no sound of escaping steam is coming through

the control valve. NEVER ATTEMPT TO OPEN

THE STERILIZER UNTIL THE GAUGE READS

ZERO.

12. With the pressure gauge reading 0 PSI

loosen the wing nuts evenly by turning two

opposite wing nuts counter clockwise. The

wing nuts may still be hot. We recommend

wearing heat resistant gloves to avoid potential

burns. With the wing nuts removed, remove

the cover by turning it counter clockwise.

Remember when removing the cover always tilt

and angle the cover away from yourself or

other people to prevent injury from any

remaining steam in the chamber. PLEASE

NOTE, when the sterilizer is allowed to cool

with the cover tightened to the bottom this

increases the chance that the cover may

become stuck to the bottom.

13. With the cover removed the inner container

may now be removed. In the event that the

inner container remains hot, we recommend

using heat resistant gloves to handle the inner

container. If the sterilizer is not going to be

immediately used again, before storing the unit

all water should be emptied from the unit and

the inside be thoroughly dried. We

recommend pouring the water out of the unit

while it is still warm and leaving the cover off to

let the inside of the chamber dry. The residual

heat will help dry the unit. For storage, place

the cover on the unit and loosely attach the

wing nuts. We recommend leaving the control

valve open (See Fig. 2) to allow air to circulate

through your sterilizer.

14. We have included a sterilization log sheet

that we highly recommend using as best

practice. The sheet will allow the operator to

keep a record of all of the sterilization cycles.

The operator should diligently fill out and keep

the record safe. Additional sheets can be

downloaded for free at our website.

