14

244/244OS Series Tooling Alcoa Fastening Systems

Step 5

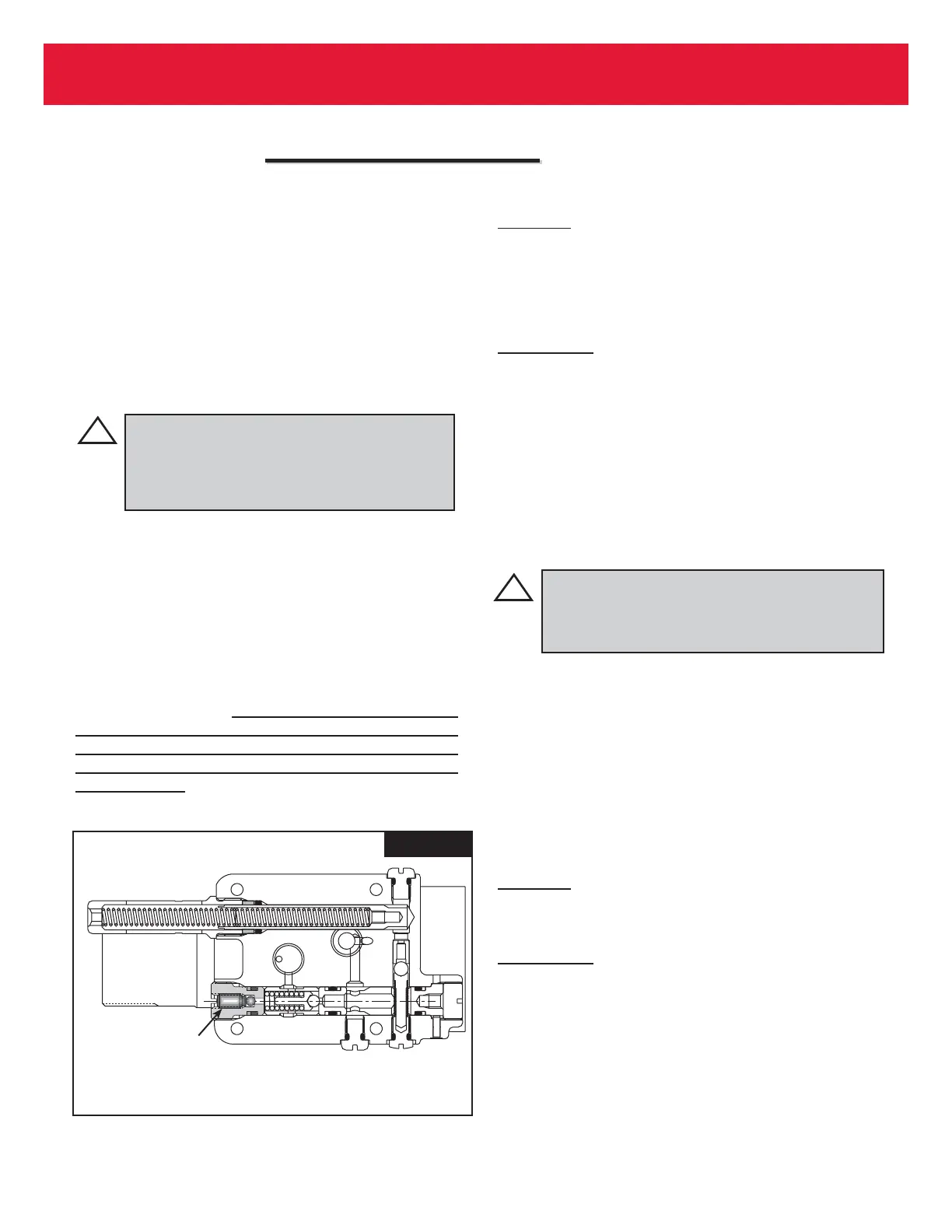

Install fill bottle in head fill port (check Valve hole) (See

Fig. 8).

Step 6

Connect tool to shop air 20 to 40 psi. Cycle tool 20-30

times, watch for air bubbles escaping from the tool into

bottle. (You may rock the tool to free trapped air in the

tool.) Do not allow the air to re-enter the tool. When

cycling tool, always hold bottle up as shown in Figure 8

to prevent drawing in air from empty part of bottle.

Step 7

When air bubbles no longer appear in bottle, remove fill

bottle while tool is lying on its side.

Step 8

Install the check valve Ball (75), Check Valve Guide (76)

and Spring (77). Replace the Plug (78).

