Paragraphs 219-226

ALLIS-CHALMERS

16

19

18 17

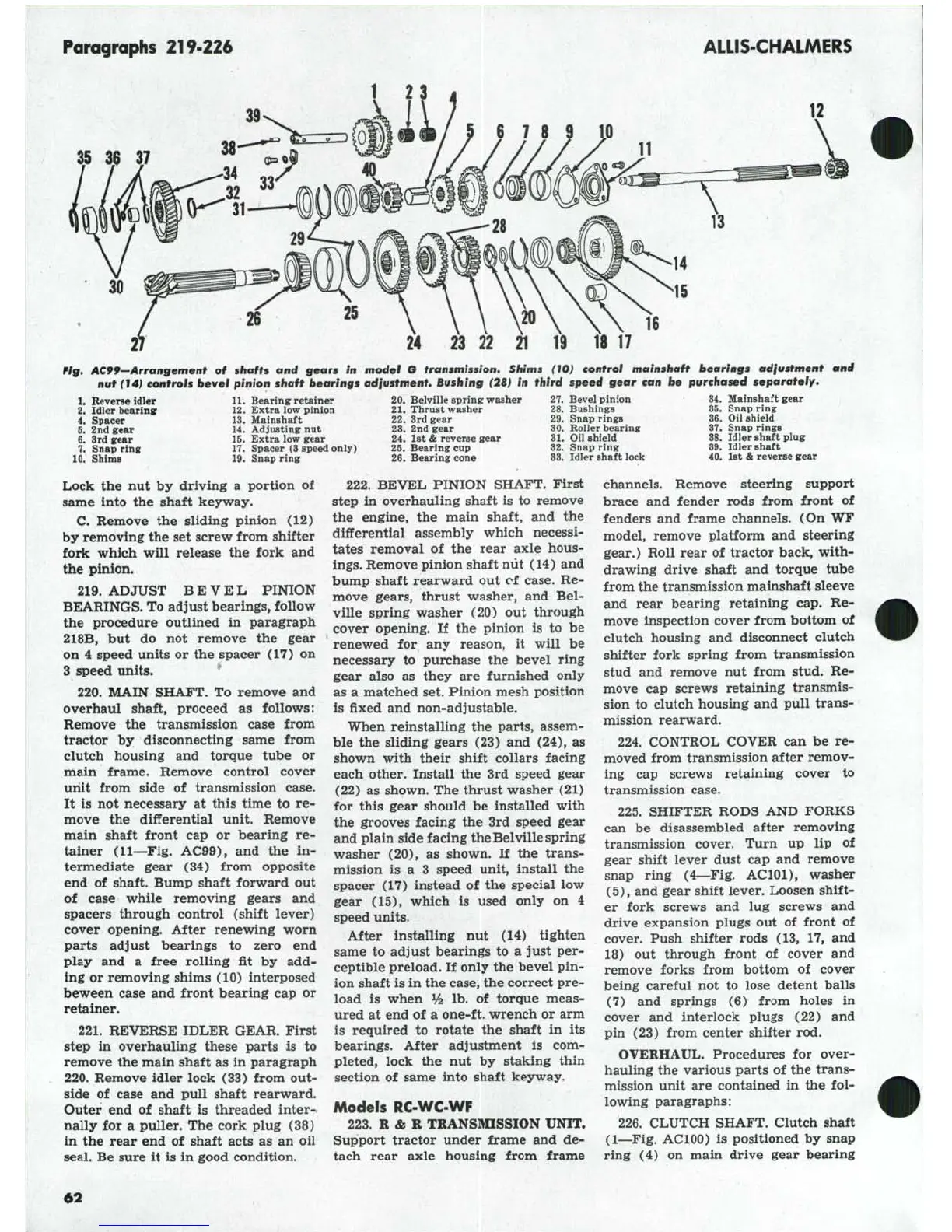

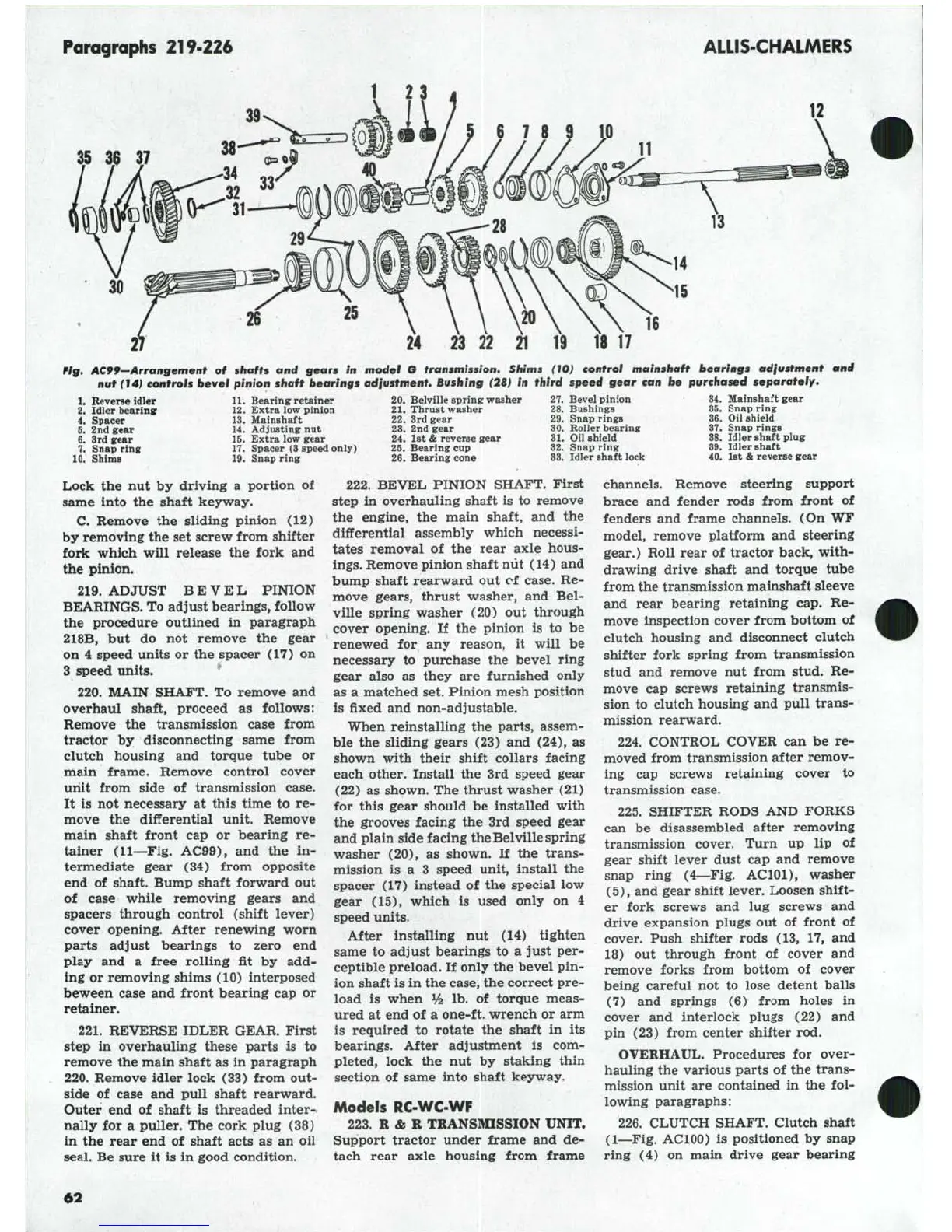

Pig, AC99-Arrangement of shafts and gears In model O transmission. Shims (10} control mainshaft bearings adiustment and

nut (14)

controls

bevel pinion shaft bearings adiustment.

Bushing

(28) in third speed gear can be purchased separately.

1.

Reverse idler

2.

Idler hearing

4.

Spacer

6. 2nd gear

6. Srd gear

7. Snap ring

10.

Shims

11.

Bearing retainer

12.

Extra low pinion

13.

Mainshaft

14.

Adjusting

nut

15.

Extra low gear

17.

Spacer

(3

speed only)

19.

Snap ring

20.

Belville spring washer

21.

Thrust washer

22.

3rd gear

23.

2nd gear

24.

1st

& reverse uewr

25.

Bearing cup

26.

Bearing cone

27.

Bevel pinion

28.

Bushings

29.

Snap rings

30.

Roller hearing

31.

Oil shield

32.

Snap ring

83.

Idler Bhaft lock

34.

Mainshaft gear

36.

Snap ring

36.

Oil shield

87.

Snap rings

88.

Idler shaft plug

39.

Idler shaft

40.

let

& reverse gear

Lock

the nut by

driving

a

portion

of

same into

the

shaft

C.

Remove

the

sliding pinion

(12)

by removing the set screw from shifter

fork which will release

the

fork

and

the pinion.

219.

ADJUST BEVEL PINION

BEARINGS. To adjust bearings, follow

the procedure outlined

in

paragraph

218B,

but do not

remove

the

gear

on

4

speed units or the spacer

(17) on

3 speed units.

