ALLIS-CHALMERS

Paragraphs 214-218

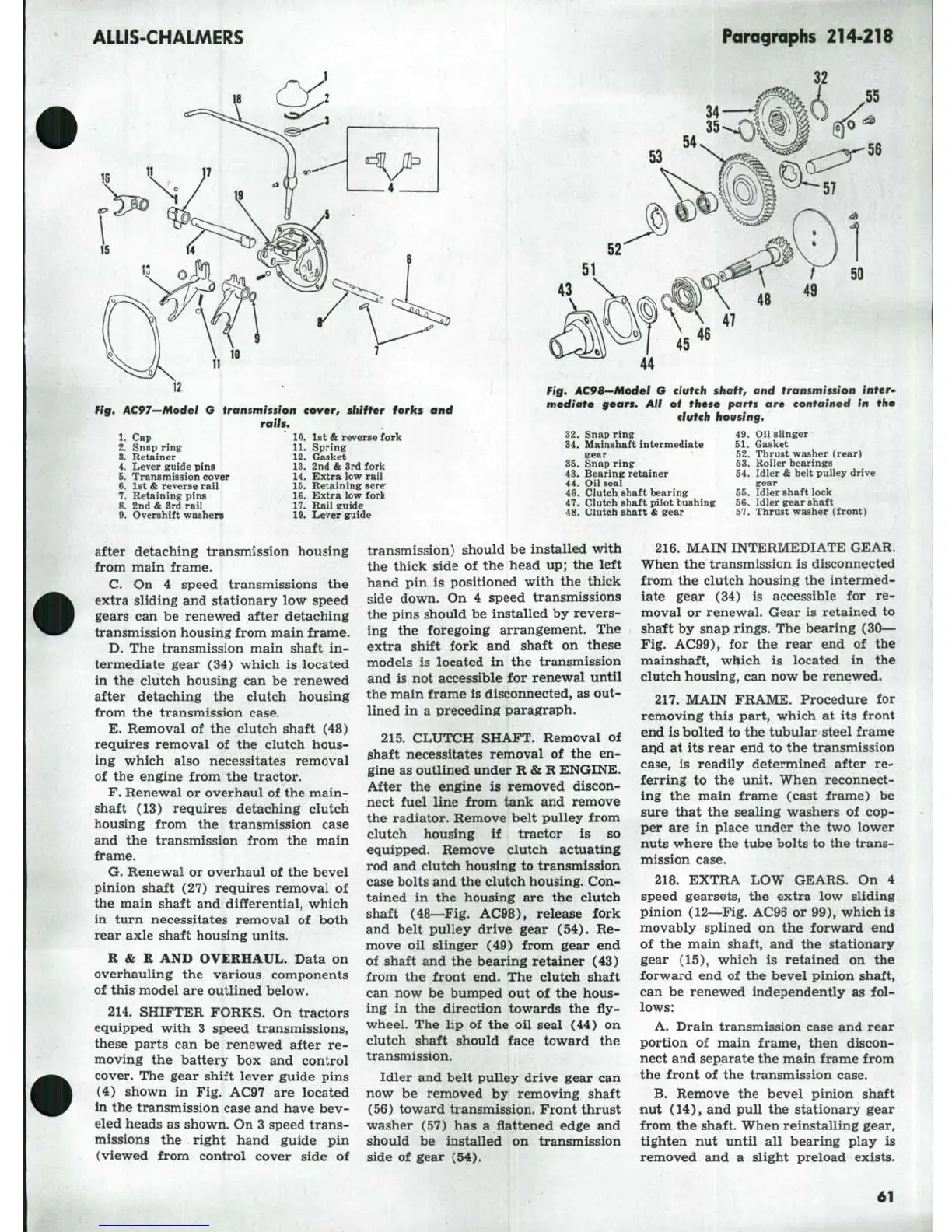

Fig, ilC97—Model 6 transmission

cover,

shifter forks and

rath.

10.

lst

&

reverse fork

11.

Spring

12.

Gasket

13.

2nd

&

3rd fork

14.

Extra low rail

15.

Retaining sere

16.

Extra low fork

17.

Rail guide

19.

Lever guide

1.

Cap

2.

Snap ring

3.

Retainer

4.

Lever guide pins

5.

Transmission cover

6. 1st & reverse rail

7.