Step 9

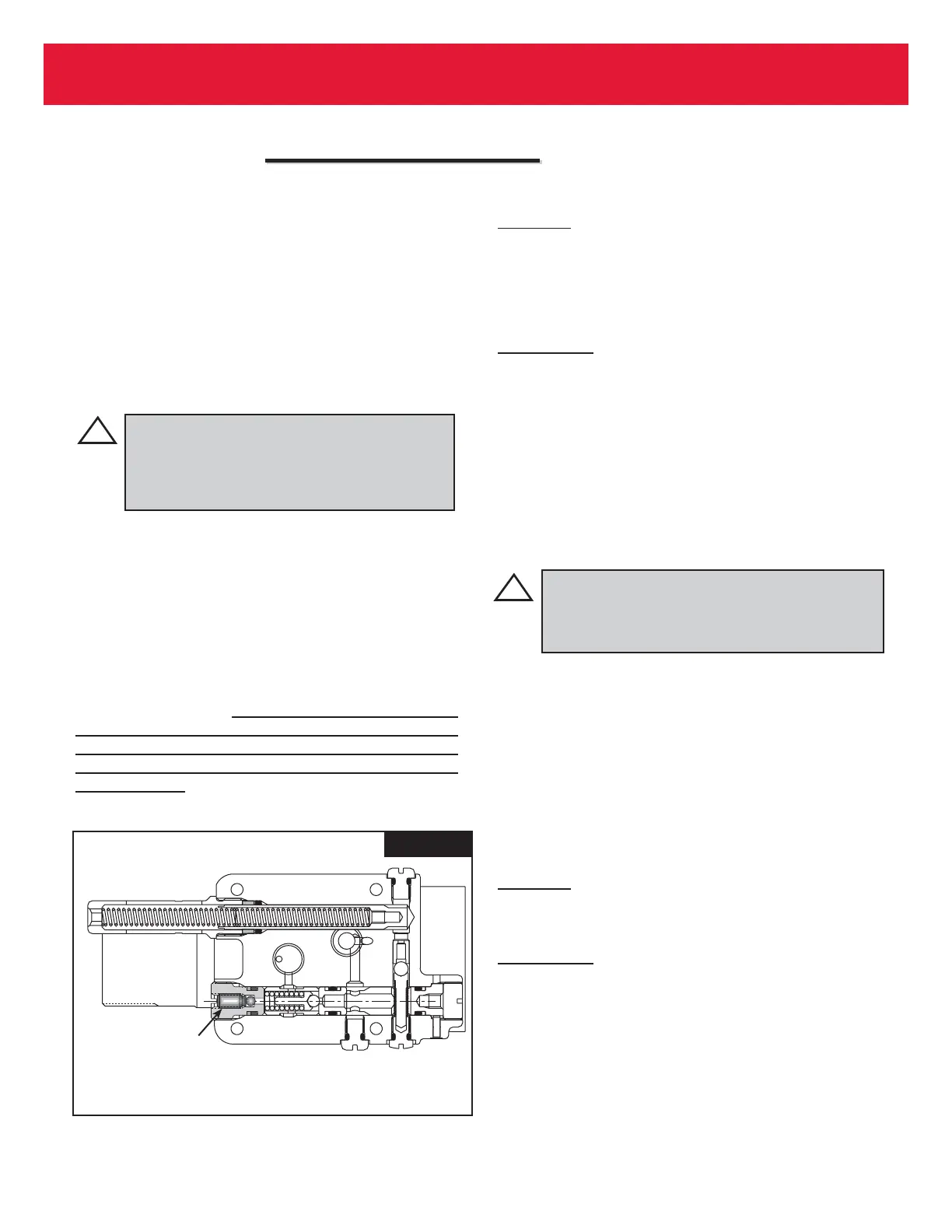

Turn tool so front of head faces you and remove the

relief valve Plug (85). Prior to removing Plug (85), it is

advisable to back out setscrew inside of plug by

approximately 1/2 turn counterclockwise. (See Figure

8a). This ensures that the Piston will remain in full-

forward position. Install relief valve Ball (81), Guide (82),

Sleeve (83) and Spring (84). Replace the Plug (85).

Step 10

244 Model

(Fig. 8)

Unlock Fill Tool and check Reservoir red line. At this

point cycle the tool the with Stall Nut attached and

retaining nut locked in the full forward position (“Dead

Stall”). Reservoir should not drop below the red line on

the reservoir housing.

244OS Model

(Fig. 8)

Unlock Fill Tool and check Reservoir red line. At this

point cycle the tool with the Stop still holding the piston

in the full forward position (“Dead Stall”). Reservoir

should not drop below the red line on the reservoir

housing.

Step 11

Re-lock the fill tool. Lay tool on its left side and remove

Plug (40). Top off reservoir by placing a few drops of oil

in hole and waiting for air bubbles to escape. Push a pin

or a scribe into hole to check for trapped air bubbles.

Replace plug.

Step 12

Unlock the fill tool and cycle tool as in step 10.

Reservoir may drop slightly. If so, repeat step 11 until

when you touch the fill tool handle, it has no pressure

against it and it drops out of the lock position, and the

plunger does not drop when tool is cycled. NOTE: This

usually requires 3 to 4 times topping off.

Step 13

244 Model

(Fig. 8)

Remove fill tool and stall nut. Install a nose assembly

and pull several fasteners to test function.

244OS Model (Fig. 8)

Remove fill tool. Adjust the tools stroke for the Nose

Assembly being used by threading out Piston Stop (89).

Refer to Measuring Tool Stroke section for the stroke

adjustment procedure.

WARNING - Failure to re-lock the fill tool will

result in oil being ejected from the head under

pressure during the topping off of the

reservoir. Severe personal injury may result.

WARNING: Air pressure MUST be set to 20

to 40 psi to prevent possible injury from

high pressure spray. If plug (78) is

removed, fill bottle must be in place before

cycling tool.

approx. 1/2 turn.

Loading...

Loading...