ALLIS-CHALMERS

Paragraphs 227-229

outer race and can

be

pulled from

the

case after separating transmission from

the clutch housing as in paragraph 223.

To remove belt pulley bevel pinion

gear

(3)

and main drive gear bearing,

remove snap ring

(2)

and press pinion

gear and bearing

off

shaft.

Cork seals (7—Fig. AC75)

for

clutch

shaft which are located

in

clutch hous-

ing

can be

renewed

at

this time.

Reassembly

is

reverse

of

disassem-

bly.

Be

sure spigot bearing (main-

shaft pilot bearing) (20—Fig. AClOO)

is

in

position

on

mainshaft.

227.

MAIN (SPLINE) SHAFT.

Re-

moval

of

this shaft

(8)

requires

re-

moving transmission cover and discon-

necting rear

of

tractor from transmis-

sion case as described in paragraph 223.

Remove transmission rear bearing cap

(10)

and

pull mainshaft

(8),

bearing

and sleeve

(12) out

through

the

rear

of case while withdrawing sliding

gears from top

of

case. Spigot bearing

(mainshaft pilot bearing)

(20)

can

be

removed from pocket

in

clutch shaft.

Mainshaft rear bearing can

be

pressed

off shaft after driving riveted pin

(13)

out

of

sleeve

and

removing sleeve.

Reassembly

is

reverse

of

disassem-

bly. Install rear bearing

and

sleeve

on shaft and rivet sleeve retaining pin.

Be sure spigot bearing

and

spigot

bearing spacer

(19) are in

position

and insert shaft through rear

of

case

and install gears

on

shaft

as

follows:

First, second, and reverse sliding gear

(7) with groove toward front; third

and fourth speed sliding gear

(6)

with

groove toward rear.

228.

COUNTERSHAFT.

To

remove

this shaft,

it is

first necessary

to re-

move

the

clutch shaft,

and

mainshaft.

Then remove cap screw and lock plate

(21) from rear

of

case

and

bump

countershaft

out

toward

the

rear

and

withdraw gear cluster

(17)

through

the top

of

the case.

229.

REVERSE IDLER SHAFT.

To

remove this shaft

it is

first necessary

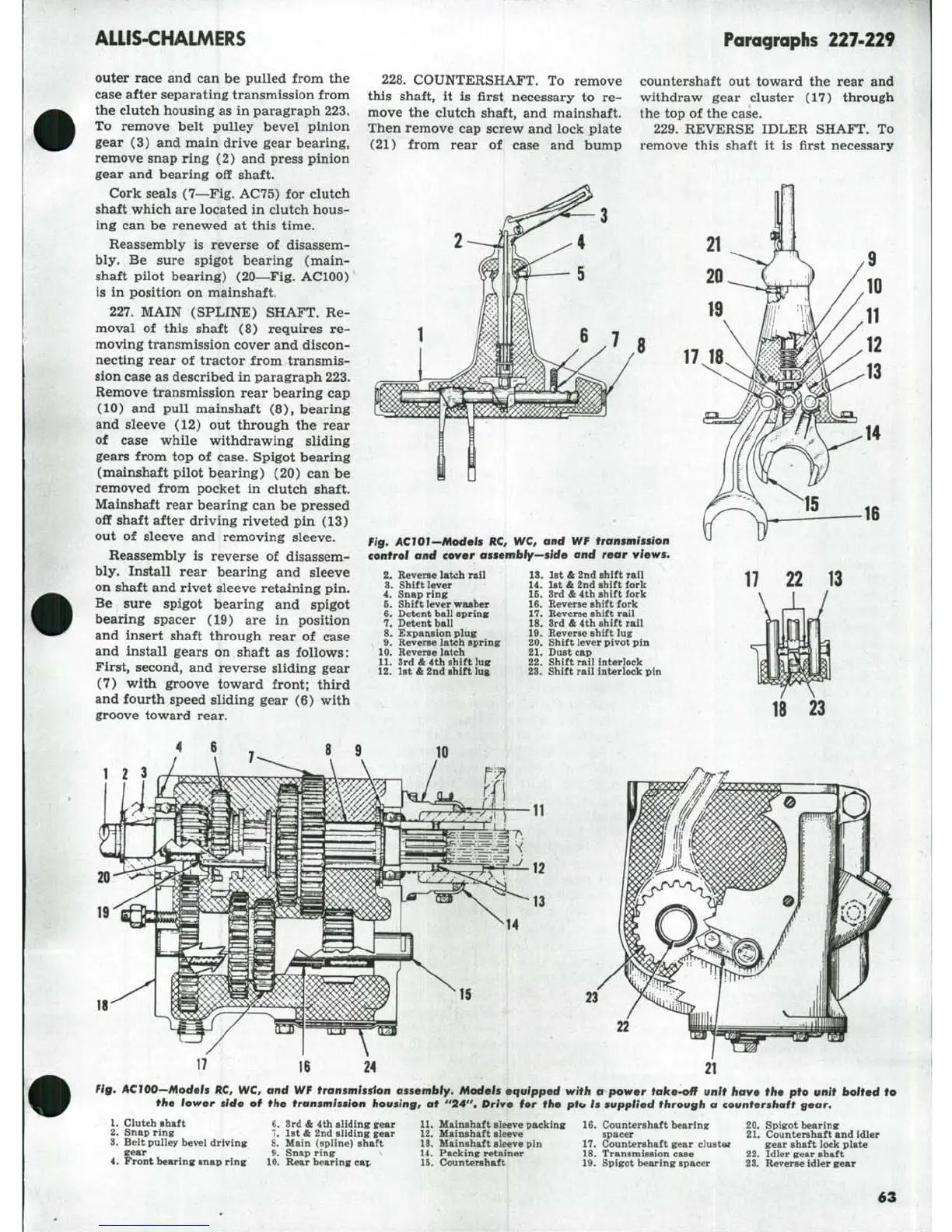

Fig, AClOl-Models HC, WC, and WF transmission

control and cover assembly^side and rear views.

