Paragraphs 211B-213

ALLiS-CHALMERS

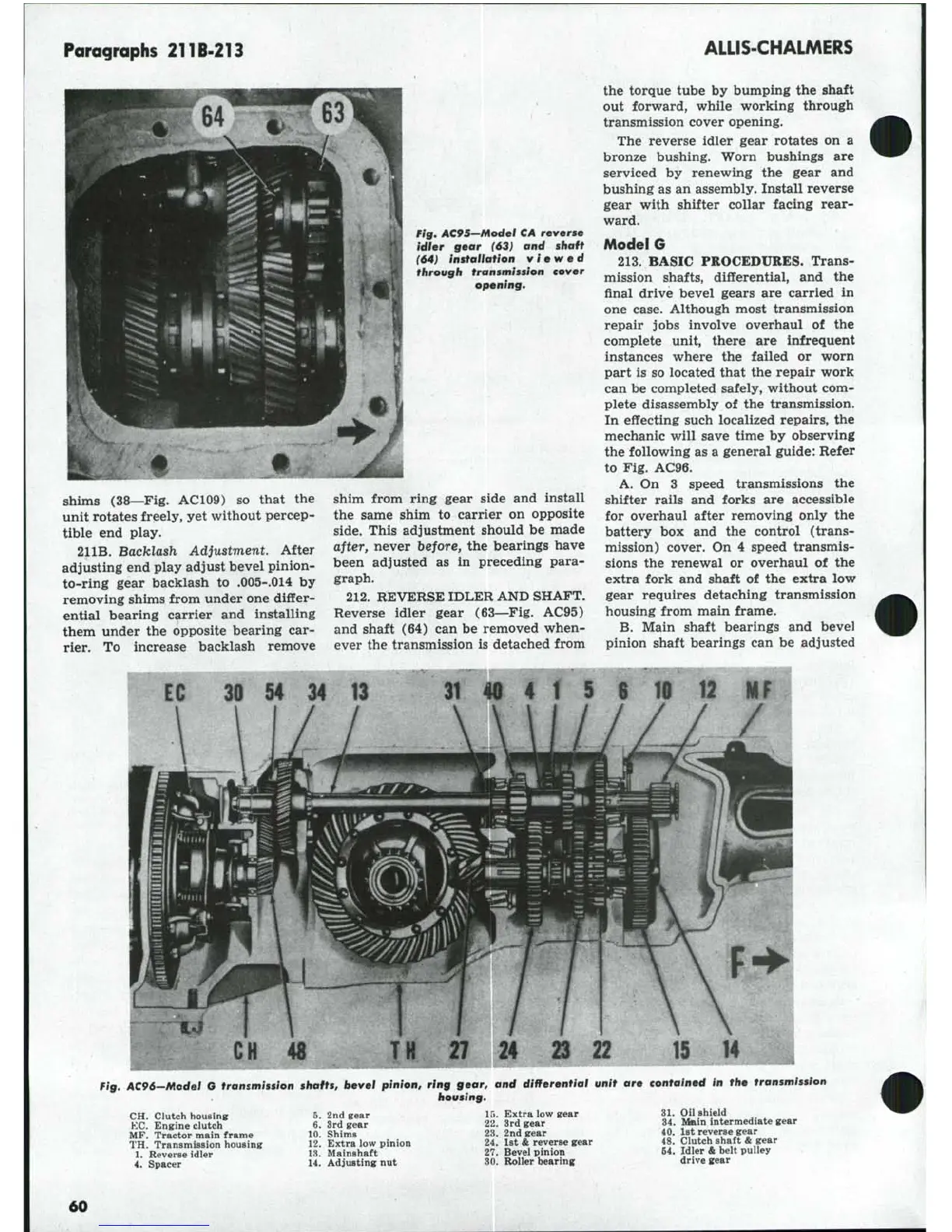

¥ig. AC95-Model CA reverse

idler gear (63) and shaft

(64) installation viewed

through transmission cover

opening.

shims (38—Fig. AC109) so that the

unit rotates freely, yet without percep-

tible end play.

211B.

Backlash Adjustment. After

adjusting end play adjust bevel pinion-

to-ring gear backlash to .005-.014 by

removing shims from under one differ-

ential bearing carrier and installing

them under the opposite bearing car-

rier. To increase backlash remove

shim from ring gear side and install

the same shim to carrier on opposite

side.

This adjustment should be made

after, never before, the bearings have

been adjusted as in preceding para-

graph.

212.

REVERSE IDLER AND SHAFT.

Reverse idler gear (63—Fig. AC95)

and shaft (64) can be removed when-

ever the transmission is detached from

the torque tube by bumping the shaft

out forward, while working through

transmission cover opening.

The reverse idler gear rotates on a

bronze bushing. Worn bushings are

serviced by renewing the gear and

bushing as an assembly. Install reverse

gear with shifter collar facing rear-

ward.