MAINTENANCE

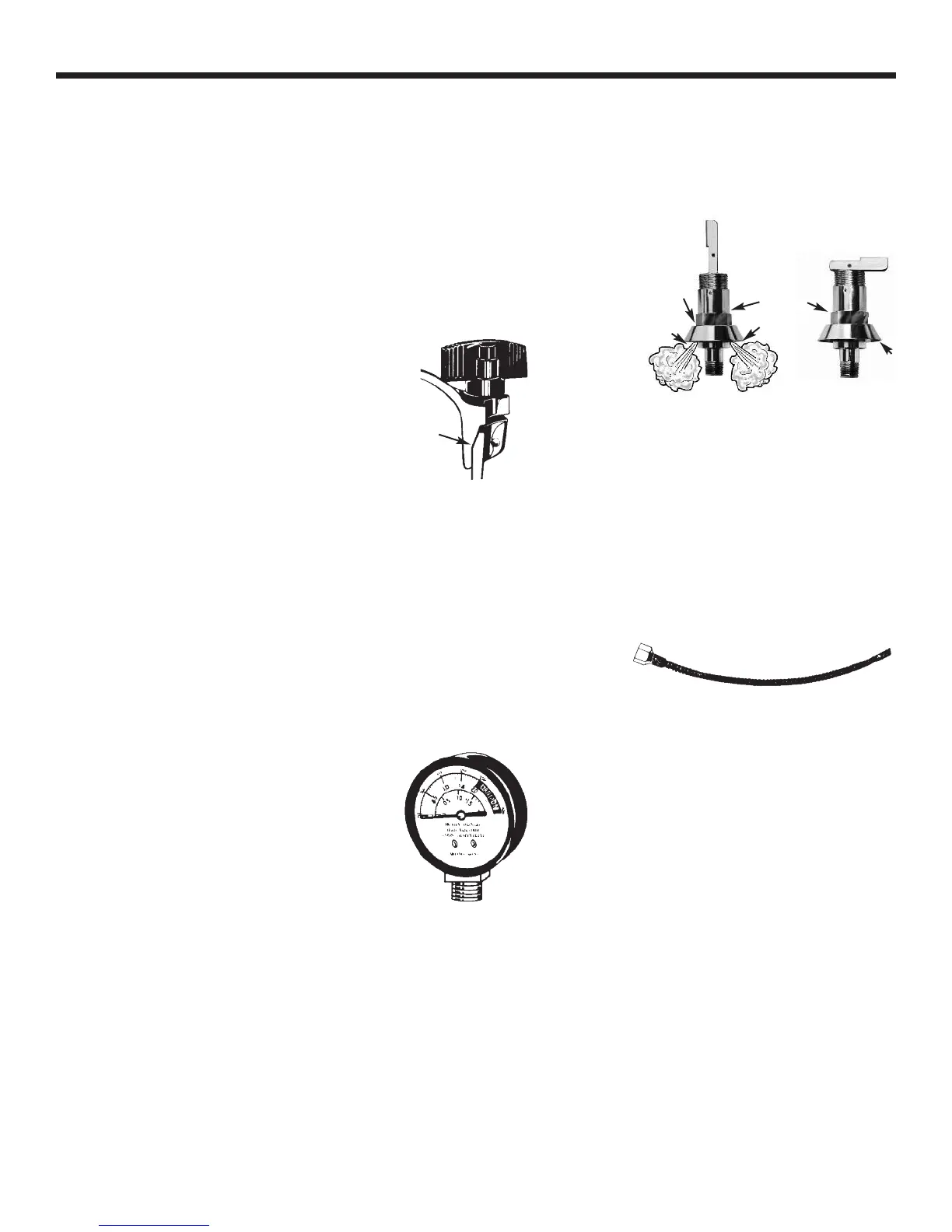

1. Metal-to-Metal seal (See Fig. 1). We

recommend periodically checking the metal-

to-metal seal and lubricating as needed. It is

extremely important to keep the seal lubricated

as failure to do so could cause the cover to

stick potentially making it very difficult to

remove the cover.

2. PRESSURE GAUGE, PART NO. 72S. (See

Fig. 4) Do not immerse your pressure gauge in

water when cleaning the unit. The gauge does

not require any maintenance other than

periodically making sure that the opening of the

gauge on the underside of the cover is open

and free of any foreign matter. DO NOT USE

YOUR UNIT IF THE GAUGE FACE CRACKS,

FILLS WITH STEAM OR DOES NOT RETURN

TO ZERO.