Retaining* pins

8. 2nd & 3rd rail

9. Overshift washen

34

53

50

49

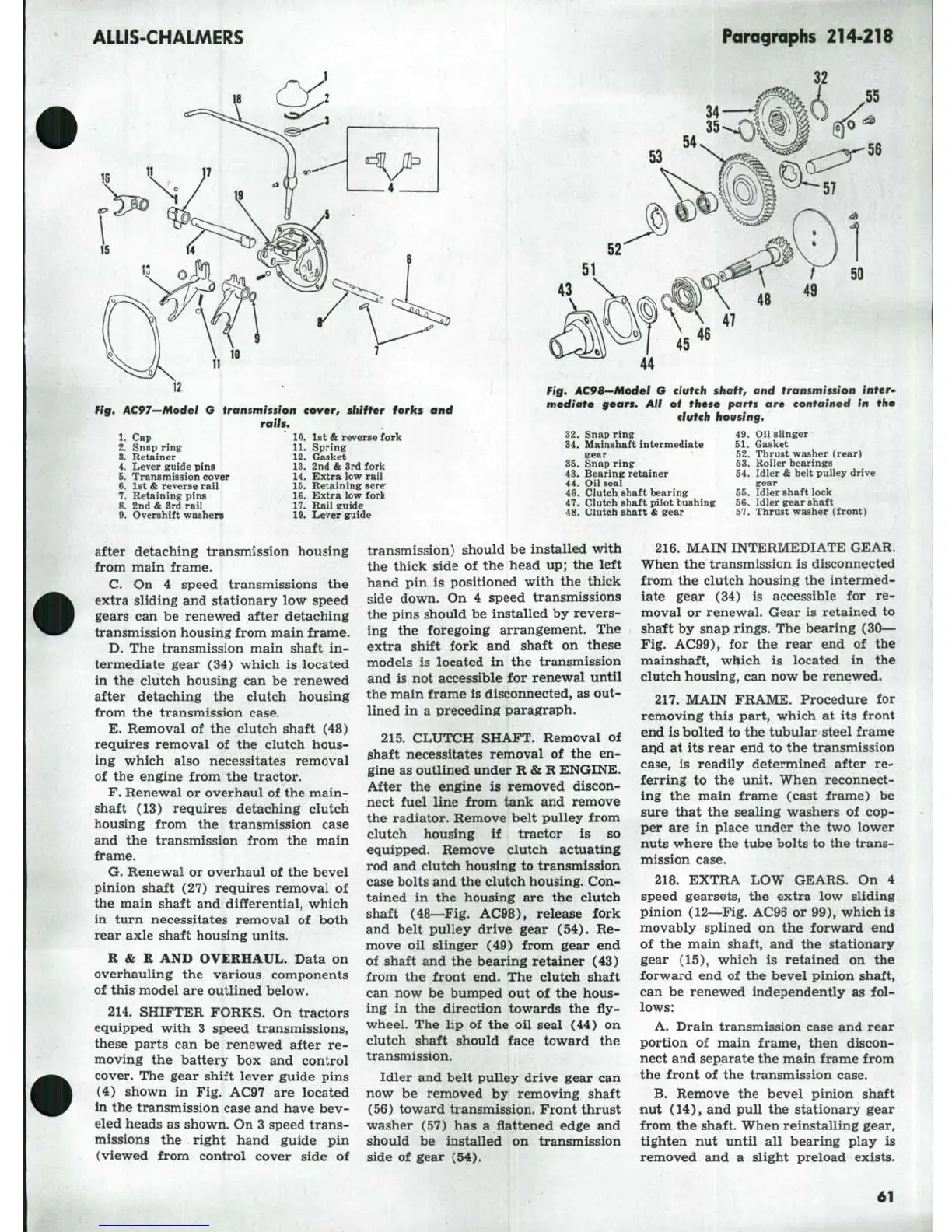

Fig, AC9<—Model G clutch

shaft,

and transmission

inter-

mediate gears. All of these parts are contained in the

clutch housing.

32.

Snap ring

34.

Mainahaft intermediate

gear

35.

Snap ring

43.

Bearing retainer

44.

Oil seal

46.

Clutch shaft bearing

47.

Clutch shaft pilot bushing

48.

Clutch shaft

&

gear

49.

Oil Blinger

51.

Gasket

52.

Thrust washer (rear)

53.

Roller bearings

54.

Idler & belt pulley drive

gear

55.

Idler shaft lock

56.

Idler gear shaft

57.