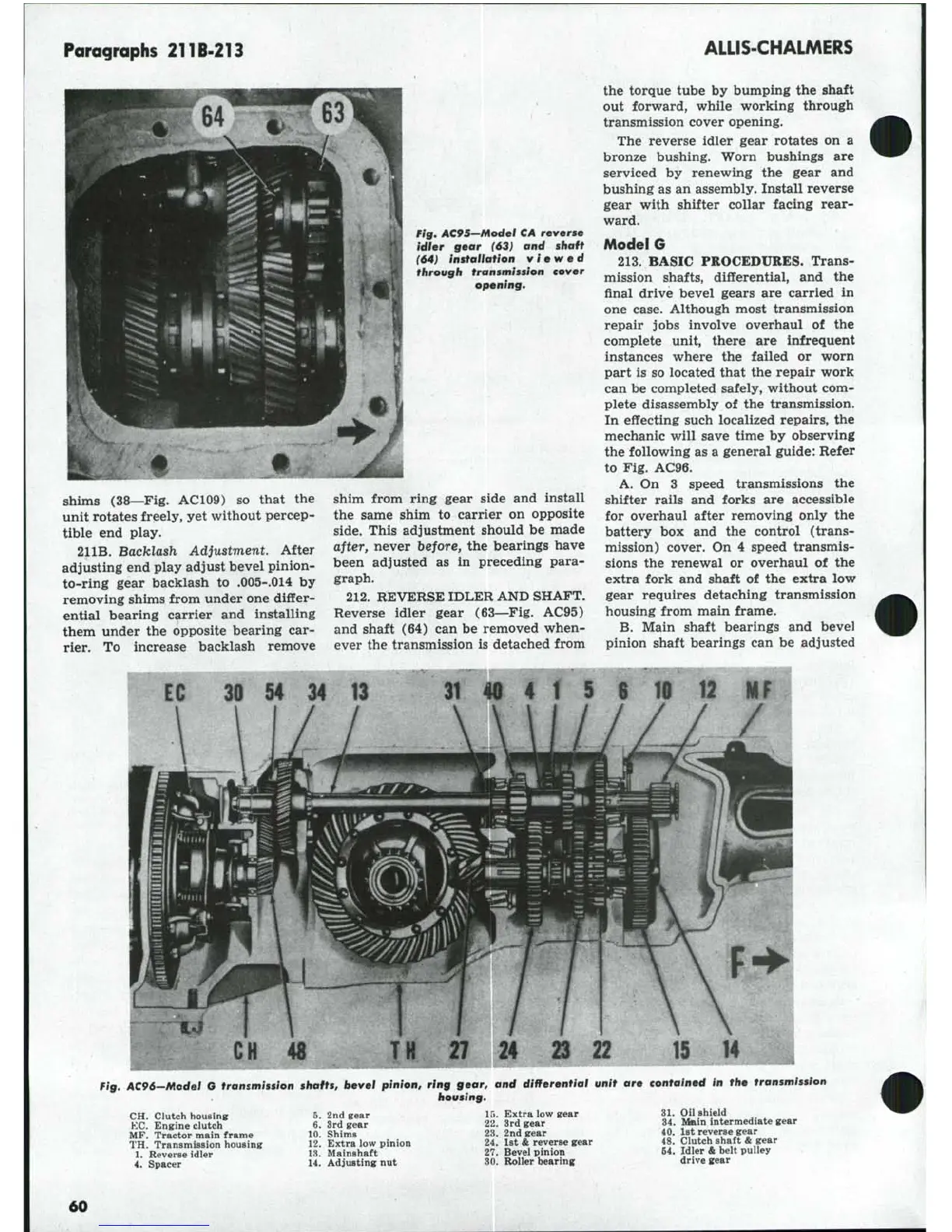

Model G

213.

BASIC PROCEDURES. Trans-

mission shafts, differential, and the

final drive bevel gears are carried in

one case. Although most transmission

repair jobs involve overhaul of the

complete unit, there are infrequent

instances where the failed or worn

part is so located that the repair work

can be completed safely, without com-

plete disassembly of the transmission.

In effecting such localized repairs, the

mechanic will save time by observing

the following as a general guide: Refer

to Fig. AC96.

A. On 3 speed transmissions the

shifter rails and forks are accessible

for overhaul after removing only the

battery box and the control (trans-

mission) cover. On 4 speed transmis-

sions the renewal or overhaul of the

extra fork and shaft of the extra low

gear requires detaching transmission

housing from main frame.

B.

Main shaft bearings and bevel

pinion shaft bearings can be adjusted

30

54 34 13

3V

40 4 1 S S ie 12 MF

CH

48

T

M

27 24

Fig, AC96-Modet G transmission shafts, bevel pinion, ring gear, and differential unit are contained in the transmission

housing.

CH. Clutch housing

KC.

Engine clutch

MF.

Tractor main frame

TH.

Transmission housing

1.

Reverse idler

4.

Spacer

5.

2nd gear

6. 3rd gear

10.

Shims

12.

Extra low pinion

13.

Mainshaft

14.

Adjusting nut

15.

Extra low gear

22.

Brd gear

23.

2nd gear

24.

1st

&

reverse gear

27.

Bevel pinion

30.

Roller bearing

31.

Oil shield

34.

Main intermediate gear

40.

1st reverse gear

48.

Clutch shaft

&

gear

64.

Idler

&

helt pulley

drive gear

60

Loading...

Loading...