17

18

16

10.

11.

12.

Reverse

latch rail

Shift

lever

Snap

rine

Shift

lever washer

Detent

ball sprins

Detent

ball

Expansion

plug

Reverse

latch spring:

Reverse

latch

3rd &

4th shift lus

1st &

2nd shift lug

13.

1st

&

2nd shift rail

14.

1st

&

2nd shift fork

16.

3rd

&

4th shift fork

16.

Reverse shift fork

17.

Reverse shift rail

15.

3rd

&

4th shift rail

19.

Reverse shift lug

20.

Shift lever pivot pin

21.

Dust cap

22.

Shift rail interlock

23.

Shift rail interlock pin

18

23

1

2

13

IS

24

22

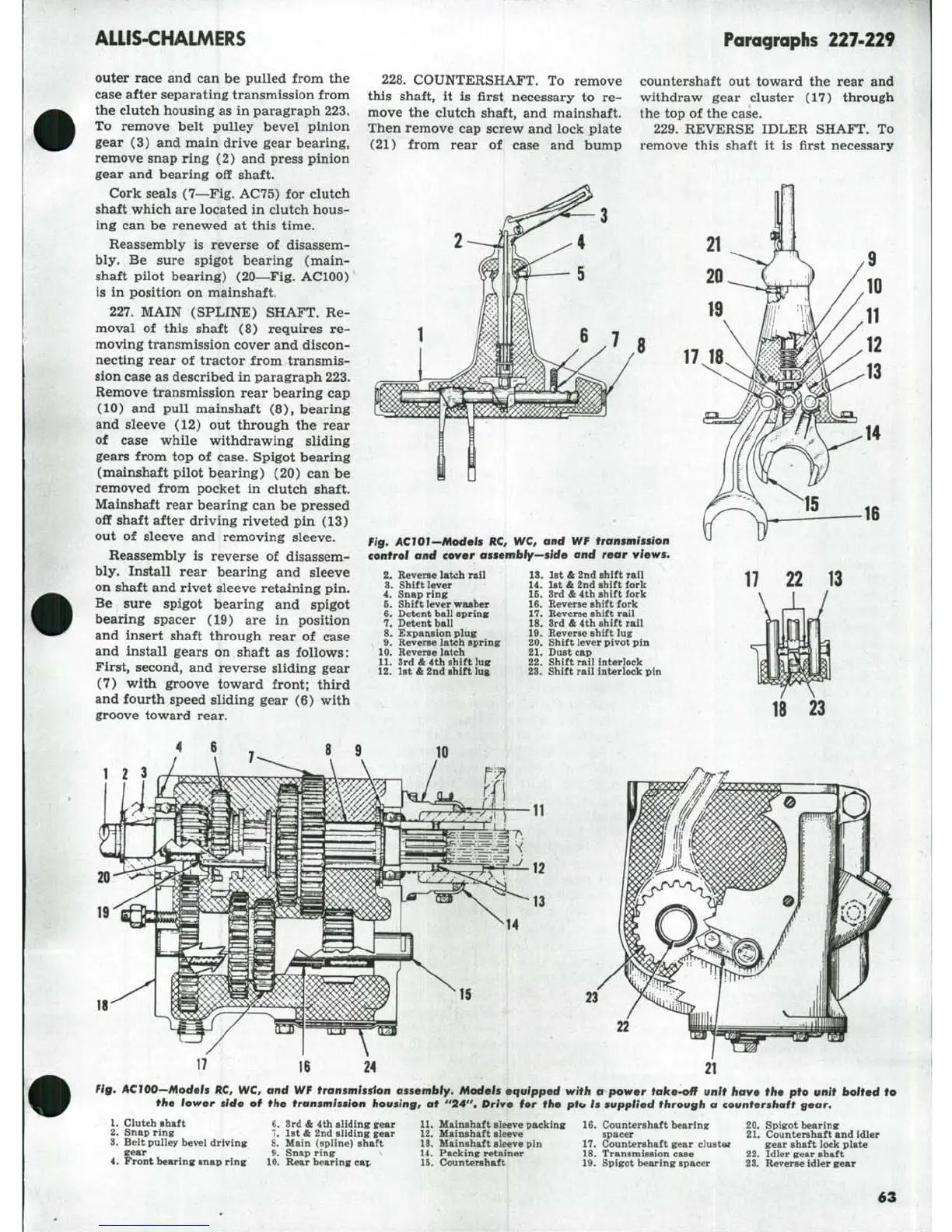

Fig, AClOO^Models ftC, WC, and WF

transmissiton

assembly.

Models equipped with a power take-off unit have the pto unit bolted to

the lower side of the transmission housing, at "24". Drive for the ptu Is supplied through a countershaft

gear.

U

Clutch shaft

2.

Snap ring

3.

Belt pulley hevel driving

gear

4.

Front bearing snap ring

6. 3rd

&

4th sliding gear

7.

1st

&

2nd sliding gear

8. Main (spline) shaft

9.

Snap ring

10.

Rear bearing cap

11.

Mainshaft sleeve packing

12.

Mainshaft sleeve

13.

Mainshaft sleeve pin

14.

Packing retainer

15.

C!ountershaft

16.

Countershaft bearing

spacer

17.

Countershaft gear cluster

18.

Transmission case

Id. Spigot bearing spacer

20.

Spigot bearing

21.

Countershaft and idler

gear

shaft lock plate

22.

Idler gear shaft

23.

Reverse idler gear

63

Loading...

Loading...