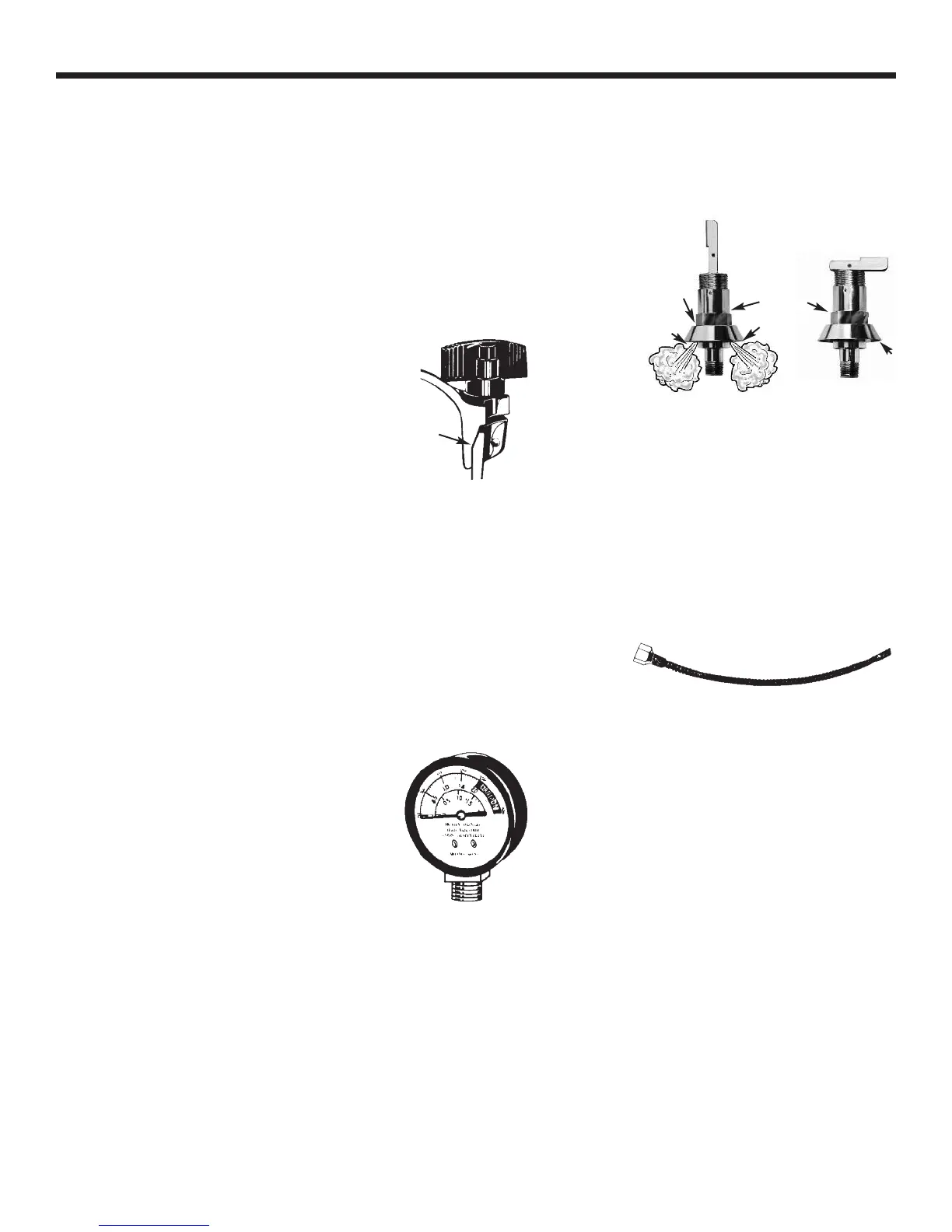

3. CONTROL VALVE, PART NO. 65K (See Fig.

2 & 3). To ensure long life and proper

operation it is important to periodically clean

the control valve thoroughly in hot soapy water.

If distilled water is not used, calcification could

build up and cause the valve to leak. To clean

any built up calcification, put the lever in the

open position and soak the valve in vinegar. Be

sure to clean the control valve in hot soapy

water after soaking in vinegar.

In the event that you are unable to

properly remove any foreign material from your

control valve, we recommend that the control

valve be discarded and replaced with a new

control valve.

4. AIR EXHAUST TUBE, PART NO. 2155 (See

Fig. 5). It is essential that the air exhaust tube

be frequently checked to make sure that air

passes freely through it. We recommend that

you blow air through the exhaust tube at least

once a month to make certain that it is not

plugged with any foreign material. Simply

remove the air exhaust tube from the control

valve on the bottom of the sterilizer cover. The

tube may be cleaned by using a small diameter

wire running through the length of the tube

several times. If you notice any difficulty

cleaning the air exhaust tube or notice any

corrosion on the inside of the passage, we

recommend that you discard the tube and

replace it with a new one.

5. EXCESS PRESSURE RELIEF VALVE, PART

NO. 2050K (See Fig. 6). Your sterilizer is

equipped with a new type of excess pressure

relief valve. It is designed for longer, mainte-

nance free service; however, we recommend

that the valve be replaced every three years in

normal service. The valve is designed to

5

Fig. 4

Pressure Gauge

Fig. 1

Metal-to-metal seal

Apply lubricant here

Open control valve Closed control valve

Fig. 2 Fig. 3

Lever horizontal

o

r closed

L

ever vertical

or open

s

team escape

h

oles

steam escape

holes

valve body

deflector

d

eflector

Fig. 5

Loading...

Loading...