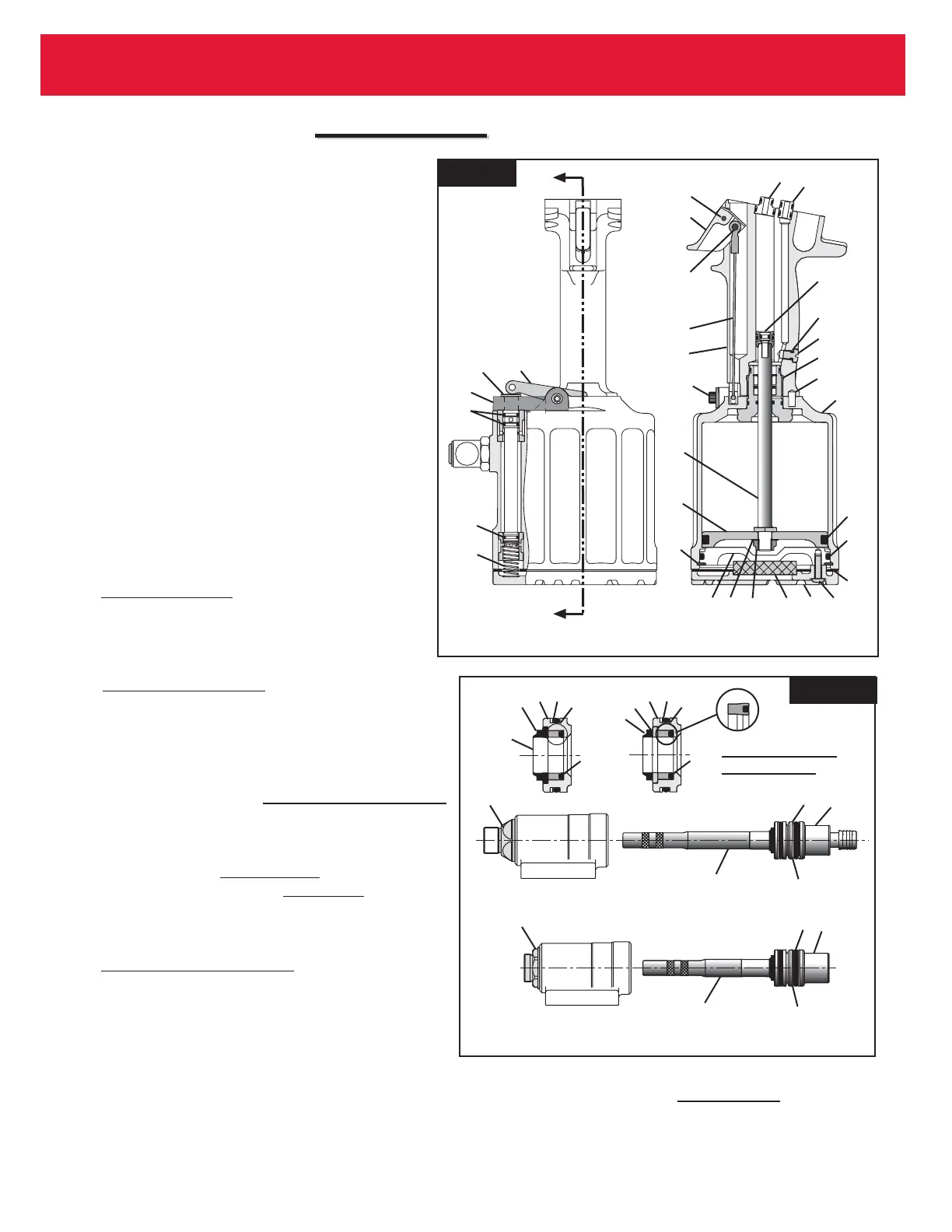

15. Assemble Front Gland (12) Gland Cap (11) O-ring

(14) Back-up Ring (13) and Polyseal (6). Thread

Piston Assembly Tool 123111-2 (244), 123111-8

(244OS) onto Piston (18). Slide complete Front

Gland Assembly and (Wiper Seal (10) 244 only)

over Piston Assembly Tool onto Piston. (Fig. 7)

16. Press entire piston and gland assembly into

head. Remove Piston Assembly Tool from

piston. (Fig. 7)

17. 244 Model: (Fig. 9)

Place Seals (20) and (24) on Rear Gland (19).

Push complete assembly into head and screw

in End Cap (21), and torque to 50 - 60 ft. lbs.

244OS Model: (Fig. 10)

Place seals (20 & 24) on Rear Gland (19). Push

complete assembly into head and screw in End

Cap (21), torque to 50-60 ft. lbs. Thread Stop (89)

into End Cap (21) two turns, thread Locknut (92)

onto Piston Stop (89) and leave loose. For

adjustment, refer to M

EASURING TOOL STROKE

section of this manual (Page 20).

18. Install Quad-Ring (72) and Spacer. Slide Reservoir

Plunger (73) in. {244OS Model:

Install Spring (93)

first, then Spring (71); 244 Model: Install two

Springs (71)}. Screw Housing/Spacer Assembly

into head. (Fig. 1)

19. 244 Model Only (Fig. 1 & 9)

Push Pintail Deflector (22) onto rear of Piston (18).

20. Place O-ring (39) on Plug (40) and screw

assembly into Handle (1). (Fig. 6)

21. Install Pull (29) and Return (25) Gland Assemblies in

handle. Push head down on glands. Place tool in a

vise Head down and install 4 Screws (69) and torque

to 170 inch pounds. (Fig. 6 & 9)

22. Tool is now completely assembled except for relief

and check valves. See F

ILL AND BLEED

procedure for

replacement of valve components.

Fig. 7a

Fig. 7b

Loading...

Loading...