220.

MAIN SHAFT.

To

remove

and

overhaul shaft, proceed

as

follows:

Remove

the

transmission case from

tractor

by

disconnecting same from

clutch housing

and

torque tube

or

main frame. Remove control cover

unit from side

of

transmission case.

It

is not

necessary

at

this time

to re-

move

the

differential unit. Remove

main shaft front

cap or

bearing

re-

tainer (11—Fig. AC99),

and the in-

termediate gear

(34)

from opposite

end

of

shaft. Bump shaft forward

out

of case while removing gears

and

spacers through control (shift lever)

cover opening. After renewing worn

parts adj ust bearings

to

zero

end

play

and a

free rolling

fit by add-

ing or removing shims (10) interposed

beween case and front bearing cap

or

retainer.

221.

REVERSE IDLER GEAR. First

step

in

overhauling these parts

is to

remove the main shaft as in paragraph

220.

Remove idler lock (33) from out-

side

of

case

and

pull shaft rearward.

Outer

end of

shaft

is

threaded inter-

nally

for a

puller. The cork plug

(38)

in

the

rear end

of

shaft acts

as an oil

seal. Be sure

it is in

good condition.

222.

BEVEL PINION SHAFT. First

step

in

overhauling shaft

is to

remove

the engine,

the

main shaft,

and the

differential assembly which necessi-

tates removal

of the

rear axle hous-

ings.

Remove pinion shaft nut (14) and

bump shaft rearward

out of

case.

Re-

move gears, thrust washer,

and Bel-

ville spring washer

(20) out

through

cover opening.

If the

pinion

is to be

renewed

for any

reason,

it

will

be

necessary

to

purchase

the

bevel ring

gear also

as

they

are

furnished only

as

a

matched set. Pinion mesh position

is fixed and non-adjustable.

When reinstalling

the

parts, assem-

ble

the

sliding gears

(23) and

(24),

as

shown with their shift collars facing

each other. Install

the 3rd

speed gear

(22)

as

shown. The thrust washer

(21)

for this gear should

be

installed with

the grooves facing

the

3rd speed gear

and plain side facing the Belville spring

washer

(20), as

shown.

If the

trans-

mission

is a 3

speed unit, install

the

spacer

(17)

instead

of the

special

low

gear

(15),

which

is

used only

on 4

speed units.

After installing

nut (14)

tighten

same

to

adjust bearings

to a

just per-

ceptible preload.

If

only the bevel pin-

ion shaft is in the case, the correct pre-

load

is

when

^ lb. of

torque meas-

ured

at

end

of

a one-ft. wrench or arm

is required

to

rotate

the

shaft

in its

bearings. After adjustment

is com-

pleted, lock

the nut by

staking thin

section

of

same into shaft keyway.

Models RC-WC-WF

223.

R&R

TRANSMISSION UNIT.

Support tractor under frame

and de-

tach rear axle housing from frame

channels. Remove steering support

brace

and

fender rods from front

of

fenders

and

frame channels. (On WF

model, remove platform

and

steering

gear.) Roll rear

of

tractor back, with-

drawing drive shaft

and

torque tube

from the transmission mainshaft sleeve

and rear bearing retaining

cap. Re-

move inspection cover from bottom

of

clutch housing

and

disconnect clutch

shifter fork spring from transmission

stud

and

remove

nut

from stud.

Re-

move

cap

screws retaining transmis-

sion

to

clutch housing and pull trans-

mission rearward.

224.

CONTROL COVER

can be re-

moved from transmission after remov-

ing

cap

screws retaining cover

to

transmission case.

225.

SHIFTER RODS AND FORKS

can

be

disassembled after removing

transmission cover. Turn

up lip of

gear shift lever dust

cap and

remove

snap ring (4—Fig. AClOl), washer

(5),

and gear shift lever. Loosen shift-

er fork screws

and lug

screws

and

drive expansion plugs

out of

front

of

cover. Push shifter rods

(13, 17, and

18)

out

through front

of

cover

and

remove forks from bottom

of

cover

being careful

not to

lose detent balls

(7)

and

springs

(6)

from holes

in

cover

and

interlock plugs

(22) and

pin

(23)

from center shifter rod.

OVERHAUL. Procedures

for

over-

hauling the various parts

of

the trans-

mission unit

are

contained

in the fol-

lowing paragraphs:

226.

CLUTCH SHAFT. Clutch shaft

(1—Fig. AClOO)

is

positioned

by

snap

ring

(4) on

main drive gear bearing

6!2

Loading...

Loading...