Thrust washer (front)

after detaching transmission housing

from main frame.

C.

On 4

speed transmissions

the

extra sliding and stationary

low

speed

gears

can be

renewed after detaching

transmission housing from main frame.

D.

The

transmission main shaft

in-

termediate gear

(34)

which

is

located

in

the

clutch housing

can be

renewed

after detaching

the

clutch housing

from

the

transmission case.

E.

Removal

of the

clutch shaft

(48)

requires removal

of the

clutch hous-

ing which also necessitates removal

of

the

engine from

the

tractor.

F. Renewal or overhaul

of

the main-

shaft

(13)

requires detaching clutch

housing from

the

transmission case

and

the

transmission from

the

main

frame.

G. Renewal

or

overhaul

of

the bevel

pinion shaft

(27)

requires removal

of

the main shaft

and

differential, which

in turn necessitates removal

of

both

rear axle shaft housing units.

R&R AND OVERHAUL. Data

on

overhauling

the

various components

of this model are outlined below.

214.

SHIFTER FORKS.

On

tractors

equipped with

3

speed transmissions,

these parts

can be

renewed after

re-

moving

the

battery

box and

control

cover.

The

gear shift lever guide pins

(4) shown

in Fig.

AC97

are

located

in the transmission case and have bev-

eled heads as shown. On 3 speed trans-

missions

the

right hand guide

pin

(viewed from control cover side

of

transmission) should

be

installed with

the thick side

of the

head up;

the

left

hand

pin is

positioned with

the

thick

side down.

On 4

speed transmissions

the pins should

be

installed

by

revers-

ing

the

foregoing arrangement.

The

extra shift fork

and

shaft

on

these

models

is

located

in the

transmission

and

is not

accessible

for

renewal until

the main frame is disconnected, as out-

lined

in a

preceding paragraph.

215.

CLUTCH SHAFT. Removal

of

shaft necessitates removal

of the en-

gine as outlined under R&R ENGINE.

After

the

engine

is

removed discon-

nect fuel line from tank

and

remove

the radiator. Remove belt pulley from

clutch housing

if

tractor

is so

equipped. Remove clutch actuating

rod and clutch housing

to

transmission

case bolts and the clutch housing. Con-

tained

in the

housing

are the

clutch

shaft (48—Fig. AC98), release fork

and belt pulley drive gear

(54). Re-

move

oil

slinger

(49)

from gear

end

of shaft and

the

bearing retainer

(43)

from

the

front

end. The

clutch shaft

can

now be

bumped

out of the

hous-

ing

in the

direction towards

the fly-

wheel.

The lip of the oil

seal

(44) on

clutch shaft should face toward

the

transmission.

Idler and belt pulley drive gear

can

now

be

removed

by

removing shaft

(56) toward transmission. Front thrust

washer

(57) has a

flattened edge

and

should

be

installed

on

transmission

side

of

gear

(54).

216.

MAIN INTERMEDIATE GEAR.

When

the

transmission

is

disconnected

from

the

clutch housing

the

intermed-

iate gear

(34) is

accessible

for re-

moval

or

renewal. Gear

is

retained

to

shaft

by

snap rings. The bearing (30—

Fig. AC99),

for the

rear

end of the

mainshaft, which

is

located

in the

clutch housing, can now be renewed.

217.

MAIN FRAME. Procedure

for

removing this part, which

at its

front

end is bolted to the tubular steel frame

and

at its

rear end

to

the transmission

case,

is

readily determined after

re-

ferring

to the

unit. When reconnect-

ing

the

main frame (cast frame)

be

sure that

the

sealing washers

of cop-

per

are in

place under

the two

lower

nuts where the tube bolts to the trans-

mission case.

218.

EXTRA

LOW

GEARS.

On 4

speed gearsets,

the

extra

low

sliding

pinion (12—Fig. AC96

or

99), which

is

movably splined

on the

forward

end

of

the

main shaft,

and the

stationary

gear

(15),

which

is

retained

on the

forward

end of the

bevel pinion shaft,

can

be

renewed independently

as fol-

lows:

A. Drain transmission case and rear

portion

of

main frame, then discon-

nect and separate the main frame from

the front

of the

transmission case.

B.

Remove

the

bevel pinion shaft

nut (14),

and

pull

the

stationary gear

from the shaft. When reinstalling gear,

tighten

nut

until

all

bearing play

is

removed

and a

slight preload exists.

61

Loading...

Loading...